Chapter 9: Phase Diagrams

advertisement

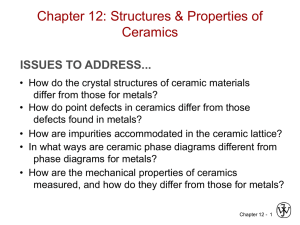

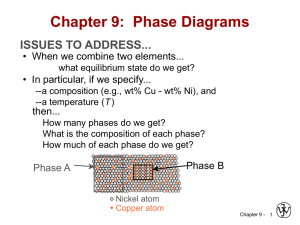

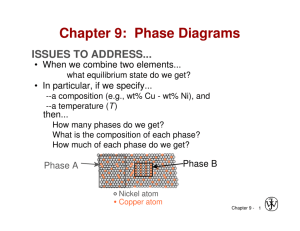

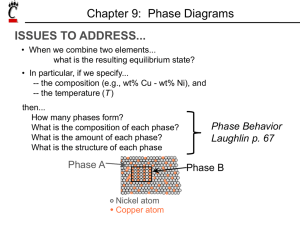

Chapter 9: Phase Diagrams ISSUES TO ADDRESS... • When we combine two elements... what is the resulting equilibrium state? • In particular, if we specify... -- the composition (e.g., wt% Cu - wt% Ni), and -- the temperature (T) then... How many phases form? What is the composition of each phase? What is the amount of each phase? Phase B Phase A Nickel atom Copper atom Chapter 9 - 1 Phase Equilibria: Solubility Limit • Solution – solid, liquid, or gas solutions, single phase • Mixture – more than one phase Adapted from Fig. 9.1, Callister & Rethwisch 8e. Sugar/Water Phase Diagram • Solubility Limit: (liquid) 60 L 40 (liquid solution i.e., syrup) 20 Answer: 65 wt% sugar. At 20ºC, if C < 65 wt% sugar: syrup At 20ºC, if C > 65 wt% sugar: syrup + sugar L 0 + S (solid sugar) 20 40 6065 80 100 C = Composition (wt% sugar) Sugar solubility limit for sugar in water at 20ºC? Solubility Limit 80 Water Question: What is the Temperature (ºC) Maximum concentration for which only a single phase solution exists. 100 Chapter 9 - 2 Components and Phases • Components: The elements or compounds which are present in the alloy (e.g., Al and Cu) • Phases: The physically and chemically distinct material regions that form (e.g., a and b). AluminumCopper Alloy Adapted from chapteropening photograph, Chapter 9, Callister, Materials Science & Engineering: An Introduction, 3e. b (lighter phase) a (darker phase) Chapter 9 - 3 Effect of Temperature & Composition • Altering T can change # of phases: path A to B. • Altering C can change # of phases: path B to D. B (100ºC,C = 70) D (100ºC,C = 90) 1 phase watersugar system Adapted from Fig. 9.1, Callister & Rethwisch 8e. Temperature (ºC) 100 2 phases L 80 (liquid) 60 L (liquid solution 40 i.e., syrup) + S (solid sugar) A (20ºC,C = 70) 20 2 phases 0 0 20 40 60 70 80 100 C = Composition (wt% sugar) Chapter 9 - 4 Criteria for Solid Solubility Simple system (e.g., Ni-Cu solution) Crystal Structure electroneg r (nm) Ni FCC 1.9 0.1246 Cu FCC 1.8 0.1278 • Both have the same crystal structure (FCC) and have similar electronegativities and atomic radii (W. Hume – Rothery rules) suggesting high mutual solubility. • Ni and Cu are totally soluble in one another for all proportions. Chapter 9 - 5 Phase Diagrams • Indicate phases as a function of T, C, and P. • For this course: - binary systems: just 2 components. - independent variables: T and C (P = 1 atm is almost always used). T(ºC) Phase Diagram for Cu-Ni system • 2 phases: 1600 1500 L (liquid) a (FCC solid solution) L (liquid) 1400 1300 a (FCC solid solution) 1200 1100 1000 0 20 40 60 80 • 3 different phase fields: L L+a a Adapted from Fig. 9.3(a), Callister & Rethwisch 8e. (Fig. 9.3(a) is adapted from Phase Diagrams of Binary Nickel Alloys, P. Nash (Ed.), ASM International, Materials Park, OH (1991). 