Imaging methods in multi-phase flow research

advertisement

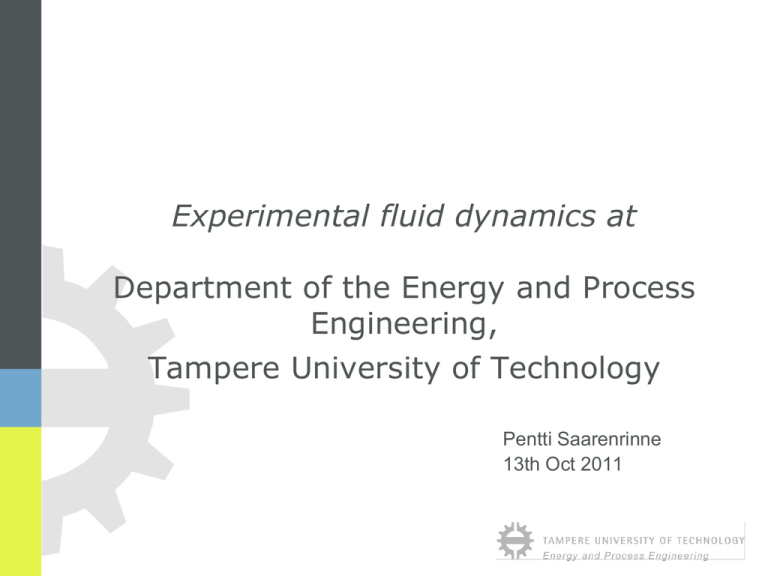

Experimental fluid dynamics at Department of the Energy and Process Engineering, Tampere University of Technology Pentti Saarenrinne 13th Oct 2011 Dept. of Energy and Process Engineering Figures • • • • Budget 3,6 M€ (1,7 +1,9 M€) 7 professors 30 researchers & research assistants 6 technicians Research topics • • • • Fluid Mechanics & Heat Transfer (CFD & Experimental) Paper converting and packaging Refrigeration Technology Combustion & Power Plant Technology The EFD group The group is specialized in optical measurement techniques in fluid mechanics and their adaptation to multiphase flows. Other research topics include turbulence, fluid-structure interactions, flow control, and mixing. The team: • Pentti Saarenrinne, Professor, D. Sc. (Tech) • Hannu Eloranta, D. Sc. (Tech.) moved to Pixact Ltd • Markus Honkanen, D. Sc. (Tech.) • Maria Putkiranta, M.Sc. (maternity leave) + M.Sc. students Measurement facilities For single-phase flows • PIV (three systems, including high-speed SPIV) • LDA For multi-phase flows • Direct imaging (high-speed & others) • PDA The laboratory has several water circulation loops, mixing tanks… Paper converting laboratory • Pilot plant (1 m width) • Laboratory Fiber suspension flows Simultaneous PIV and DI in a dilute fiber suspension flow Fiber suspension flows Simultaneous PIV and DI in a dilute fiber suspension flow Fiber orientation and flocculation measurements Experiments are conducted… The flow setup Fiber orientation measurements The effect of fiber consistency... C=0.02%-w C=0.1%-w C=0.5%-w Fiber orientation measurements The flocculation experiments • • Pine, 0.5%-w (mean length: 2.3mm, crowding factor: ~60) Two flow rates: 2.25 l/s (Uexit=5.0m/s) and 4.00 l/s (Uexit=8.5m/s) • Two channels Data collection • Images of the fiber phase were collected with two backlighting systems: • Double-frame camera operating at 4 Hz • High-speed camera operating at 1000-4000 Hz Floc orientation Mean floc size scale and aspect ratio Bubble analysis with 3D orthogonal imaging • Rising bubbles, frame rate 1000 1/s . • Orthogonal projections of the flow was achieved with a mirror system. • Automatic image analysis recognises bubbles, even when they are overlapping. . Ink removal from recirculated pulp suspension - Measurements in a flotation tank Submerged probe for the bubble size distribution in the inlet jet. Image analysis Air removal from fiber suspension in an open channel flow • Submerged measurement device sinking in suspension . •Bubble movement in a fiber suspension. •Blue broken lines are bubble path lines. The strain distributions inside a year ring during sudden compression in a split-Hopkinson device Objectives: • To develop an imaging and illumination method for the phenomena • The preparation of the wood samples to enable the measurement of the deformation inside a year ring • Measurement were made at elevated temperatures in a closed splitHopkinson device at Mid-Sweden University (Sundsvall). The strain distributions inside a year ring in sudden compression /2 With frame rate 50 000 1/s was imaged in one Compression a serie of 12 images. Results: • From the deformation images was computed strain maps. • The year rings of the sample are on the right hand side of the large strain areas. • The deformation in the ”spring” wood is bigger A Laboratory Scale CFB H x W x D: 3.0 x 0.4 x 0.015 m. Cold model. Fluidization velocities up to 4.0 m/s. Sauter mean diameters: 442 μm or 255 μm. •Particle size distribution was measured with shadowgraphy: High speed imaging at the bottom part of the model Frame rate300Hz Red arrow, velocity upwards 5 m/s, Blue arrow same velocity downwards testi image nr. 0 0 2.1 4.2 y [mm] 6.3 8.4 10.5 12.6 14.6 16.7 18.8 0 4.2 8.4 12.6 16.7 20.9 25.1 x [mm] testi-f16 image nr. 1 0 y [mm] 5 10 15 20.1 0 10 20.1 30.1 x [mm] 40.1 50.2 60.2 Thank you for your attention!