background and objectives of the project

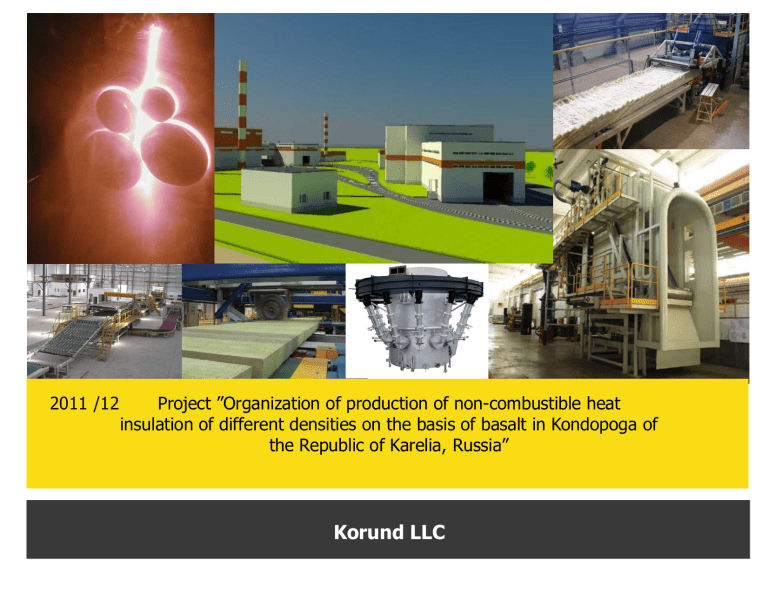

2011 /12 Project ”Organization of production of non-combustible heat insulation of different densities on the basis of basalt in Kondopoga of the Republic of Karelia, Russia”

Korund LLC

PRESENTATION CONTENTS

Background and objectives of the project

Basalt properties

Application of basalt products

Mineral wool products market in Russia

Geography of production distribution

Project implementation schedule

Investment indicators of the project

SWAT-analysis of the project

Appendixes:

General description of the production line and equipment

Production process

Проект “Организация производства негорючего утеплителя различной плотности на основе базальта в г.Кондопога, Республика Карелия Россия”

BACKGROUND AND OBJECTIVES OF THE PROJECT

Making basalt products fully complies with the tasks conducted by Government of the Russian

Federation of the development of innovative industries, energy saving and construction of new housing. Technologies for deep processing of mineral raw materials of magmatic rocks of basalt group are increasingly used in the world due to the fact that the basalt products have unique properties and are much cheaper than similar products from other materials. According to their properties, the benefits of basalt and its products in comparison to many other materials are endless, which makes it possible to use their amazing properties in various industries. Meanwhile the culture of using basalt products in Russia is considerably lower than in other economically developed regions of the world and rich reserves of raw basalt available in the country and scientific developments for its application have a huge potential.

Thus, today in Russia there is the possibility of implementing projects to produce basalt raw material products with unique properties and guaranteed demand in the long term prospect.

---------------------------------------------------------------------------------------------------------------------------

The objective of the project is organization of production of non-combustible heat insulation of different densities with subsequent release of basalt based products (superfine basalt yarns (rovings), basalt single crystal casting, etc.) based on the existing industrial site in Kondopoga of the Republic of

Karelia.

Проект “Организация производства негорючего утеплителя различной плотности на основе базальта в г.Кондопога, Республика Карелия Россия”

BASALT PROPERTIES

Basalts are common magmatic rocks on

Earth's surface.

BASALT PROPERTIES:

The porosity

Temperature resistance

4

Vapor permeability

Chemical resistance

The porosity of basalt fiber can be 70% of volume and more.

If pores of material are filled with air, then it is characterized by a small thermal conductivity at such porosity.

Temperature resistance is a very important property of thermal insulation materials, especially when used for insulation of industrial equipment operating at high temperatures.

Vapor permeability is the ability of the material to pass water vapor through its pores. In presence of interconnected pores in the materials of basalt fibers, they pass through the same amount of vapor like air. Due to high vapor permeability, these materials during the operation are almost always dry; condensation of vapor occurs mainly in the next layer on the colder side of the guardings.