100 wt% Ni Chapter 9 - 6 Isomorphous Binary Phase Diagram • Phase diagram: Cu-Ni system. • System is: T(ºC) 1600 1500 L (liquid) -- binary i.e., 2 components: Cu and Ni. -- isomorphous i.e., complete solubility of one component in another; a phase field extends from 0 to 100 wt% Ni. Cu-Ni phase diagram 1400 1300 a (FCC solid solution) 1200 1100 1000 0 20 40 60 80 100 wt% Ni Adapted from Fig. 9.3(a), Callister & Rethwisch 8e. (Fig. 9.3(a) is adapted from Phase Diagrams of Binary Nickel Alloys, P. Nash (Ed.), ASM International, Materials Park, OH (1991). Chapter 9 - 7 Phase Diagrams: Determination of phase(s) present • Rule 1: If we know T and Co, then we know: -- which phase(s) is (are) present. A(1100ºC, 60 wt% Ni): 1 phase: a B(1250ºC, 35 wt% Ni): 2 phases: L + a 1600 L (liquid) B (1250ºC,35) • Examples: T(ºC) 1500 1400 1300 A(1100ºC,60) 1100 1000 a (FCC solid solution) 1200 Adapted from Fig. 9.3(a), Callister & Rethwisch 8e. (Fig. 9.3(a) is adapted from Phase Diagrams of Binary Nickel Alloys, P. Nash (Ed.), ASM International, Materials Park, OH (1991). Cu-Ni phase diagram 0 20 40 60 80 100 wt% Ni Chapter 9 - 8 Phase Diagrams: Determination of phase compositions • Rule 2: If we know T and C0, then we can determine: -- the composition of each phase. • Examples: Consider C0 = 35 wt% Ni At TA = 1320ºC: Only Liquid (L) present CL = C0 ( = 35 wt% Ni) At TD = 1190ºC: Only Solid (a) present Ca = C0 ( = 35 wt% Ni) At TB = 1250ºC: Both a and L present CL = C liquidus ( = 32 wt% Ni) Ca = C solidus ( = 43 wt% Ni) Cu-Ni system T(ºC) A TA 1300 TB 1200 TD 20 tie line L (liquid) B D 3032 35 CL C0 a (solid) 4043 50 Ca wt% Ni Adapted from Fig. 9.3(a), Callister & Rethwisch 8e. (Fig. 9.3(a) is adapted from Phase Diagrams of Binary Nickel Alloys, P. Nash (Ed.), ASM International, Materials Park, OH (1991). Chapter 9 - 9 Phase Diagrams: Determination of phase weight fractions • Rule 3: If we know T and C0, then can determine: -- the weight fraction of each phase. • Examples: Consider C0 = 35 wt% Ni At TA : Only Liquid (L) present WL = 1.00, Wa = 0 At TD : Only Solid ( a) present WL = 0, Wa = 1.00 At TB : Both a and L present WL Wa S R +S 43 35 43 32 R = 0.27 R +S 0 . 73 Cu-Ni system T(ºC) A TA 1300 TB 1200 TD 20 tie line L (liquid) B R S D 3032 35 CL C0 a (solid) 40 43 50 Ca wt% Ni Adapted from Fig. 9.3(a), Callister & Rethwisch 8e. (Fig. 9.3(a) is adapted from Phase Diagrams of Binary Nickel Alloys, P. Nash (Ed.), ASM International, Materials Park, OH (1991). Chapter 9 - 10 The Lever Rule • Tie line – connects the phases in equilibrium with each other – also sometimes called an isotherm T(ºC) What fraction of each phase? Think of the tie line as a lever (teeter-totter) tie line 1300 L (liquid) B TB a (solid) 1200 S R 20 30CL C0 40 Ca wt% Ni WL ML ML Ma Ma ML Adapted from Fig. 9.3(b), Callister & Rethwisch 8e. S R S R 