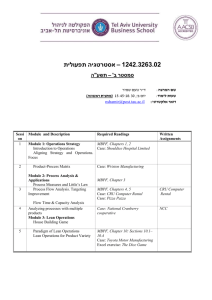

Flow Times - Kellogg School of Management

advertisement

Operations Management Process Analysis and Applications Module • Changing Sources of Competitive Advantage • Operational Measures: Time T, Inventory I, Throughput rate R • • • • Link through Little’s Law Link to Financial Measures Levers for Improvement CRU Computer Rentals • Capacity and Flow Time Analysis • Pizza Pazza • Levers for Improvement • Multi-product Capacity Management and Investment • Joint Marketing & Production Decisions • Optimal Capacity Investment • National Cranberry Cooperative 1 How can operations help a company compete? The changing sources of competitive advantage • Low Cost & Scale Economies (< 1960s) – You can have any color you want as long as it is black • Focused Factories (mid 1960s) • Flexible Factories and Product variety (1970s) – A car for every taste and purse. • Quality (1980s) – Quality is free. • Time (late 1980s-1990s) – We love your product but where is it? – Don’t sell what you produce. Produce what sells. P V Q T 2 Another example of financial flows at the corporate level: Mobile Handsets Data: – End of quarter inventory position from 10Q statements – Sales from income statement (smooth 9month avg.) How can financial flows help explain the difference in performance during the downturn? Nokia ($M) Inventory Sales per month (9 month avg) Time (months) Ericson ($M) Inventory Sales per month (9 month avg) Time (months) Motorola ($M) Inventory Sales per month (9 month avg) Time (months) 1999 12/31/99 $ 1,786 $ 1,437 1.24 $ 3,016 $ 486 6.20 $ 3,707 $ 1,088 3.41 3/31/00 $ 1,925 $ 1,437 1.34 $ 4,031 $ 486 8.29 $ 4,688 $ 1,088 4.31 2000 6/30/00 9/30/00 $ 2,290 $ 2,062 $ 1,437 $ 1,437 1.59 1.43 $ 4,612 $ 4,984 $ 486 $ 486 9.48 10.25 $ 5,446 $ 5,557 $ 1,088 $ 1,088 5.01 5.11 12/31/00 $ 2,014 $ 1,437 1.40 $ 4,671 $ 486 9.60 $ 5,242 $ 1,088 4.82 3/31/01 $ 1,985 $ 1,692 1.17 $ 4,667 $ 245 19.02 $ 4,533 $ 830 5.46 2001 6/30/01 $ 1,622 $ 1,692 0.96 $ 2,947 $ 245 12.01 $ 3,842 $ 830 4.63 9/30/01 $ 1,774 $ 1,692 1.05 $ 2,647 $ 245 10.79 $ 3,250 $ 830 3.91 3 Mobile Handsets: How explain the difference in performance? $6B Inventory Flow Time 20wks 18 $5B 16 Motorola $4B 14 Ericson 12 Ericson $3B 10 8 $2B Motorola 6 $1B Nokia 4 2 $- Nokia 0 8/28/99 12/6/99 3/15/00 6/23/00 10/1/00 1/9/01 4/19/01 7/28/01 11/5/01 8/28/99 12/6/99 3/15/00 6/23/00 10/1/00 1/9/01 4/19/01 7/28/01 11/5/01 4 Operational Performance Measures • • • • Flow time T Throughput rate R Inventory I Process Cost 5 Relating operational measures (flow time T, throughput R & inventory I) with Little’s Law ... ... ... Inventory I [units] Flow rate/Throughput R [units/hr] ... ... Flow Time T [hrs] • Inventory = Throughput x Flow Time I = RxT • Turnover = Throughput / Inventory = 1/ T 6 Process Flow Examples Customer Flow: Taco Bell processes on average 1,500 customers per day (15 hours). On average there are 75 customers in the restaurant (waiting to place the order, waiting for the order to arrive, eating etc.). How long does an average customer spend at Taco Bell and what is the average customer turnover? Monetary Flow: A major manufacturer sells $300 million worth of cellular equipment per year. Average amount in accounts receivables is $45million. How long does it take to process a sales order in accounts receivable? Job Flow: The Travelers Insurance Company processes 10,000 claims per year. The average processing time is 3 weeks. Assuming 50 weeks in a year, what is the average number of claims “in process”? 7 Process Flow Examples Is she right? A general manager at Baxter states that her inventory turns three times a year. She also states that everything that Baxter buys gets processed and leaves the docks within six weeks. Are these statements consistent? 8 EXAMPLE 3.2 : MBPF Inc. MBPF Inc. manufactures prefabricated garages. Purchase sheet material, forms and assembles the finished product. Each garage needs a roof, a base. Goal : To understand how long and where a $ spends time in MBPF process. Where should we improve the flow time? 9 MBPF Inc.: Consolidated Income Statement Net Sales 250.0 Costs and expenses Cost of Goods Sold Selling, general and administrative expenses Interest expense Depreciation Other (income) expenses TOTAL COSTS AND EXPENSES 175.8 47.2 4.0 5.6 2.1 234.7 INCOME BEFORE INCOME TAXES PROVISION FOR INCOME TAXES NET INCOME 15.3 7.0 8.3 RETAINED EARNINGS, BEGINNING OF YEAR LESS CASH DIVIDENDS DECLARED RETAINED EARNINGS AT END OF YEAR 31.0 2.1 37.2 