Chemical resistance. Basalt fibers have good resistance to organic substances (oil, solvents, etc.), as well as to the action of alkalis and acids.

Проект “Организация производства негорючего утеплителя различной плотности на основе базальта в г.Кондопога, Республика Карелия Россия”

5

APPLICATIONS OF BASALT PRODUCTS

Applications

Aircraft industry Automobile production Mechanical engineering Shipbuilding

Military-industrial establishment

Agriculture and processing of agricultural production

Oil and gas industry

Cryogenic mechanics and equipment

Energetics Highway engineering Metallurgy Electrical engineering and communications

Coal, metal mining and enrichment industry

Civil and industrial engineering Protection of human environment

Chemical, petrochemical, by-product-coking, pulp and paper industry

Проект “Организация производства негорючего утеплителя различной плотности на основе базальта в г.Кондопога, Республика Карелия Россия”

MINERAL WOOL PRODUCTS MARKET IN RUSSIA

Production of heat insulation based on stone wool in Russia in 2007-2010 quarterly, thousand cubic meters:

Important! Despite the fact that the market for almost all building materials fell significantly after the crisis of 2008 and has not recovered to date, the market for stone wool heat insulation has managed to rise above pre-crisis volumes in just 3 quarters.

•

Manufacturers of mineral wool products in Russia:

Totally about 70 enterprises.

• Market leaders – URSA Eurasia with market share of 18,8%,

Saint-Gobain company has approximately the same share – 18,5%, top three is closed by Rockwool Russia which share is estimated as 8,6%.

• Total production of mineral wool products – thousand m³ (2009).

11 090,3

6

Rockwool

Technonikol

Thermosteps

Production volume over 500 th. m3 yearly

Isorock

Isomin

Tisol

Isovol

Linerock

Production volume over 100 th. m3 yearly

Komat etc.

Production volume over 100 th. m3 yearly

About 4% of companies

About 50% of companies

About 46% of companies

Проект “Организация производства негорючего утеплителя различной плотности на основе базальта в г.Кондопога, Республика Карелия Россия”

7

GEOGRAPHY OF PRODUCTION DISTRIBUTION

KONDOPOGA

GEOGRAPHY OF PRODUCTION

DISTRIBUTION

Given the logistics cost, competitive price can be achieved by distributing finished

product within a radius of 1000 km.

Thus the following major settlements potentially fall into the perimeter of distribution:

- Moscow and Moscow region,

- St. Petersburg,

- Tver,

- Arkhangelsk,

- Murmansk,

- Pskov,

- Velikiy Novgorod,

- Vologda

- Petrozavodsk.

Total population of these towns is about 20 million.

Distribution pathways:

- Railway, local railways owned by enterprises,

- Road transport, 2 km to the federal highway Moscow – Murmansk, St.

Petersburg – Murmansk

- Waterways during navigation using the piers of Lake Onega.

Проект “Организация производства негорючего утеплителя различной плотности на основе базальта в г.Кондопога, Республика Карелия Россия”

INVESTMENT INDICATORS OF THE PROJECT

Investment parameters:

Volume of investment: 2 257,8 mln. rub.

Own funds: 100 ÷ 350 mln. rub.

Investment loan: 1 950 ÷ 2 150 mln. rub.

PV revenue: 8 576 mln. rub.

NPV (10 years): 1 722 mln. rub.

PI: 1,87

IRR: 28,2

Discount rate: 15%.

Simple payback period: 54 months.

Discounted payback period: 69 months

Conclusion: The project is quite effective for PI and

NPV indicators, despite high discount rate (15%) it has an acceptable payback period (~ 4.5 years) and begins to generate positive cash flow in less than 2 years after the start of implementation (in 20 months).