50 Ca C0 Ca CL S Ma x S ML x R Wa R R S C0 CL Ca CL Chapter 9 - 11 Ex: Cooling of a Cu-Ni Alloy • Phase diagram: Cu-Ni system. • Consider microstuctural changes that accompany the cooling of a T(ºC) L (liquid) 130 0 L: 35 wt% Ni a: 46 wt% Ni C0 = 35 wt% Ni alloy L: 35wt%Ni Cu-Ni system A 35 32 B C 46 43 D 24 L: 32 wt% Ni 36 120 0 a: 43 wt% Ni E L: 24 wt% Ni a: 36 wt% Ni a (solid) 110 0 20 30 Adapted from Fig. 9.4, Callister & Rethwisch 8e. 35 C0 40 50 wt% Ni Chapter 9 - 12 Cored vs Equilibrium Structures • Ca changes as we solidify. • Cu-Ni case: First a to solidify has Ca = 46 wt% Ni. Last a to solidify has Ca = 35 wt% Ni. • Slow rate of cooling: Equilibrium structure Uniform Ca: 35 wt% Ni • Fast rate of cooling: Cored structure First a to solidify: 46 wt% Ni Last a to solidify: < 35 wt% Ni Chapter 9 - 13 Mechanical Properties: Cu-Ni System • Effect of solid solution strengthening on: -- Ductility (%EL) 400 TS for pure Ni 300 TS for pure Cu 200 0 20 40 Cu 60 80 100 Ni Composition, wt% Ni Adapted from Fig. 9.6(a), Callister & Rethwisch 8e. Elongation (%EL) Tensile Strength (MPa) -- Tensile strength (TS) 60 %EL for pure Cu %EL for pure Ni 50 40 30 20 0 20 Cu 40 60 80 100 Ni Composition, wt% Ni Adapted from Fig. 9.6(b), Callister & Rethwisch 8e. Chapter 9 - 14 Binary-Eutectic Systems has a special composition with a min. melting T. 2 components Ex.: Cu-Ag system Cu-Ag system T(ºC) 1200 • 3 single phase regions L (liquid) 1000 (L, a, b) a L + a 779ºC • Limited solubility: TE 800 8.0 a: mostly Cu b: mostly Ag 600 • TE : No liquid below TE ab 400 • CE : Composition at temperature TE 200 • Eutectic reaction 20 a(CaE) + b(CbE) L(CE) L ( 71 . 9 wt% Ag) 0 cooling heating 40 L+b b 71.9 91.2 60 CE 80 100 C, wt% Ag Adapted from Fig. 9.7, Callister & Rethwisch 8e. a ( 8 .0 wt% Ag) b ( 9 1.2 wt% Ag) Chapter 9 - 15 EX 1: Pb-Sn Eutectic System • For a 40 wt% Sn-60 wt% Pb alloy at 150ºC, determine: -- the phases present Answer: a + b -- the phase compositions Answer: Ca = 11 wt% Sn Cb = 99 wt% Sn -- the relative amount of each phase Answer: S = W = R+S a 99 - 40 = 99 - 11 Wb = R = R+S 40 - 11 = 99 - 11 T(ºC) 300 200 59 = 0.67 88 C0 - Ca Cb - Ca = = 29 = 0.33 88 L (liquid) a L+ a 100 L+b b 183ºC 18.3 150 Cb - C0 Cb - Ca Pb-Sn system 61.9 R 97.8 S a+b 0 11 20 Ca 40 C0 60 80 C, wt% Sn 99100 Cb Adapted from Fig. 9.8, Callister & Rethwisch 8e. Chapter 9 - 16 EX 2: Pb-Sn Eutectic System • For a 40 wt% Sn-60 wt% Pb alloy at 220ºC, determine: -- the phases present: Answer: a + L -- the phase compositions Answer: Ca = 17 wt% Sn CL = 46 wt% Sn -- the relative amount of each phase Pb-Sn system T(ºC) 300 a 220 200 L (liquid) L+a R L+b b S 183ºC Answer: CL - C0 46 - 40 = Wa = CL - Ca 46 - 17 6 = = 0.21 29 C0 - Ca 23 = = 0.79 WL = CL - Ca 29 100 a+b 0 17 20 Ca 40 46 60 C0 CL 80 C, wt% Sn Adapted from Fig. 9.8, Callister & Rethwisch 8e. Chapter 9 - 17 100 Microstructural Developments in Eutectic Systems I • For