K d

advertisement

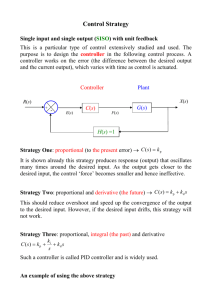

Low Level Control Control System Components The main components of a control system are The plant, or the process that is being controlled The controller, which controls the plant The measurement system, which is needed for feedback control Control Aim of control: making the plant respond to inputs in a desired manner. In a regulator-type control system the objective is to maintain the output at a desired (constant) value. In a servomechanism-type control system the objective is for the output to follow a desired trajectory. Types of Feedback Control Systems Linear versus Nonlinear Control Time-Invariant vs Time-Varying Continuous vs Discrete Open Loop Control If the plant is stable and is completely and accurately known, and if the inputs to the plant from the controller can be generated and applied accurately, accurate control will be possible even without feedback control. In this case the measurement system is not needed (or at least not needed for feedback) and thus we have an open-loop control system Control System Specifications Attribute Desired value Purpose Specifications Stability High The response does not grow without limit Percentage overshoot, settling time, and decays to the desired value pole (eigenvalue) locations, time constants, phase and gain margins, damping ratios Speed of response Fast The plant responds quickly to inputs Rise time, peak time, delay time, natural frequencies, resonant frequencies, bandwidth Steady-state Low error The offset from the desired response is negligible Error tolerance for a step input Robustness High Accurate response under uncertain Input noise tolerance, measurement conditions (signal noise, model error, etc.) error tolerance, model error tolerance and under parameter variation Dynamic interaction Low One input affects only one output Cross-sensitivity, cross-output transfer functions Performance Parameters Conventional Control Methods Proportional Integral Derivative Control Nonlinear Feedback Control Adaptive Control Sliding Mode Control Linear Quadratic Control H-Infinity Control Proportional (P) Control Using both the direction and the magnitude of the error allows the control system to respond in proportion to the error, and thus compensate for it more effectively. A proportional controller has an output o proportional to its input e: o = Kp * e where Kp is a proportionality constant. Gains Incorrect gain values will cause the system to undershoot or overshoot, i.e., not reach or go beyond the desired state. If a system cannot correct its gain incrementally, and it overshoots, it will do so repeatedly, resulting in oscillations. We use the term damping for systematically decreasing oscillations. A system is properly damped if it does not oscillate out of control Derivative (D) Control Setting gains is difficult, and simply increasing the proportional gain does not remove oscillatory problems in a control system. While at low values this may work, as the gain increases, the system's oscillations increase. The basic problem has to do with the distance from the set point/desired state: when the system is close to the desired state, it needs to be controlled differently than when it is far from it. A derivative controller has an output o proportional to the derivative of its input e: o = Kd * de/dt where Kd is a proportionality constant. Integral (I) Control This type of a system observes repeatable fixed steady state errors. It integrates them over time, and when they reach a threshold, moves the system in a direction to compensate for the errors. An integral controller has an output o proportional to the integral of its input e: o = Ki * e(t)dt ∫ where Ki is a proportionality constant. Proportional-Integral-Derivative Servo Control Characteristics of PID Control Controller Description Parameter Functions Undesirable side effects Kp Proportional gain Speeds up the response. System can become less stable Reduces offset. Reduces cross- (overshoot, oscillations, etc.) coupling Ki Integral time constant Reduces offset. Reduces noise Can slow down the system. Has a destabilizing effect. Introduces a phase lag Kd Derivative time constant Stabilizes the response (damping). Speeds up the system. Provides a phase lead (anticipatory effect) Enhances high frequency noise. Difficult to physically implement. Nonlinear Feedback Control Simple linear servo control is inadequate for transient and high speed operation of complex plants. Nonlinearities and dynamic coupling must be compensated faster than the control bandwidth. One method is feedback linearization. Model-Based Nonlinear Feedback Control System Adaptive Control A feedback control system in which the values of some or all of the control parameters are modified (adapted) during system operation on the basis of some performance measure when the output requirements are not satisfied. Model Reference Adaptive Control The same reference input applied to the plant is applied to the model. The difference between the response of the physical system and the output from the model is the error. The ideal objective is to make this error zero at all times. The reference model is an idealized model which generates a desired response at least in an asymptotic manner. Sliding Mode Control Linear Quadratic Gaussian Control An optimal control technique intended for linear systems with random input disturbances and output (measurement) noise H-Infinity Control Evaluation of Conventional Control Methods Advantages When the values of the controller parameters are known, the control signals are generated exactly. When the underlying assumptions are satisfied, many of these methods provide good stability, robustness to model uncertainties and disturbances, and speed of response. Disadvantages: The control algorithms are ''hard'' or “inflexible'' and cannot generally handle "soft'' intelligent control which may involve reasoning and inference making using incomplete, vague, not-crisp, and qualitative information, and learning and self-organization through past experience and knowledge.