Right Skills Now webinar 3 28 12

advertisement

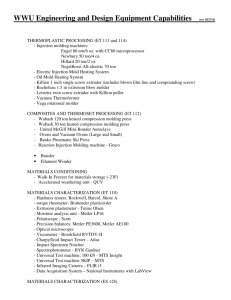

Right Skills Now: Bridge to Employment National Implementation of the NAM-Endorsed Skills Certification System Introductions and Proposal Partners Proposal Development Team Mid-South Community College • Dr. Glen Fenter, President • Dr. Sunny Morris, Liaison for Special Projects The Manufacturing Institute • Jennifer McNelly, President • Brent Weil, Senior Director for Education and Workforce 3 Proposal Context and Project Description The Skills Gap in Manufacturing 82% of manufacturers report a moderate-toserious skills gap in skilled production. 74% of manufacturers report that this skills gap has negatively impacted their company’s ability to expand operations. 69% of manufacturers expect the skills shortage in skilled production to worsen in the next 3-5 years. Deloite & The Manufacturing Institute, 2011 5 Manufacturers Need New Workforce Strategies Top sources for new employees 6 6 P R O V I D I N G C O M P E T E N C Y- B A S E D , C U S T O M I Z E D E D U C AT I O N A N D T R A I N I N G F O R T H E M A N U F A C T U R I N G W O R K F O R C E … T O D AY A N D T O M O R R O W 7 Project Construct & Management Management Structure 9 Roles and Responsibilities Mid-South Community College (Lead and Project Manager) • • • • • Consortium Applicant Fiscal Agent Data Collection and Reporting Participant Tracking (Seedco) Evaluation (SCATE) 10 Roles and Responsibilities Community College Partners • • • • • • • • Pathway Identification Skills Certification Curriculum Alignment Professional Development College Capacity Building Internship/OJT (grant funds may not pay direct wages) Student Outreach Data Entry for Participant Tracking ROI - Participant 11 Roles and Responsibilities The Manufacturing Institute (Technical Assistance & Implementation) • National Partner – Industry Sector Lead • Technical Assistance Implementation Support Best Practices ROI (Support) 12 Roles and Responsibilities The Manufacturing Institute Tools & Resources • • • • • Job Connection with US Manufacturing Pipeline Right Skills Now Model Student Engagement – Dream It, Do It NTER Learning Exchange Research Support and National Efforts (Jobs Council – Goal – NAS - NGA) • Prior Learning Assessment (CAEL) 13 Pathways and Certifications Baseline Co-Grantee Expectations All co-grantees will use the National Career Readiness Certificate as the baseline credential for workplace readiness Grantees will choose one or more pathways and implement one or more technical certifications Grantees will choose a traditional or accelerated pathway (Right Skills Now), or a combination 15 National Career Readiness Certificate Administered by ACT Three components: applied math, reading, using information Results in bronze, silver, gold, platinum certifications (silver is usually baseline for entry level) ACT has online content known as KeyTrain; this is not a requirement for the Right Skills Now proposal Some states have different branding – key is the ACT credential 16 Production Worker Skilled Maintenance Program Manufacturing Skills Standard Council (MSSC) Certified Production Technician: • Safety • Quality Practices & Measurement • Manufacturing Processes & Production • Maintenance Awareness 17 Machining National Institute of Metalworking Skills (NIMS) Machining Level I • • • • • • • • • • Measurement, Materials & Safety Job Planning, Benchwork & Layout Manual Milling Skills I Turning Operations: Turning Chucking Skills Grinding Skills I Drill Press Skills I CNC Turning: Programming Setup & Operations CNC Milling: Programming Setup & Operations CNC Turning: Operations CNC Milling: Operations 18 Welding American Welding Society Certified Welder 19 Engineering Society of Manufacturing Engineers (SME) Building to Certified Manufacturing Technologist (CMfgT) Certification or Certified Manufacturing Engineering (CMfgE) Certification (Or other foundational certifications including components of the CPT) 20 Fast Track to Jobs (Optional Model) Fast-Tracked, For-Credit Career Training Industry Credentials with Value in the Workplace Internships/Preference for Employment Pathways to Advancement and Degrees 21 2+2 Bachelor of Science Right Skills Now Model Associate of Applied Science (Machine Tool Technology AAS) 1 semester + internship • • • • Measurement, Materials and Safety Job Planning, Benchwork and Layout CNC Operator- Turning Level 1 CNC Operator- Milling Level 1 Job! Proposal Development Timeline & Co-Grantee Requirements Co-Grantee Template • Due April 18 Consortium Agreement • Signed by college president by April 23 Employer Partner Letter & Workforce System Partner Letter • Will be sent to colleges by April 4 to collect signatures • Due April 23 24 Co-Grantee Template Basic Information • College information & contact • Elements of SCS in place • Pathways to be built with grant funds 25 Co-Grantee Template Impact & Partnerships • TAA-impacted workers • Employer partners • WIB/One-Stop center partners • Real-time local data • Links to TAACCCT Round 1 grants • Articulation partners • State or local innovations to leverage 26 Co-Grantee Template Narrative • Brief description of the project • One paragraph per pathway 27 Co-Grantee Template Projected Outcomes • Total unique participants • Total completing TAACCCT-funded program of study • Total completing credit hours • Total retained in program of study • Total completing credit hours • Total earning credentials • Total enrolled in further education • Total employed • Total retained in employment • Total receiving wage increase 28 Co-Grantee Template Q&A on Template and Outcome Measures 29 Partnership Agreements Consortium Agreement • Will spell out roles, responsibility, budget framework, reimbursement agreements Employer partner letter • Standard letter with multiple signature lines Workforce system partner letter • Standard letter with multiple signature lines 30 Budget & Allowable Activities Draft College Budget Colleges will have $250,000 budget over 3 years covering: • Personnel $40,800/year • Travel • Contractual • Equipment/Supplies • Other – professional development, certification costs, and other miscellaneous expenses Flexibility on budget parameters 32 Allowable Expenses & Grant Activities It is expected colleges will expend funds on: • Project management • Intake and data entry (using Seedco tracking system) • Employer convening & engagement • Curriculum review & gap analysis • Curriculum development (minimum needed to fill gaps) • Alignment of coursework & programs of study • Alignment in for-credit tracks • Certification accreditation & testing facilities • Faculty certification expenses & release time • Minimal equipment expenses as may be needed to fill gaps • Job development, placement & follow-up 33 Unallowable Expenses Unallowable expenditures include: • Tuition payments, books & fees • Direct wage payments • Certification test costs These are generally included in tuition/lab fees 34 Discussion & Next Steps Contacts Brent Weil w: 202-637-3134 c: 703-869-5355 e: bweil@nam.org Sunny Morris w: 870-733-6860 c: 479-409-4790 e: smorris@midsouthcc.edu 36