8

ensitivity analysis NPV:

3 200 000,0

3 000 000,0

2 800 000,0

2 600 000,0

2 400 000,0

2 200 000,0

2 000 000,0

1 800 000,0

1 600 000,0

1 400 000,0

1 200 000,0

1 000 000,0

800 000,0

600 000,0

400 000,0

200 000,0

0,0

-30% -25% -20% -15% -10% -5% 0% 5% 10% 15% 20%

Изменение выручки

Proceeds change

Прямые расходы (сырьё)

Проект “Организация производства негорючего утеплителя различной плотности на основе базальта в г.Кондопога, Республика Карелия Россия”

SWAT-ANALYSIS OF THE PROJECT

Strengths

1. Close proximity of raw materials (10 km). Competitors in Vyborg,

Moscow, Nizhny Novgorod regions, Ryazan, Samara and others are forced to import raw materials from 500 to 1500 km.

2. Existence of own infrastructure (2 transformer substations with capacity of 5,3 MW, connected to Kondopoga hydropower plant with own cables, and 2 valve chambers for gas supply, own water intake).

3. Convenient transportation, possibility to deliver finished products by railroad, highway, waterway.

4. High profitability of the project.

5. Proximity of market in St. Petersburg and surrounding areas, as a rule being actively under construction and solvent.

6. Support of regional authorities.

7. Qualitative characteristics of the equipment to ensure the comparability of consumer properties of products with quality of products of recognized world leaders such as Danish ROCKWOOL or Finnish

PAROC.

Opportunities

Weaknesses

1. Initially high cost of the project, requiring large initial capital investments for modernization and construction of necessary infrastructure gaps.

2. Sufficiently long investment phase of the project related to the production of technological equipment (up to 1,5 years) by Italian company GAMMA MECCANICA

3. The project is implemented in an unstable macroeconomic environment: volatility of stock market, exchange rates of major world currencies, negative expectations of investors, etc.

Threats

1. A large area of the industrial site, which enables the organization to have additional activities in order to obtain additional income and diversify range of basalt products.

2. In period from 2011 to 2014 in the territory of the Republic of Karelia there is planned to implement a number of federal projects, projects of Shtokman gas field development and construction of Vidyaevo-Volkhov gas pipeline.

Kondopoga and industrial site of the company are located directly in the area of planned works, which makes it possible to use existing production, transport and engineering infrastructure in the implementation of this Federal Program.

1.

Emergence of new players – competitors in the market of heat insulation.

2. Geographical expansion of presence of existing competitors and their construction of new facilities.

3. Delay and reduction in the rate of construction in connection with the impact of the economic crisis.

9

Проект “Организация производства негорючего утеплителя различной плотности на основе базальта в г.Кондопога, Республика Карелия Россия”

10

Проект “Организация производства негорючего утеплителя различной плотности на основе базальта в г.Кондопога, Республика Карелия Россия”

General description of the production line and equipment

1. Raw materials drive assembly.

2. Weight distribution of raw materials assembly.

3. Smelting unit (electric furnace, gas furnace, cupola).

4. Fiber sedimentation chamber.

5. Synthetic binder drive assembly.

6. Polymerization chamber.

7. Mat cooling table.

8. Longitudinal and transverse cutting unit.

9. Stacker, packer.

10.Incinerator – unit for disposal of production emissions.

Flow chart of technological line on production of mineral wool (stone wool)

Reference data:

Technological production line of GAMMA MECCANICA (Italy)

Parameter

Guaranteed production of fiber

Minimal product density

Maximal density

Maximal mechanical speed of line

Minimal mechanical speed of line

11

Value

5,5 tons/hour

38000 tons/year)

35 kg/m3

220 kg/m3

33 m/min

1 m/min

Проект “Организация производства негорючего утеплителя различной плотности на основе базальта в г.Кондопога, Республика Карелия Россия”

Production process

12

Проект “Организация производства негорючего утеплителя различной плотности на основе базальта в г.Кондопога, Республика Карелия Россия”

Kondopoga

13

Проект “Организация производства негорючего утеплителя различной плотности на основе базальта в г.Кондопога, Республика Карелия Россия”

THANK YOU FOR YOUR ATTENTION

14

Проект “Организация производства негорючего утеплителя различной плотности на основе базальта в г.Кондопога, Республика Карелия Россия”