slide show for lesson one

advertisement

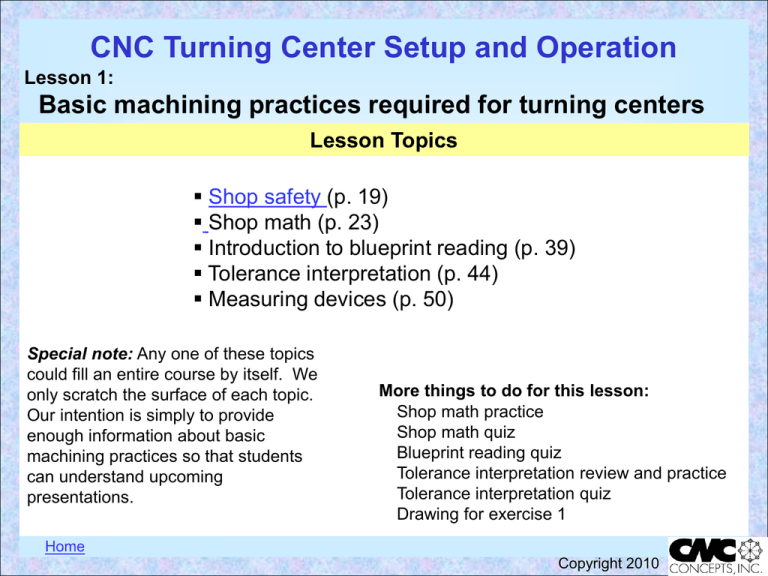

CNC Turning Center Setup and Operation Lesson 1: Basic machining practices required for turning centers Lesson Topics Shop safety (p. 19) Shop math (p. 23) Introduction to blueprint reading (p. 39) Tolerance interpretation (p. 44) Measuring devices (p. 50) Special note: Any one of these topics could fill an entire course by itself. We only scratch the surface of each topic. Our intention is simply to provide enough information about basic machining practices so that students can understand upcoming presentations. Home More things to do for this lesson: Shop math practice Shop math quiz Blueprint reading quiz Tolerance interpretation review and practice Tolerance interpretation quiz Drawing for exercise 1 Lesson topics Copyright 2010 CNC Turning Center Setup and Operation Lesson 1: Basic machining practices required for turning centers Shop safety A machine shop is a dangerous place! We cannot prepare you for every dangerous situation You must always be alert Safety equipment Protective eyewear Clothing Hearing protection Safety shoes Helmets Gloves Respirators and facemasks First aid kits Fire extinguishers Cranes and hoists Warning signs Home Lesson topics Safety practices When in doubt, ask! Raw material handling Heavy, sharp, greasy, slippery, dirty, sharp edges, chip residue, awkward shape Finished workpiece handling In addition to raw material handling: Hot Spring Tightening and loosening fasteners Getting around in the shop Behave in a professional manner No horseplay! Machining-center-specific safety issues Safety interlocks, guarding, signs, safe operating procedures Next topic: Shop math Copyright 2010 CNC Turning Center Setup and Operation Lesson 1: Basic machining practices required for turning centers Shop math Calculator recommendations Keep it simple Watch out for trick functions Avoid solar powered calculators Big buttons-big display Clear entry button Home Lesson topics Next topic: Blueprint reading Copyright 2010 CNC Turning Center Setup and Operation Lesson 1: Basic machining practices required for turning centers Shop math Arithmetic operations Most CNC operator work can be done with the four basic arithmetic operators: Add (+): 3 + 4 = 7 Subtract (-): 7 - 4 = 3 Multiply (X or *): 2 * 9 = 18 Divide (/): 20 / 2 = 10 Entries into CNC machines are done in decimal format (fractions are never used) 1/8 = 0.125 3/16 = 0.1875 You may be able to do some calculations in your head 20 / 2 = ? (20 divided by 2) 2.5 + 0.5 = ? 3.0 - 0.25 = ? 5.25 + 8.75 = ? 109.75 - 3.5 = ? But don’t hesitate to use your calculator if you’re in doubt 125.352 - 13.837 = ? Home Lesson topics Next topic: Blueprint reading Copyright 2010 CNC Turning Center Setup and Operation Lesson 1: Basic machining practices required for turning centers Shop math Arithmetic expressions An expression is a math question to be answered… Answer 3+4=7 Question 4+6–2=? 7–3+5=? 10 * 2 / 5 = ? (10 times 2 divided by 5) Home Lesson topics Next topic: Blueprint reading Copyright 2010 CNC Turning Center Setup and Operation Lesson 1: Basic machining practices required for turning centers Shop math Priority of arithmetic operations Consider this expression: 3 16 4 + 12 / 4 = ? 4 + 12 / 4 = ? What answer did you come up with? 4 plus 3 is 7 16 divided by 4 is 4, right? But wait a minute – there is another way to do this… Home Lesson topics Which answer is correct? Next topic: Blueprint reading Copyright 2010 CNC Turning Center Setup and Operation Lesson 1: Basic machining practices required for turning centers Shop math Priority of arithmetic operations With no other math “punctuation”… … division has a higher priority than addition 3 4 + 12 / 4 = ? 4 plus 3 is 7 The correct answer is 7 Home Lesson topics Next topic: Blueprint reading Copyright 2010 CNC Turning Center Setup and Operation Lesson 1: Basic machining practices required for turning centers Shop math Priority of arithmetic operations Order of arithmetic priorities: Parentheses can be used to specify operation order 1) 2) ( ) (4 + 12) / 4 = ? This makes it clear that 4 must be added to 12 first. Then the result (16) is divided by 4. The answer is 4. Home Lesson topics 3) 4) 5) 6) Anything in parentheses Functions (like square root, sine, cosine, tangent) Multiplication Division Addition Subtraction 3 * (4 + 2) = ? 5 + 0.5 / 2 = ? (8 + 2) / 5 = ? 7+9/2=? 4+1/2-2=? 