Electrospinning Technique

advertisement

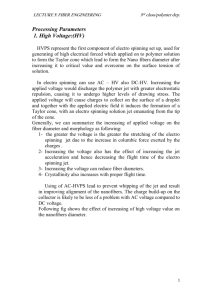

Electrospinning Technique by Assistant Professor Dr. Akram R. Jabur Dept. of Materials Eng. University of Technology Electrospinning Uses an electrical charge to draw very • fine fibres from a liquid. This method ensures that no solvent can be • carried over into the final product. Ability to produce novel synthetic fibers of • small diameter and good mechanical properties. Advantages Inexpensive and simple method Capable of producing nanofibers positive terminal negative terminal Taylor Cone refers to the cone observed in electrospinning, electrospraying and hydrodynamic spray processes from which a jet of charged particles emanates above a threshold voltage was described by Sir Geoffrey Ingram Taylor in 1964 before electrospray was "discovered“ to form a perfect cone required a semi-vertical angle of 49.3° (a whole angle of 98.6°) , the shape of such a cone approached the theoretical shape just before jet formation – Taylor Angle Taylor Cone When a sufficiently high voltage is applied to a • liquid droplet, the body of the liquid becomes charged, and electrostatic repulsion counteracts the surface tension and droplet is stretched, at a critical point a stream of liquid erupts from the surface. This point of eruption is known as the Taylor cone ELECTROSPINNING The distribution of charge in the fiber changes as the fiber dries out during flight ning Technique Advantages Able to make very thin fibers easily, since the • viscosity of many polymer solutions is very low. The lower viscosity of sample makes an • elongational deformation easily. Disadvantages The instability of • elongational deformation increases with growing deformation of low viscosity polymer solutions. Beads are more easily • formed as the fiber diameter decreases. Beads formation decreases the surface area of fabrics Process Electrospinning: • A high voltage is passed – through a polymer solution inducing an electrostatic repulsion force The polymer is pumped – through an insulin syringe, the repulsion force results in the formation of a thin jet This jet is directed toward a – grounded collection plate, the solvent evaporates before hitting the collection plate and results in the formation of a polymer scaffold Fiber dimension and morphology The diameter of a fiber produced by • electrospinning primarily depends on the spinning parameters. An increase in solution concentration results • in fibers with larger diameters. Parameters With increasing concentration of the fiber • content, increase in mechanical properties. But further increasing it, mechanical properties drops. With increasing electric potential the fiber • diameter decreases, and the fiber diameter distribution becomes increasing broader. Parameters 1. Molecular Weight of the polymer • 2. Solution properties (viscosity, conductivity and surface tension) 3. Electric potential, flow rate and concentration 4. Distance between the capillary and collection screen 5. Ambient parameters (temperature, humidity and air velocity in the chamber) 6. Motion of target screen (collector) 2 main Properties of fibers produced A very high surface to volume ratio • Defect free structure at the molecular level • Model of Surface-to-Volume Comparisons… Single Box Ratio 6 m2 = 6 m2/m3 3 1m Smaller Boxes Ratio 12 m2 = 12 m2/m3 3 1m Neglecting spaces between the smaller boxes, the volumes of the box on the left and the boxes on the right are the same but the surface area of the smaller boxes added together is much greater than the single box. • Nanofiber Structures Interconnected structure (Source: Ramakrishna, S., et.al, 2005) Filtration Polymeric nanofibers have significant applications in the area of filtration since their surface area is substantially greater and have smaller micropores than any other fibers like spun bond and melt blown (MB) webs. Fiber Type Fiber size, in micrometer Fiber surface area per mass of fiber material m2/g Polymeric Nanofibers 0.05 80 Spunbond fiber 20 0.2 Melt blown fiber 2.0 2 Potential Applications Tissue engineering scaffolds - Adjustable biodegradation rate - Better cell attachment - Controllable cell directional growth Wound dressing Medical prostheses - Prevents scar - Bacterial shielding - Lower stress concentration - Higher fracture strength Haemostatic devices Drug delivery - Higher efficiency in fluid absorption - Increased dissolution rate - Drug-nanofiber interlace Cosmetics - Higher utilization - Higher transfer rate Polymer Nanofiber Sensor devices - Higher sensitivity - For cells, arteries and veins Filter media Electrical conductors - Higher filter efficiency - Ultra small devices Protective clothing Material reinforcement Optical applications - Breathable fabric that blocks chemicals - Higher fracture toughness - Higher delamination resistance - Liquid crystal optical shutters NANOFIBERS Comparison of red blood cell with nanofibers web [1]. NANOFIBERS Entrapped pollen spore on nanofiber web [1].