alloys for which C0 < 2 wt% Sn • Result: at room temperature -- polycrystalline with grains of a phase having composition C0 T(ºC) 400 L a L 300 200 TE 100 Adapted from Fig. 9.11, Callister & Rethwisch 8e. L: C0 wt% Sn a L+ a a: C0 wt% Sn (Pb-Sn System) a+ b 0 10 20 30 C0 C , wt% Sn 2 (room T solubility limit) Chapter 9 - 18 Microstructural Developments in Eutectic Systems II • For alloys for which 400 2 wt% Sn < C0 < 18.3 wt% Sn • Result: at temperatures in a + b range 300 -- polycrystalline with a grains and small b-phase particles 200 L: C0 wt% Sn T(ºC) L L+a a TE a: C0 wt% Sn a b 100 Adapted from Fig. 9.12, Callister & Rethwisch 8e. L a a+ b 0 10 20 Pb-Sn system 30 C0 C, wt% 2 (sol. limit at T room ) 18.3 (sol. limit at TE) Sn Chapter 9 - 19 Microstructural Developments in Eutectic Systems III • For alloy of composition C0 = CE • Result: Eutectic microstructure (lamellar structure) -- alternating layers (lamellae) of a and b phases. T(ºC) L: C0 wt% Sn 300 Pb-Sn system a 200 L+ a L Lb b 183ºC TE 100 ab 0 20 18.3 Adapted from Fig. 9.13, Callister & Rethwisch 8e. Micrograph of Pb-Sn eutectic microstructure 40 b: 97.8 wt% Sn a: 18.3 wt%Sn 60 CE 61.9 80 160 m Adapted from Fig. 9.14, Callister & Rethwisch 8e. 100 97.8 C, wt% Sn Chapter 9 - 20 Lamellar Eutectic Structure Adapted from Figs. 9.14 & 9.15, Callister & Rethwisch 8e. Chapter 9 - 21 Microstructural Developments in Eutectic Systems IV • For alloys for which 18.3 wt% Sn < C0 < 61.9 wt% Sn • Result: a phase particles and a eutectic microconstituent L: C0 wt% Sn L T(ºC) 300 L Pb-Sn system a 200 a L+ a R TE L+ S S R a b b 0 20 18.3 Adapted from Fig. 9.16, Callister & Rethwisch 8e. primary a eutectic a eutectic b 40 60 61.9 • Just above TE : Ca = 18.3 wt% Sn CL = 61.9 wt% Sn S = 0.50 = Wa R+S WL = (1- Wa) = 0.50 • Just below TE : a+b 100 L 80 C, wt% Sn 100 97.8 Ca = 18.3 wt% Sn Cb = 97.8 wt% Sn Wa = S = 0.73 R+S Wb = 0.27 Chapter 9 - 22 Hypoeutectic & Hypereutectic 300 L T(ºC) Adapted from Fig. 9.8, Callister & Rethwisch 8e. (Fig. 10.8 adapted from Binary Phase Diagrams, 2nd ed., Vol. 3, T.B. Massalski (Editor-in-Chief), ASM International, Materials Park, OH, 1990.) a 200 L+ a a+b 20 40 hypoeutectic: C0 = 50 wt% Sn a a (Pb-Sn System) 100 0 (Figs. 9.14 and 9.17 from Metals Handbook, 9th ed., Vol. 9, Metallography and Microstructures, American Society for Metals, Materials Park, OH, 1985.) L+b b TE a 60 80 eutectic 61.9 hypereutectic: (illustration only) b b a Adapted from Fig. 9.17, Callister & Rethwisch 8e. C, wt% Sn eutectic: C0 = 61.9 wt% Sn a a 175 m 100 b b b b 160 m eutectic micro-constituent Adapted from Fig. 9.14, Callister & Rethwisch 8e. Adapted from Fig. 9.17, Callister & Rethwisch 8e. (Illustration only) Chapter 9 - 23 Intermetallic Compounds Adapted from Fig. 9.20, Callister & Rethwisch 8e. Mg2Pb Note: intermetallic compound exists as a line on the diagram - not an area - because of stoichiometry (i.e. composition of a