Wood Fundamentals

advertisement

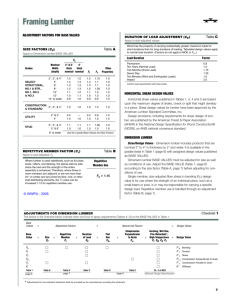

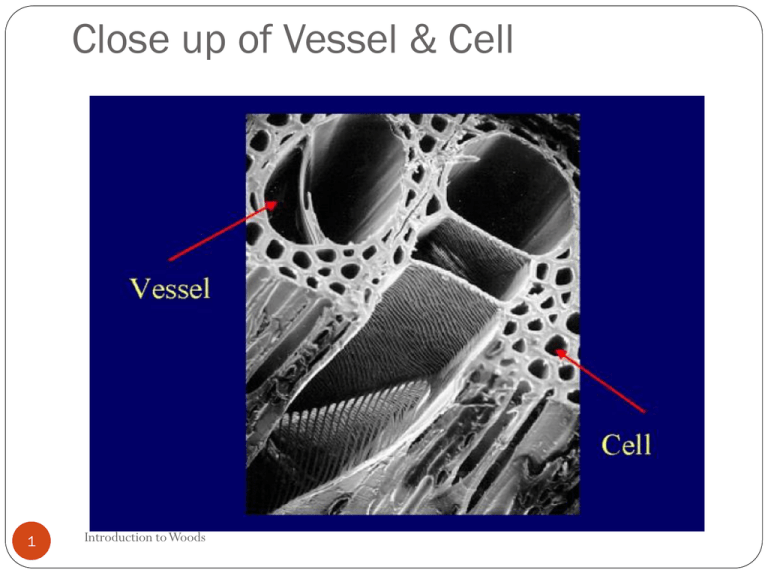

Close up of Vessel & Cell 1 Introduction to Woods Wood Behavior 2 Introduction to Woods Advantages of Wood 3 Introduction to Woods Disadvantages of Woods 4 Introduction to Woods Stresses Applied to Wood 5 Introduction to Woods Stress – Strain Relationship 6 Introduction to Woods Shrinkage & Swelling 7 Introduction to Woods Shrinkage & Swelling 8 Introduction to Woods Stress Grading 9 Introduction to Woods Stress Grading 10 Introduction to Woods Visual Grading 11 Introduction to Woods Machine Grading 12 Introduction to Woods Grading Organizations 13 Introduction to Woods Grading Lumber 14 Introduction to Woods 15 Properties of Wood and Lumber Grades Sawn Lumber: Wood members that have been manufactured by cutting a member directly from a log. Design values for sawn lumber depend on species group grade Load duration moisture content Size 16 Grading Structural Lumber Lumbers are graded based on size and number of growth (strength-reducing) characteristics they have (knots, checks, shakes, splits,...) 17 Grade Types 18 Introduction to Woods Grading Structural Lumber Visually Graded 19 Grading Structural Lumber Visually Graded WWP: Lumber Grading Agency 12 : Mill Number SEL STR: Lumber Grade DOUG FIR-L: Lumber Species S-GRN: Moisture Content Machine Stress Rated 1650:Nominal Bending Stress, psi 1.5E: Modulus of Elasticity, million psi 20 Sizes Categories There are three main size categories of lumber: Boards: 1 to 1 1/2” thick, 2” and wider Dimension lumber: 2 to 4” thick 2” and wider Timbers: 5” and thicker, 5” and wider Note 1: Thickness is the smaller cross sectional dimension and width is the larger dimension. Note 2: Dressed dimensions (S4S, Surfaced four Sides) are less than nominal dimensions (1.5”x3.5” for a 2x4). For stress calculations, dressed dimensions are used. 21 Dimension Lumber Joists and Planks Joists: 2-4 in thick and at least 6 in wide (graded based on bending strength on narrow edge) Planks: 2-4 in thick and at least 6 in wide (graded based on bending strength on wider dimension) Light Framing and Decking Light Framing: 2-4 in thick and 2-4 in wide (studs, joists and rafters) Decking: 2-4 in thick and 4 in or wider (used on their wider dimension) Timbers Beams and Stringers: at least 4”thick and at least 2” wider than they are thick; installed horizontally and ranked based on bending stress when loaded on the narrower dimension Posts and Timbers: have a width that is no more then 2” greater than thickness (square or nearly square); installed vertically and ranked based on compression parallel to the grain Design Values An important part of wood design is being able to determine design values for the following mechanical properties: Bending stress, Fb Tension stress parallel to grain, Ft Shear stress, Fv Compressive stress parallel to grain, Fc Compressive stress perpendic. to grain, Fc Modulus of Elasticity, E 24 Wet Service Factor (CM) Cont. The tabulated values for sawn lumber apply to members with EMC of 19% or less. If MC in service will exceed 19% for an extended period of time, the tabulated values are to be multiplied by CM (CM values are less than one and are given at the beginning of Table 4A). 25 Cr= Repetitive Member Factor A 15% increase in the tabulated Fb for repetitive-member systems is recognized in the NDS. A repetitive-member system is defined as one that has: 1.Three or more parallel members of dimension lumber 2. Members spaced not more than 24 in. o.c. 3. Members connected together by a load-distributing element such as roof, floor, or wall sheathing. 26 Cr= Repetitive Member Factor If one member should become overloaded, parallel members come into play. 27 28 29 30 31 32 33 34