NET INCOME PER COMMON SHARE DIVIDEND PER COMMON SHARE 0.83 0.21 10 MBPF Inc.: Balance Sheet CURRENT ASSETS Cash Short-term investments at cost (approximate mkt.) Receivables, less allowances of $0.7 mil Inventories Other current assets TOTAL CURRENT ASSETS 2.1 3.0 27.9 50.6 4.1 87.7 PROPERTY, PLANT AND EQUIPMENT (at cost) Land Buildings Machinery and equipment Construction in progress Subtotal Less accumulated depreciation NET PROPERTY, PLANT AND EQUIPMENT 2.1 15.3 50.1 6.7 74.2 25.0 49.2 Investments Prepaid expenses and other deferred charges Other assets TOTAL ASSETS 4.1 1.9 4.0 146.9 11 INVENTORY Raw materials (roof) Fabrication WIP (roof) Purchased parts (base) Assembly WIP Finished goods TOTAL 6.5 15.1 8.6 10.6 9.8 50.6 COST OF GOODS SOLD Raw materials Fabrication (L&OH) Purchased parts Assembly(L&OH) TOTAL Raw Materials (roofs) 50.1 60.2 40.2 25.3 175.8 Fabrication (roofs) Assembly Purchased Parts (bases) Finished Goods 12 MBPF Inc.: Flow Times Throughput R $/Year $/Week Inventory I ($) Flow Time T = I/R (weeks) Raw Materials Fabrication Purchased Parts Assembly Finished Goods 50.1 0.96 6.5 6.75 110.3 2.12 15.1 7.12 40.2 0.77 8.6 11.12 175.8 3.38 10.6 3.14 175.8 3.38 9.8 2.90 I = R*T 13 MBPF Business Process Flows $60.2/yr $50.1/yr $110.3/yr $6.5 Raw Materials (roofs) $40.2/yr $25.3/yr $15.1 $175.8/yr Fabrication (roofs) $8.6 $10.6 $9.8 Assembly Finished Goods $175.8/yr $40.2/yr Purchased Parts (bases) 14 MBPF Inc.: Flow Times Flow rate R ($/week) 5.0 3.38 2.12 Fabrication 0.96 0.77 Assembly Accounts Receivable Finished Goods Purchased Parts Raw Materials 11.12 6.75 7.12 3.14 2.90 5.80 Flow Time T (weeks) 15 CRU COMPUTER RENTALS (to be distributed in class) 16 Pizza Pazza: Flow Time Analysis 2. What is the minimum time to fill a rush order, assuming that all steps of the process are started only after the order is received? Without spending money, how would you reduce this response time? 3. What is the maximum number of orders that PP can fill per hour in steady state? 4. Assume that there are four orders waiting to be processed, Jean is just about to start mixing the sauce for another two pizzas (a fifth order) and Jacqueline is just about to start loading two pizza pans into the oven (a sixth order). A customer calls in with a new pizza order and wants to know when she can pick up her order. What due-date time should Jean promise assuming that she processes all orders in the sequence received? 18 Operational Measure: Flow Time Driver: Activity Times Critical Path: Theoretical Flow Time: Average Flow Time: 19 Most Time Inefficiency Comes from Waiting: Flow Times in White Collar Processes Industry Process Average Flow Time Theoretical Flow Time Flow Time Efficiency Life Insurance New Policy Application 72 hrs. 7 min. 0.16% Consumer Packaging New Graphic Design 18 days 2 hrs. 0.14% Commercial Bank Consumer Loan 24 hrs. 34 min. 2.36% Hospital Patient Billing 10 days 3 hrs. 3.75% Automobile Manufacture Financial Closing 11 days 5 hrs 5.60% 20 Levers for Reducing Flow Time • Decrease the work content of critical activities. – work smarter. – work faster. – do it right the first time. – change product mix. • Move work content from critical to non-critical activities. – to non-critical path or to “outer loop.’’ • Reduce waiting time. 21 A Recipe for Capacity Measurements Resource Unit Load Resource Capacity (time/job) Unit Capacity # of units Total Process Resource Capacity Utilization* * assuming system is processing at full capacity 22 A Recipe for Capacity Measurements Resource Unit Load Resource Capacity (time/job) Unit Capacity # of units Total Process Resource Capacity Utilization* * assuming system is processing at full capacity 23 Pizza Pazza: Flow Rate/Capacity Analysis 1. What is the minimum number of pizza pans needed to ensure that no order has to wait for a pan? 2. If the Jacqueline calls in sick one day, what is the maximum number of orders that PP can fill? 25 A Recipe for Capacity Measurements Resource Unit Load Resource Capacity (time/job) Unit Capacity # of units Total Process Resource Capacity Utilization* * assuming system is processing at full capacity 26 A Recipe for Capacity Measurements Resource Unit Load Resource Capacity (time/job) Unit Capacity # of units Total Process Resource Capacity Utilization* * assuming system is processing at full capacity 27 Pricing: Wages and Quantity Discounts 1. Assume Jean and Jacqueline decide to hire two employees to perform their respective tasks; each paid €8 per hour. What is the contribution