measurements

advertisement

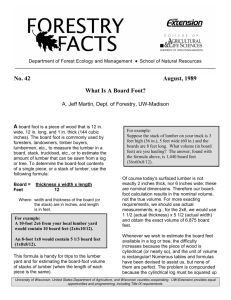

WOOD 120 Lumber volumes, measurements and sizes 1 Lumber volume • In sawmilling, lumber is most often measured by the “board foot” or “fbm” (foot board measure). 1fbm = 1 foot x 1 foot x 1 inch 2 Foot Board Measure 12 inches 1 inch Board foot = 12 inches wide, 12 inches long, 1 inch thick = 144 in3 = 1/12 ft3 3 Foot Board Measure • How many board feet in an eight foot long two by four? 4 Lumber volume In softwood sawmills Softwood lumber price is quoted in dollars per thousand board feet ( $ / Mfbm). Sawmill shift production is given in 100’s of thousand board feet. Sawmill capacity is given in million board feet (MMfbm). 5 Softwood • Largest BC sawmill production capacity 600 MMfbm • Average BC sawmill capacity approx. 200-250 MMfbm • Price of softwood lumber ≈ $350 /Mfbm 6 Softwood vs. Hardwood • Price of softwood lumber (e.g., SPF) $350 /Mfbm $0.35 / board foot • Price of hardwood lumber (e.g. sugar maple) $5 / board foot (for regular lumber) $30 / board foot (for figured lumber) 7 Lumber Recovery Factor (LRF) • Definition: LRF is the volume of green/rough sawn lumber that is produced out of a given input volume of logs. • The units of LRF are board feet per cubic meter. LRF typically ranges between 200 to 300 board feet per cubic meter. 8 Lumber Recovery Factor (LRF) LRF depends on: Qualityof logs Size of logs Equipment used in a mill 318 fbm/m3 296 275 254 233 212 Recovery % 50 55 60 65 70 75 (Theoretical 100% recovery = 423 board feet) 9 Impact of log size on LRF (Top diameter, nominal 2” production) (Wood Products Online Expo) 10 Fibre Recovery (sawmill) Chips Lumber Chips Sawdust Shavings Shrinkage 55% 25% 10% 5% 5% Shrinkage Shavings Sawdust Lumber 11 Utilization of harvested wood in North America Processed lumber 1970 38% 1985 41% 2005 Raw material Energy for other processes recovery 23% 16% 25% 52% Incinerated or landfill 23% 23% 36% 11% 11% (Dovetail Partners 2012) Average LRF (bf/m3) British Columbia Sawmill Lumber Recovery Factors Leading Mills 271 231 BC Mills +17% (BC Ministry of Forests, 2005) 13 Softwood lumber sizes Nominal size (inches) 2 4 6 8 10 1.5 3.5 5.5 7.25 9.25 Actual size (inches) 14 Lumber – target size Minimum dimension required to achieve desired final size given unavoidable reductions in size during manufacture. 15 Planer allowance Top head planer allowance Top head Final thickness Bottom head Bottom head planer allowance 16 Shrinkage allowance Lodgepole pine • Maximum potential shrinkage (30%mc to 0% mc) Tangential 6.8% Radial 4.7% • After drying to 15% mc (target max. is 19%mc) Tangential 3.4% Radial 2.4% • Assume higher possible shrinkage value • Possibility of over-drying (therefore excess shrinkage) 17 Target Size Minimum dimension required to achieve desired final size given unavoidable reductions in size during manufacture. 18 Lumber sizes • Actual size – real size of lumber (1.5 x 3.5) • Target size – minimum size that rough lumber can be cut to achieve required actual size (1.9 x 3.9) • Nominal size – traditional green size from which the name is derived (2 x 4) 19 Effect of sawing variability on target size frequency Mill A Mill B 1.70 1.72 1.74 1.80 Average thickness (in.) Target size component Final size Planing allowance Shrinkage Total process standard deviation Rough green target size Mill A 1.50 in. 0.150 in. 3% 0.015 in. 1.72 in. 1.90 Mill B 1.50 in. 0.150 in. 3% 0.060 in. 1.80 in. 20