Tooling - Schools

advertisement

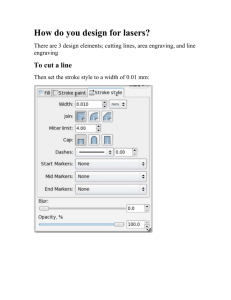

Tooling for CNC Milling Computer Integrated Manufacturing Unit 2 CNC Machining In this lesson Examine cutting tools and their recommended uses. Review the steps for setting up the tool library. Ball End Mill Basic Cutting Tools Combination Drill & Countersink Indexable Shell Mill Center Cutting End Mill Spotting Drill Non-Center Cutting End Mill Countersink Flutes 2 Flute End Mill More room for chip evacuation Used for light metals Weak, short tool life 4 Flute End Mill More cutting edges, longer tool life Used for harder metals Clogs easily in deep cuts Center vs. Non-Center Cutting 2 Flute Center Cutting 4 Flute Center Cutting 4 Flute Non-Center Cutting Milling Tools Tool Description ¼” 2 Flute HSS Single End Mills For Cutting Aluminum – 3/8 Shank x 1 ¼ cutting length ¼” 2 Flute Ball End Mill for Aluminum – 3/8 shank x 1 ¾ cutting length MSC Part # 01901164 71886162 Application Facing, profiling, Pocketing, Slotting, Roughing and Finishing Surfacing, Slotting, profiling, Roughing and Finishing Engraving Tool Options Tool Description MSC Part # Application ¼” Countersink & De-burring Tool – 90 Degree 02462166 Engraving, Deburring, countersink, Spot drilling #3 Combined drill & countersink 90 Degree 71037030 Spot drilling, Engraving ¼” spotting drill 90 deg Professional Development ID Code: 6005 01833003 Spot Drilling, Engraving Setting Up The Tool Library Type in a tool Enter the description Diameter Select the tool number. This will be identified as tool 1 (M06 T1) Fraction Decimal 1/16 0.0625 1/8 0.1250 3/16 0.1875 1/4 0.2500 5/16 0.3125 3/8 0.3750 7/16 0.4375 1/2 0.5000 9/16 0.5625 5/8 0.6250 11/16 0.6875 3/4 0.7500 13/16 0.8125 7/8 0.8750 15/16 0.9375 1 1.0000 Setting Up The Tool Library Select the type of Tool. A Bull Mill has a nose radius on its An End corners Mill has -aDefine flat bottom. A center cutting is the radius here. recommended since plunging is often required. Setting Up The Tool Library Define the taper angle. A Ball Mill has aDrill A Standard Define the constant(118° radius (1/2 Point) diameter at its Diameter) on its end point. end. An engraving tool is a type of tapered cutter. Setting Up The Tool Library Station Number – Defines the tool location for Automatic Tool Changers Various Suppliers http://www.coromant.sandvik.com/ http://www.kennametal.com/en/metalworking/mw_home.jhtml http://www.mscdirect.com http://www.penntoolco.com/main.cfm Curriculum Alignment: Unit 2 – CNC Machining Section 2.2 – CNC Characteristics 2.2.2 – Tooling References: Kibbe, R.R. & Neely, J.N & Meyer, R.O. & White, W.T. (2002). Machine Tool Practices, Upper Saddle River, NJ: Prentice Hall. Mattson, M. (2002). CNC Programming Principles and Applications, Albany, NY: Delmar. Credits: Writer: Ken McDermith Content Editor: Donna E. Scribner Narration: Donna E. Scribner PLTW Editor: Ed Hughes Production: CJ Amarosa Video Production: CJ Amarosa Audio: CJ Amarosa Project Manager: Donna E. Scribner