Carbon Fiber - WordPress.com

advertisement

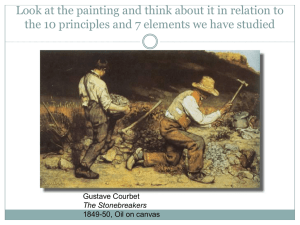

By: Group # 5 Kelvin John Hou Adrian Go Kyle Cheng Axel NgSy Carbon fiber is the common name used to refer to plastic reinforced by a graphite textile/reinforced polymer. The term is used to describe the textile itself, but it is pretty much useless unless embedded in plastic. Carbon fiber is known alternatively as carbon fiber reinforced plastic or carbon fiber composite. The plastic typically used is epoxy. Carbon fiber is very strong, light and expensive, but has a fantastic weightto-strength ratio. Attempts to put it into mass production have so far failed, due to inadequate demand, the customized nature of most carbon fiber parts, and a lack of skilled craftsmen. The material is employed in high-quality cars, boats, bicycles, and planes, including popular Formula One racecars. Similar to fiberglass (glass reinforced polymer), the composite material is commonly referred to by the name of its reinforcing fibers (carbon fiber). The polymer is most often epoxy, but other polymers, such as polyester, vinyl ester or nylon, are sometimes used. Some composites contain both carbon fiber and other fibers such as Kevlar, aluminum, and fiberglass reinforcement. In product advertisements, it is sometimes referred to simply as graphite fiber (or graphite It has many applications in aerospace and automotive fields, as well as in sailboats, and notably in modern bicycles and motorcycles, where its high strength-to-weight ratio is of importance. Improved manufacturing techniques are reducing the costs and time to manufacture, making it increasingly common in small consumer goods as well, such as laptops, tripods, fishing rods, paintball equipment, archery equipment, racquet frames, stringed instrument bodies, classical guitar strings, drum shells, golf clubs, and pool/billiards/snooker cues. Carbon fiber-reinforced polymer is used extensively in high-end automobile racing. The high cost of carbon fiber is mitigated by the material's unsurpassed strength-to-weight ratio, and low weight is essential for high-performance automobile racing. Racecar manufacturers have also developed methods to give carbon fiber pieces strength in a certain direction, making it strong in a load-bearing direction, but weak in directions where little or no load would be placed on the member. Conversely, manufacturers developed omnidirectional carbon fiber weaves that apply strength in all directions. This type of carbon fiber assembly is most widely used in the "safety cell" monocoque chassis assembly of high-performance racecars. Many supercars over the past few decades have incorporated CFRP extensively in their manufacture, using it for their monocoque chassis as well as other components. Until recently, the material has had limited use in mass-produced cars because of the expense involved in terms of materials, equipment, and the relatively limited pool of individuals with expertise in working with it. Recently, several mainstream vehicle manufacturers have started to use CFRP in everyday road cars. Use of the material has been more readily adopted by low-volume manufacturers who used it primarily for creating body-panels for some of their high-end cars due to its increased strength and decreased weight compared with the glass-reinforced polymer they used for the majority of their products. Carbon fiber-reinforced polymers have an almost infinite service lifetime when protected from the sun, and, unlike steel alloys, have no endurance limit when exposed to cyclic loading. When it is time to decommission Carbon fiber-reinforced polymers, they cannot be melted down in air like many metals. When free of vinyl (polyvinyl chloride) and other halogenated polymers, carbon fiber-reinforced polymers can be thermally decomposed via thermal depolymerization in an oxygen-free environment. This can be accomplished in a refinery in a one-step process. Capture and reuse of the carbon and monomers is then possible. CFRPs can also be milled or shredded at low temperature to reclaim the carbon fiber, however this process shortens the fibers dramatically. Just as with down cycled paper, the shortened fibers cause the recycled material to be weaker than the original material. There are still many industrial applications that do not need the strength of full-length carbon fiber reinforcement. For example, chopped reclaimed carbon fiber can be used in consumer electronics, such as laptops. It provides excellent reinforcement of the polymers used even if it lacks the strength-to-weight ratio of an aerospace component. http://en.wikipedia.org/wiki/Carbon_fiberreinforced_polymer http://image.made-inchina.com/2f0j00HCQtVOYsnekF/Carbon-FiberCar-Auto-Hoods-Bonnets.jpg http://elitechoice.org/wpcontent/uploads/2009/01/1-carbon-fiber-lotuselise1.jpg http://cdn.slashgear.com/wpcontent/uploads/2006/12/carbon-fibremacbook_011.jpg http://www.product-reviews.net/wpcontent/userimages/2007/09/the-tramontana.jpg Thank You Very Much! Thank You Very Much! Thank You Very Much! Thank You Very Much! Thank You Very Much! Thank You Very Much!