compound Chapter 9 - 24 is a fixed value). Eutectic, Eutectoid, & Peritectic • Eutectic - liquid transforms to two solid phases L cool a + b (For Pb-Sn, 183ºC, 61.9 wt% Sn) heat • Eutectoid – one solid phase transforms to two other solid phases intermetallic compound - cementite S2 S1+S3 cool a + Fe3C (For Fe-C, 727ºC, 0.76 wt% C) heat • Peritectic - liquid and one solid phase transform to a second solid phase S1 + L S2 +L cool heat (For Fe-C, 1493ºC, 0.16 wt% C) Chapter 9 - 25 Eutectoid & Peritectic Peritectic transformation + L Cu-Zn Phase diagram Eutectoid transformation + Adapted from Fig. 9.21, Callister & Rethwisch 8e. Chapter 9 - 26 Iron-Carbon (Fe-C) Phase Diagram T(ºC) 1600 L + Fe3C - Eutectoid (B): a + Fe3C L 1400 1200 +L (austenite) 1000 a 800 A 1148ºC +Fe3C 727ºC = T eutectoid B a+Fe3C 600 120 m Result: Pearlite = alternating layers of a and Fe3C phases (Adapted from Fig. 9.27, Callister & Rethwisch 8e.) 400 0 (Fe) L+Fe3C 1 0.76 2 3 4 4.30 5 6 Fe3C (cementite) • 2 important points - Eutectic (A): 6.7 C, wt% C Fe3C (cementite-hard) a (ferrite-soft) Adapted from Fig. 9.24, Callister & Rethwisch 8e. Chapter 9 - 27 Hypoeutectoid Steel T(ºC) 1600 L a a a +L 1200 (austenite) 1000 + Fe3C 800 727ºC a a + Fe3C 600 pearlite 1 0.76 a 400 0 (Fe)C0 L+Fe3C 1148ºC 2 3 4 5 6 6.7 Adapted from Figs. 9.24 and 9.29,Callister & Rethwisch 8e. (Fig. 9.24 adapted from Binary Alloy Phase Diagrams, 2nd ed., Vol. 1, T.B. Massalski (Ed.-inChief), ASM International, Materials Park, OH, 1990.) C, wt% C 100 m pearlite (Fe-C System) Fe3C (cementite) 1400 Hypoeutectoid steel proeutectoid ferrite Adapted from Fig. 9.30, Callister & Rethwisch 8e. Chapter 9 - 28 Hypoeutectoid Steel T(ºC) 1600 L a +L 1200 (austenite) a a 1000 + Fe3C Wa = s/(r + s) 800 r s W =(1 - Wa) 727ºC aRS a + Fe3C 600 pearlite Wpearlite = W 400 0 (Fe)C0 1 0.76 a L+Fe3C 1148ºC Wa’ = S/(R + S) WFe3C =(1 – Wa’) pearlite 2 3 4 5 6 (Fe-C System) Fe3C (cementite) 1400 6.7 Adapted from Figs. 9.24 and 9.29,Callister & Rethwisch 8e. (Fig. 9.24 adapted from Binary Alloy Phase Diagrams, 2nd ed., Vol. 1, T.B. Massalski (Ed.-inChief), ASM International, Materials Park, OH, 1990.) C, wt% C 100 m Hypoeutectoid steel proeutectoid ferrite Adapted from Fig. 9.30, Callister & Rethwisch 8e. Chapter 9 - 29 Hypereutectoid Steel T(ºC) 1600 L Fe3C +L 1200 (austenite) 1000 L+Fe3C 1148ºC +Fe3C 800 a a +Fe3C 600 400 0 (Fe) pearlite 0.76 (Fe-C System) 1 C0 2 3 4 5 6 Fe3C (cementite) 1400 Adapted from Figs. 9.24 and 9.32,Callister & Rethwisch 8e. (Fig. 9.24 adapted from Binary Alloy Phase Diagrams, 2nd ed., Vol. 1, T.B. Massalski (Ed.-in-Chief), ASM International, Materials Park, OH, 1990.) 6.7 C, wt%C 60 mHypereutectoid steel pearlite proeutectoid Fe3C Adapted from Fig. 9.33, Callister & Rethwisch 8e. Chapter 9 - 30 Hypereutectoid Steel T(ºC) 1600 L +L 1200 (austenite) W =x/(v + x) WFe3C =(1-W) +Fe3C v x 800 a V 600 pearlite 400 0 (Fe) Wpearlite = W X 1 C0 Wa = X/(V + X) WFe 3C’ L+Fe3C 1148ºC 1000 0.76 Fe3C (Fe-C System) a +Fe3C 2 3 4 5 6 Fe3C (cementite) 1400 Adapted from Figs. 9.24 and 9.32,Callister & Rethwisch 8e. (Fig. 9.24 adapted from Binary Alloy Phase Diagrams, 2nd ed., Vol. 1, T.B. Massalski (Ed.