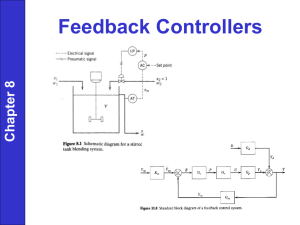

Chapter 8

advertisement

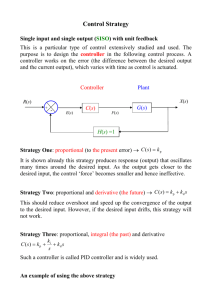

Chapter 8 Feedback Controllers Chapter 8 On-off Controllers • • • • Simple Cheap Used In residential heating and domestic refrigerators Limited use in process control due to continuous cycling of controlled variable excessive wear on control valve. Examples •Batch process control (PLC = programmable logic controller) •Solenoid in home heating unit •Sprinkler systems •Cruise control? On-Off Controllers Chapter 8 Synonyms: “two-position” or “bang-bang” controllers. e = error = set point – measured variable Controller output has two possible values. Chapter 8 Practical case (dead band) δ = tolerance system never reaches steady-state Chapter 8 Chapter 8 Three Mode (PID) Controller • Proportional • Integral • Derivative Proportional Control • Define an error signal, e, by e = Ysp – Ym where Ysp = set point Ym = measured value of the controlled variable (or equivalent signal from transmitter) Chapter 8 Since signals are time varying, e(t) = Ysp(t) - Ym (t) n.b. Watch units!! • For proportional control: p(t)= p + Kce(t) p = p - p where, p(t) = controller output p = bias value (adjustable) Kc = controller gain (dimensionless, adjustable) Chapter 8 Figures 8.4, 8.5 in Text Standards (ISO/ISA) 3 – 15 psi 4 - 20 ma 0 – 10 VDC Proportional Band, PB Chapter 8 100% PB Kc Reverse or Direct Acting Controller Kc can be made positive or negative Recall for proportional FB control: p(t)= p + Kce(t) or p(t) p K c Ysp (t) Ym (t) Direct-Acting (Kc < 0) “output increases as input increases" p(t) Ym(t) Reverse-Acting (Kc > 0) “output increases as input decreases" Chapter 8 • Example 2: Flow Control Loop Assume FT is direct-acting. Select sign of Kc so that KcKv > 0 1.) Air-to-open (fail close) valve ==> ? 2.) Air-to-close (fail open) valve ==> ? • Consequences of wrong controller action?? Chapter 8 Transfer Function for Proportional Control: Let p(t) p(t)- p Then controller input/output relation can written as p(t) Kce(t) Take Laplace transform of each side, P(s) K c E(s) or P(s) Kc E(s) INTEGRAL CONTROL ACTION Synonyms: "reset", "floating control" t 1 p( t ) p e( t)dt I 0 P(s) 1 E(s) Is I reset time (or integral time) - adjustable Proportional-Integral (PI) Control Chapter 8 t 1 p( t ) p K c e( t ) e( t )dt I 0 integral provides memory of e most popular controller • Response to unit step change in e: • Integral action eliminates steady-state error (i.e., offset) Why??? e 0 p is changing with time until e = 0, where p reaches steady state. P(s) 1 • Transfer function for PI control K c 1 Chapter 8 E(s) Is Some controllers are calibrated in 1/I ("repeats per minute") instead of I . Chapter 8 For PI controllers, p is not adjustable. Derivative Control Action Ideal derivative action de p( t ) p D dt Used to improve dynamic response of the controlled variable Derivative kick (use -dym/dt ) Use alone? Chapter 8 Proportional-Integral-Derivative (PID) Control Now we consider the combination of the proportional, integral, and derivative control modes as a PID controller. Chapter 8 • Many variations of PID control are used in practice. • Next, we consider the three most common forms. Parallel Form of PID Control The parallel form of the PID control algorithm (without a derivative filter) is given by 1 p t p K c e t τI de t 0 e t * dt * τ D dt t (8-13) The corresponding transfer function is: P s (8-14) Chapter 8 1 Kc 1 τDs E s τI s P s τ I s 1 τ D s 1 Kc E s τ s ατ s 1 I D (8-15) Expanded Form of PID Control In addition to the well-known series and parallel forms, the expanded form of PID control in Eq. 8-16 is sometimes used: t de t 0 dt Chapter 8 p t p Kc e t K I e t * dt * K D (8-16) Features of PID Controllers Elimination of Derivative and Proportional Kick • One disadvantage of the previous PID controllers is that a sudden change in set point (and hence the error, e) will cause the derivative term momentarily to become very large and thus provide a derivative kick to the final control element. Chapter 8 Automatic and Manual Control Modes Chapter 8 • Automatic Mode Controller output, p(t), depends on e(t), controller constants, and type of controller used. ( PI vs. PID etc.) Manual Mode Controller output, p(t), is adjusted manually. Manual Mode is very useful when unusual conditions exist: plant start-up plant shut-down emergencies • Percentage of controllers "on manual” ?? (30% in 2001, Honeywell survey) Chapter 8 Digital PID Controller D t n1 pn p K c en ek en en1 I k 1 t D I finite difference approximation where, t = the sampling period (the time between successive samples of the controlled variable) p n = controller output at the nth sampling instant, n=1,2,… en = error at the nth sampling unit velocity form - see Equation (8-19) (pn)- incremental change Chapter 8 Chapter 8 Typical Response of Feedback Control Systems Consider response of a controlled system after a sustained disturbance occurs (e.g., step change in disturbance variable); y > 0 is off-spec. No control (Kc=0) Increasing KC Chapter 8 y 0 Time Figure 8.13 Proportional control: effect of Controller gain y Increasing D 0 Time Figure 8.15 PID control: effect of derivative time Increasing I y Increasing KC y Chapter 8 0 0 Time (b) Time (a) Figure 8.14 Proportional-integral control: (a) effect of integral time, (b) effect of controller gain integral action ~ Kc / I Chapter 8 Summary of the Characteristics of the Most Commonly Used Controller Modes 1. Two Position: Inexpensive. Extremely simple. 2. Proportional: Simple. Inherently stable when properly tuned. Easy to tune. Experiences offset at steady state. (OK for level control) 3. Proportional plus integral: No offset. Better dynamic response than reset alone. Possibilities exist for instability due to lag introduced. Chapter 8 4. Proportional plus derivative: Stable. Less offset than proportional alone (use of higher gain possible). Reduces lags, i.e., more rapid response. 5. Proportional plus integral plus derivative: Most complex Rapid response No offset. Best control if properly tuned. Chapter 8 Example 3: Liquid Level Control • Control valves are air-to-open • Level transmitters are direct acting Chapter 8 Question: 1. Type of controller action? Select Kc so that K c Kv K p 0 (a) air-to-open valve: sign of Kv? (b) sign of process gain? Chapter 8 Previous chapter Next chapter