margin (revenue variable costs) generated per hour of operation of the process if pizzas sell for €5 each? What is the minimum amount that Jean can charge per pizza, and still make a profit? – Resource cost = – Material cost = – Contribution margin if sale price is €5 = – Minimum sale price = 2. Is it worth offering any discount to encourage all orders to be for three pizzas? If so, how much? 28 A Recipe for Capacity Measurements Resource Unit Load Resource Capacity (time/job) Unit Capacity # of units Total Process Resource Capacity Utilization* * assuming system is processing at full capacity 29 Capacity Investments: Another oven? Task reallocation 1. The pizzas have become wildly popular and Jean feels that they can easily sell twenty pizzas per hour. To increase capacity, he is thinking of renting another industrial oven, which would cost €10 for each hour that the oven is used. Do you think it is worthwhile for Jean to rent the oven if the rest of the process is kept as is (assume that Jean and Jacqueline are doing the tasks)? What would be the contribution margin from each hour of operation of the process? – Resource cost = – Material cost = – Contribution margin if sale price is €5 = 2. Can you think of ways to increase profits by reallocating tasks 30 between the employees? A Recipe for Capacity Measurements Resource Unit Load Resource Capacity (time/job) Unit Capacity # of units Total Process Resource Capacity Utilization* * assuming system is processing at full capacity 31 Other factors affecting Process Capacity • Batch (Order) Sizes: – Is it worth offering any discount to encourage all orders to be for 3 pizzas if we have 2 ovens? If so, how much? • Product Mix: see later • other managerial policies ... 32 Operational Measure: Capacity Drivers: Resource Loads • (Theoretical) Capacity of a Resource • Bottleneck Resource • (Theoretical) Capacity of the Process • Capacity Utilization of a Resource/Process = throughput [units/hr] capacity [units/hr] 33 Levers for Increasing Process Capacity • Decrease the work content of bottleneck activities – work smarter – work faster – do it right the first time – change product mix • Move work content from bottlenecks to non-bottlenecks – create flexibility to handle tasks originally assigned to bottleneck – to non-critical resource or to third party • Increase Net Availability – work longer: increase scheduled availability – increase scale (invest) – increase size of load batches/reduce or eliminate setups & changeovers 34 Increasing Process Capacity in The Goal • “is to increase the capacity of only the bottlenecks” – “ensure the bottlenecks’ time is not wasted” • increase availability of bottleneck resources • eliminate non-value added work from bottlenecks – reduce/eliminate setups and changeovers • synchronize flows to & from bottleneck – reduce starvation & blockage – “ the load of the bottlenecks (give it to non-bottlenecks)” • move work from bottlenecks to non-bottlenecks • need resource flexibility – unit capacity and/or #of units. • invest 35 Product Mix Decisions: Pizza Pazza offers 2 pizza types Sale Price of thin crust: Cost of Materials: €5 €1.40 Sale Price of deep dish: Cost of Materials: €7.50 €1.90 Which of these two products should Jean push to customers that call in and are undecided? 36 A Recipe for Capacity Measurements Resource Unit Load Resource Capacity (time/job) Unit Capacity # of units Total Process Resource Capacity Utilization* * assuming system is processing at full capacity Suppose they take the same processing except that deep dish 37 require 5 min (vs 2) in sauce prep and 29 min (vs 15) in baking. Product Mix Decisions Margin of thin crust pizza = €3.60 Margin of deep dish pizza = €5.60 Margin per oven minute from thin crust = 2*€3.60 / 16 min = € 0.45/min Margin per oven minute from deep dish = 2*€5.60 / 30 min = € 0.36/min 38 National Cranberry Cooperative 39 Learning Objectives Module 2: Multi-Product Process Analysis & Apps • Manage better with the three key operational measures and an interfunctional macro process view of the organization: • Process measures: – Flow time manage critical activities – Capacity manage bottleneck resources • Levers for improving – Flow time manage critical activities – Capacity & Throughput • Process capacity depends on a zillion things – Effect of product mix decisions on process capacity • marginal contribution per unit of bottleneck capacity used – Bottleneck may shift on adding capacity diminishing returns to capacity investment 40