DMS Design

advertisement

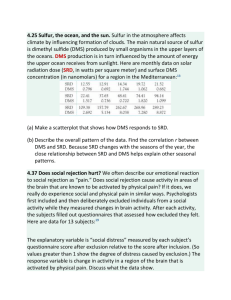

3CEMS DMS R&D Service Introduction DMS RD Dept. Updated Date: May, 2012 Confidential Overview DMS Team has over 10 years of experience in Industrial PC Field. We provide industrial grade products and solutions to meet the different extreme and tough environmental conditions. We specialize in fanless and wide temperature solutions. Our heat dissipation structure has U.S. patent. (Patent No. US7,468,555 B2) It makes our products 100% Fanless. 2 EMS+DMS Client Input Client Input DMS Design & Verification NPI EMS Build, QC & Deliver EMS Build, QC & Deliver 3 Supportable DMS Project Type 4 DMS R&D Design Introduction 5 Top-grade Products Design Others Material Requirements Wide Temperature Design System Test Layout System Design Requirements Signal P.C.B Measure Requirements 6 Design Overview • Components selection • Layout • PCBA Conformal Coating – Silicone for Anti-vibration, Wide Temp in Vehicle Computer • Wide Temperature Design • Wide Voltage Design (9-32V) • Water /Dust/ Salt Fog Resistance(Environmental) – Passed MIL-STD-810G Tests • Sunlight Readable Solution • Fanless / Cableless Embedded System Design • Anti-shock & Vibration Embedded System Design 7 Material Requirements Quality Improvment Wide temperature components selection (-30~+70) Passive parts Active parts Peripheral Others Resistor Easy Diode Easy Memory Selection Cable Easy Inductor Easy Transistor Easy Flash Selection Connector Selection Capacitor POSCAP/TAN MOSFET Easy HDD/SSD Selection Switch Selection CPU & ASIC Selection PANEL Selection Ensures all of the components can work in a wide-temp environment Design phase 8 Wide Temperature Design Quality Improvment Wide Temperature Design High efficient PWM design Sensitive PLL circuit design Hi-speed circuit design Balance performance and power consumption Design phase Talented Engineer 9 P.C.B Requirement Quality Improvment Checks all of the impedance to fit requirements Make PCB phase Slice PCB 10 Thermal Design Truly FANLESS, Patent for Thermal Design Material Technology Nano Paint: Water proof & Anti-heat Ceramics Paint Anti-vibration & Drop Design Anti-Vibration, Removable HDD Design Anti-Vibration, Anti-Shock System Design Fanless(Wide Temp.) Anti-Vibration(Rugged/IP) MIL-SDT-810F C3 Pass (Operational Vibration) Crash & Shock 14 Vibration – Vehicles MPC 900 Embedded computer 15 Vibration – Wheeled Trailer / Truck 16 Vibration – Wheeled Trailer / Truck 17 Industrial Grade Product Design for Mission Critical 18 Dust & Water Resistance 19 Sunlight Readable Core Technology (Increase Contrast Ratio) Increase LCD Brightness Normally, the utilization rate from light bar to surface is only 5% Increase light bar brightness Change materials Decease the sunlight reflection Add Anti-Reflection and ¼ lambda Films Change materials 20 Signal Measure Quality Improvment Critical signal’s eye pattern check During system design 21 Verification Requirement Burning & Memory Test Memory Test Burning Test 22 Verification Requirement Power Cycle Test Power Cycle 23 R&D Design Verification Testing Facility 24 Compelete RD Testing Equipments 25 IR Thermal Image Scan IR camera: FLIR Thermal CAM SC2000 Hot spots identified as the monitor points in system thermal test Hot spots are all under the components thermal specs 26 Climatic Stressing To simulate the worst environmental conditions with regard to temperature, humidity, etc. 27 Safety pre-test Dielectric Withstand/Insulation Resistance Test (Hi-Pot test) Ground Bond Tester limited power sources test Touch current test Steady force test Reflection test Enclosure opening test Accessibility test Impact test Stability test 3CEMS Confidential 28 Transprotation Simulation To simulate transportation impact to provide system /device within good condition during shipping Vibration Shock impact Handling impact 29 Manufacturing Capabilities Advanced Process Technology Surface Mounting Technology Process Large Scale SMT Capacity Double Side Component Capability VAD & RAD Capabilities High Speed & Efficient Machine Multiple & Flexible M/C Combination Circuit Board Fabrication Material Bar-Coding System Automated & Manual Insertion Automated Conformal Coating Clean & Lead-Free (RoHS) Process Specific Testing Service tailored for customers Full System Assembly 30 Manufacturing Capabilities World-Class Production Facilities Latest Manufacturing Techniques + State-of-the-Art Test Equipment = Top-Grade Products 31 DMS Design Capability – ID & ME Embedded Computer / Controller Mobile DVR Digital Signage Rugged Fanless Embedded Computer Rugged Fanless I/O Controller Design Capability for Rugged, Fanless, Cable less, Industrial Embedded I/O Controller & Computers. DMS Design Capability – ID & ME Panel PC / POS / IPC Monitor Design capability for Rugged, Industrial Panel PC, POS System & IPC Monitor Panel PC Product 12” - 15” 8” - 10” Robust Panel PC/POS, Monitor, ARM HCI Mobile handheld for Mission Critical in Military, Medical, Outdoors. Panel PC Product Panel Size : 17” Maritime Panel PC For Offshore, Cruise, Oil drill platform applications. Use for Sea Map, Navigation Monitors or Bridge Controller display Applications: River Cruise 35 Sunlight Readable Smart Panel Module 36 DMS Design – ID Design External HDD Enclosure External HDD Enclosure Multimedia Door Phone Door Phone DMS Design Capability – ID & ME Panel PC/POS/IPC Monitor Strong R&D experiences to fulfill customize needs On-going Project – 12” Panel PC (ODM) Delicate experienced R&D center locate in Taiwan System Design Capability: SAVE Manpower resources = SAVE COST One Stop Service Changeable Decoration Front Bezel • Design Quality Assurance • Fast and quick response • Testing Labs, Verifications • Tooling Molding benefits • Local supply chain links • One stop manufacturing 39 DMS Design – ID & ME Design Medical Equipment Direct phone in emergency With fingerprint module, control board, batteries, motor and mechanical linkage structure DMS Design – ID & ME Design Thermostat / LED Bulb Thermostat Battery charger LED bulb with heat spreading cooler Expansion card module