-in-Chief), ASM International, Materials Park, OH, 1990.) 6.7 C, wt%C 60 mHypereutectoid steel =(1 - Wa) pearlite proeutectoid Fe3C Adapted from Fig. 9.33, Callister & Rethwisch 8e. Chapter 9 - 31 Example Problem For a 99.6 wt% Fe-0.40 wt% C steel at a temperature just below the eutectoid, determine the following: a) The compositions of Fe3C and ferrite (a). b) The amount of cementite (in grams) that forms in 100 g of steel. c) The amounts of pearlite and proeutectoid ferrite (a) in the 100 g. Chapter 9 - 32 Solution to Example Problem a) Using the RS tie line just below the eutectoid Ca = 0.022 wt% C CFe3C = 6.70 wt% C W Fe 3 C R RS C0 Ca C Fe 3 C C a 0 .40 0 .022 6 .70 0 .022 0 .057 1600 L 1400 T(ºC) 1200 +L 1000 Amount of Fe3C in 100 g = (100 g)WFe3C = (100 g)(0.057) = 5.7 g L+Fe3C 1148ºC (austenite) Fe C (cementite) b) Using the lever rule with the tie line shown + Fe3C 800 727ºC R S a + Fe3C 600 400 0 Ca C0 1 2 3 4 5 6 C, wt% C 6.7 CFe 3C Chapter 9 - 33 Solution to Example Problem (cont.) c) Using the VX tie line just above the eutectoid and realizing that C0 = 0.40 wt% C Ca = 0.022 wt% C Cpearlite = C = 0.76 wt% C 1600 V V X C0 Ca C Ca 0 .40 0 .022 0 .76 0 .022 0 .512 Amount of pearlite in 100 g = (100 g)Wpearlite T(ºC) 1200 +L L+Fe3C 1148ºC (austenite) 1000 + Fe3C 800 727ºC VX a + Fe3C 600 400 0 1 Ca C0 C = (100 g)(0.512) = 51.2 g 2 3 4 5 6 C, wt% C Chapter 9 - 34 Fe C (cementite) W pearlite L 1400 6.7 VMSE: Interactive Phase Diagrams Microstructure, phase compositions, and phase fractions respond interactively Change alloy composition Chapter 9 - 35 Alloying with Other Elements Ti Mo Si W Cr Mn Ni wt. % of alloying elements Adapted from Fig. 9.34,Callister & Rethwisch 8e. (Fig. 9.34 from Edgar C. Bain, Functions of the Alloying Elements in Steel, American Society for Metals, 1939, p. 127.) • Ceutectoid changes: Ceutectoid (wt% C) T Eutectoid (ºC) • Teutectoid changes: Ni Cr Si Ti Mo W Mn wt. % of alloying elements Adapted from Fig. 9.35,Callister & Rethwisch 8e. (Fig. 9.35 from Edgar C. Bain, Functions of the Alloying Elements in Steel, American Society for Metals, 1939, p. 127.) Chapter 9 - 36 Summary • Phase diagrams are useful tools to determine: -- the number and types of phases present, -- the composition of each phase, -- and the weight fraction of each phase given the temperature and composition of the system. • The microstructure of an alloy depends on -- its composition, and -- whether or not cooling rate allows for maintenance of equilibrium. • Important phase diagram phase transformations include eutectic, eutectoid, and peritectic. Chapter 9 - 37 ANNOUNCEMENTS Reading: Core Problems: Self-help Problems: Chapter 9 - 38