8 * (2 + 3) / 2 = ? Next topic: Blueprint reading Copyright 2010 CNC Turning Center Setup and Operation Lesson 1: Basic machining practices required for turning centers Shop math Using a formula A formula is an arithmetic expression that contains variables rpm = 3.82 * sfm / tool diameter With this formula, consider this situation: You need to drill a 0.5 in diameter hole and the cutting tool manufacturer recommends 80 surface feet per minute. rpm = 3.82 * 80 / 0.5 rpm represents spindle revolutions-per-minute What rpm will you use? sfm represents speed in surfacefeet-per-minute tool diameter represents the diameter of the cutting tool Home Lesson topics Next topic: Blueprint reading Copyright 2010 CNC Turning Center Setup and Operation Lesson 1: Basic machining practices required for turning centers Shop math Measurement systems Some companies in the United States use the Imperial system Other companies use the Metric system (the Metric system is used almost exclusively in other countries) The inch is the most basic unit of distance in the machine shop The millimeter is the most basic unit of distance in the machine shop How big is an inch? How big is a millimeter? A deck of playing cards is about ½ an inch One inch = 25.4 millimeters Home Lesson topics The thickness of a quarterdollar is about one millimeter One millimeter = 0.0397 inches (about one-twenty-fifth of an inch) Next topic: Blueprint reading Copyright 2010 CNC Turning Center Setup and Operation Lesson 1: Basic machining practices required for turning centers Shop math Measurement systems To convert millimeters to inches: To convert inches to millimeters: inches = millimeters / 25.4 millimeters = inches * 25.4 How many inches is 350 millimeters? Home Lesson topics How many millimeters is 3.5 inches? Next topic: Blueprint reading Copyright 2010 CNC Turning Center Setup and Operation Lesson 1: Basic machining practices required for turning centers Shop math Decimal places A whole number is called an integer Consider this real number: A number containing a portion of a whole number is called a real number 4, 5, 8, 44, 103, 3,373, and 26,252 are examples of integers 3.274 is an example of a real number In a real number, the values to the right of the decimal point are called decimal places Home Lesson topics 5.436 There are three decimal places to the right of the decimal point With most CNC machines… Metric system allows up to three decimal places Imperial system allows up to four decimal places Next topic: Blueprint reading Copyright 2010 CNC Turning Center Setup and Operation Lesson 1: Basic machining practices required for turning centers Shop math Fractional format When using the Imperial measurement system (not the Metric system)… Some values may be specified with fractions Consider this fraction: 13/16 Pronounced as “thirteen-sixteenths” But a CNC machine cannot accept fractional format Divide 13 by 16 Fractions must be converted to decimal format 0.8125 (the result) is the decimal format of 13/16 To convert a fraction to decimal format, divide the numerator (top or left number) by the denominator (bottom or right number) Home Lesson topics Next topic: Blueprint reading Copyright 2010 CNC Turning Center Setup and Operation Lesson 1: Basic machining practices required for turning centers Shop math Saying numbers out loud in a machine shop In the Imperial measurement system: 1.0 : “one inch” 0.1 : “one-hundred-thousandths of an inch” 0.01 : “ten-thousandths of an inch” 0.001 : “one-thousandth of an inch” 0.0001 : “one tenth” (even though this value is really one ten-thousandth of an inch) More examples: 0.047 : “forty-seven thousandths” 0.250 : “two-hundred-fifty thousandths” 0.684 : “six-hundred-eighty-four thousandths” 1.455 : “one inch, four-hundred-fifty-five thousandths” 4.3723 : “four inches, three-hundred-seventy-two thousandths, and three tenths” Home Lesson topics Next topic: Blueprint reading Copyright 2010 CNC Turning Center Setup and Operation Lesson 1: Basic machining practices required for turning centers Shop math Saying numbers out loud in a machine shop In the Metric measurement system: 1.0 : “one millimeter” 0.1 : “one-hundred microns” 0.01 : “ten microns” 0.001 : “one micron” More examples: 0.047 : “forty-seven microns” 0.250 : “two-hundred-fifty microns” 0.684 : “six-hundred-eighty-four microns” 1.455 : “one millimeter, four-hundred-fifty-five microns” Home Lesson topics Next topic: Blueprint reading Copyright 2010 CNC Turning Center Setup and Operation Lesson 1: Basic machining practices required for turning centers Shop math Polarity All values have a polarity (plus or minus) With CNC machines, plus is always assumed If no polarity sign is specified (+ or -), the value is assumed to be positive All values shown to this point have been positive To specify a negative value, the minus sign (-) is used: -0.003 (negative three thousandths of an inch) When you subtract a number from a smaller number, the result will be negative 5.002 - 5.006 = -0.004 Home Lesson topics Next topic: Blueprint reading Copyright 2010 CNC Turning Center Setup and Operation Lesson 1: Basic machining practices required for turning centers Shop math Summary Most calculations required of setup people and operators are pretty simple The trick lies in doing simple calculations – over and over again – with out making any mistakes! Mistakes will, of course, result in scrap parts – or worse Home Lesson topics Next topic: Blueprint reading Copyright 2010