CNC Machining 101

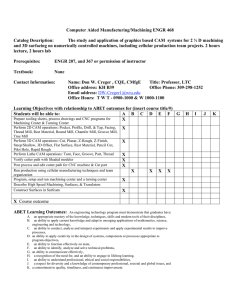

advertisement

An introduction to 3-axis CNC machining using the Blacktoe router Bo Pollett Neil Moloney 12/10/13 - 19:00 David Stewart Andrew Fred Briggs Robb Stacy 2.5D Machining Cuts profiles and pockets Drills holes 3D Machining Complex curvature Smooth surfaces Create large projects True 3D surfaces with accurate depths Dimensions are accurate to +/- .010 CNC operated from CAD model file Able to cut foam, plastic, wood, MDF, aluminum, and composites Can not undercut in a single operation Takes a long time to get smooth surfaces Can not cut very hard materials like Steel or Ti Requires more understanding and training than 2D machining like the laser cutter Requires attention or it will misbehave Ensure end mill does not hit a clamp/screw Ensure the feed is not so fast as to overheat the material or overstress the motor Stop the machine if there is an unexpected failure Bay size is 48 X 24 X 4 IN There is a 1 inch margin for machine operation on all sides so max material size is 47 X 23 X 2.5 IN The bay has provisions for clamps, but screws work better for harder materials Can be chucked with 1/8 or 1/4 end millsRPM Speed is 5000 – 28000 RPM Run Feed up to 100 in/min (faster is not always better) Has +/- .010 IN accuracy Can be jogged manually or by the computer Has built in vacuum provisions Has a electronic depth sensor Has emergency stops to prevent overrunning Z-Axis (2.5 IN) Cutting Bay Y-Axis (23 IN) Local (0,0) for the part X-Axis (47 IN) Cut out 2D shapes using a DXF file Minimum Inside radius Different end mill bits can create bevels, etc. Different depths can be used for engraving or pockets Gcode is crated in ArtCAM. For cutting flat sheet like carbon fiber or plywood there are several options Border and Raster This method created a smooth edge and leaves clean witness marks on the bottom of the part. This is useful for pocketing out areas in softer material since the bit will have to climb cut Radial Boundry This is the more common practice since the end mill will be in contact with a cutting edge in only one direction. This also cuts the inside first which reduces the chance for the part to slip. 6-8 R cutting depth to prevent cutter bending Various cutter styles can be used depending on the geometrical requirements When pocketing out an area, the end mill selection will determine if you have a flat bottom or a scalloped surface. Additionally, a ball nose end mill wil lcause all the inside corners to be radiused. Gcode for 3D parts is always raster in ArtCAM. You can select between raster in X, in Y, or in both. This will let you choose the direction of your “scallops”. Reducing the scallop effect can be accomplished through several methods which will be discussed in the next slides. http://www.arch.virginia.edu/arch549/handouts/artcam-toolpaths.html Bigger stepovers make rougher surfaces Smaller stepovers make smoother surfaces These are good for soft materials like foam that can be easily sanded later These are good for hard materials where big stepovers would cause too much heat buildup. Smaller stepovers allow for faster speed as well which compensates for the small amount of cutting on each pass. .75D Stepover .5D Stepover Creating inside corners that are larger than your end mill radius will ensure you do not bind in corners. Binding can cause bits to break, parts to shift, or poor surface finish. .25” Radius Inside Corner .375” Radius Inside Corner .25” Radius End Mills Cleaning – use the vacuum and brush to clean out all the areas where dust and debris can accumulate Ensure that all the tools and materials used are put away Empty the vacuum if it is getting full Record your time so we can keep the machine running Clamping can be used to hold light materials (soft or thin) Must be cut slowly or part will slide Dense or thick materials must be held with screws Jog the cutter to the extents of your tool path to check your work size so you don’t cut into a screw 0,0,0 can be set using the monitor or the hand controller Z=0 can be set at the top of your material or at the bottom Create a CAD model in Google Sketchup or other CAD program (.stl file) Create a toolpath in ArtCAM (.art file) Export the Gcode Run the Gcode in CNC USB (.tap file) ArtCAM CNC USB The mill has a spinning blade Don’t put your hand under the mill when running The mill is loud Use ear protection The mill likes to spit out debris Wear eye protection 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. 12. 13. 14. 15. 16. Create a CAD model as an .STL file Turn on computer and CNC board Import the File to ArtCam Align the model with the workspace Define the Toolpaths Generate the G code Import the G code into CAM operator Insert the proper end mill (use wrench and lock button) Zero the machine head Put on safety glasses and ear protection Turn on the vacuum and spindle Run the G code in CAM software Part cutting is complete and spindle returns to home Turn off spindle and vacuum Remove part and clean up area Log your time and turn off the computer CAD software Sketchup, Turbo CAD, AutoCAD, Inkscape, SolidWorks, Creo (Pro E), Catia CAM Software ArtCam, MasterCam, FreeMill, CamBam, PyCam Informational Sites Great source of terminology ▪ http://www.hsmworks.com/docs/cncbook/en/ ArtCAM walkthrough ▪ http://www.arch.virginia.edu/arch549/handouts/artcam-toolpaths.html ArtCAM tutorial videos ▪ http://www.youtube.com/user/delcamartcam ▪ http://www.artcam.com/videos-and-tutorials.asp CNC USB website ▪ http://www.planet-cnc.com/index.php?page=software CNC USB Tutorial ▪ http://www.planet-cnc.com/files/CNCUSBController.pdf We will use a STL file in ArtCAM to create a 3D raster Gcode file We will run the Gcode to trim styrofoam into a flying wing using raster along the streamline We will use ArtCAM to import dxf files of the outline of the keychains, The hole for the plastic inset, and the hole for the keyring Secure the material to the board Ensure safe operation (eye and ear protection) Cut the holes then the outline with a cutting bit Remove and clean station