GE Adds Portable Basic Thickness Gauge to its Versatile DMS Go+

advertisement

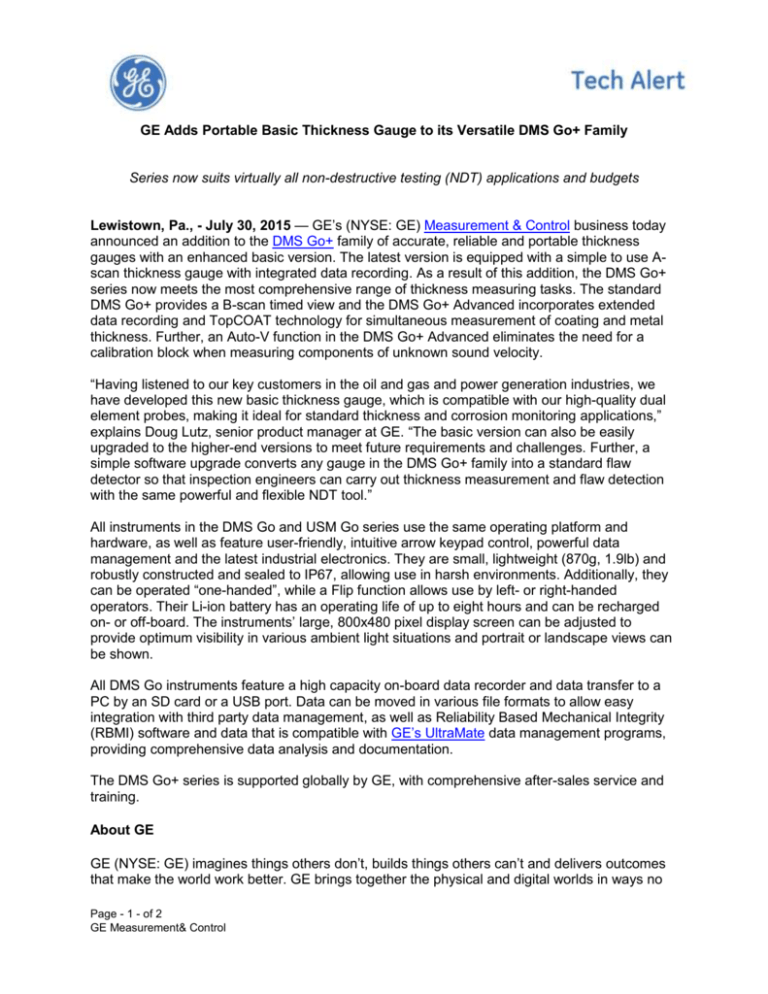

GE Adds Portable Basic Thickness Gauge to its Versatile DMS Go+ Family Series now suits virtually all non-destructive testing (NDT) applications and budgets Lewistown, Pa., - July 30, 2015 — GE’s (NYSE: GE) Measurement & Control business today announced an addition to the DMS Go+ family of accurate, reliable and portable thickness gauges with an enhanced basic version. The latest version is equipped with a simple to use Ascan thickness gauge with integrated data recording. As a result of this addition, the DMS Go+ series now meets the most comprehensive range of thickness measuring tasks. The standard DMS Go+ provides a B-scan timed view and the DMS Go+ Advanced incorporates extended data recording and TopCOAT technology for simultaneous measurement of coating and metal thickness. Further, an Auto-V function in the DMS Go+ Advanced eliminates the need for a calibration block when measuring components of unknown sound velocity. “Having listened to our key customers in the oil and gas and power generation industries, we have developed this new basic thickness gauge, which is compatible with our high-quality dual element probes, making it ideal for standard thickness and corrosion monitoring applications,” explains Doug Lutz, senior product manager at GE. “The basic version can also be easily upgraded to the higher-end versions to meet future requirements and challenges. Further, a simple software upgrade converts any gauge in the DMS Go+ family into a standard flaw detector so that inspection engineers can carry out thickness measurement and flaw detection with the same powerful and flexible NDT tool.” All instruments in the DMS Go and USM Go series use the same operating platform and hardware, as well as feature user-friendly, intuitive arrow keypad control, powerful data management and the latest industrial electronics. They are small, lightweight (870g, 1.9lb) and robustly constructed and sealed to IP67, allowing use in harsh environments. Additionally, they can be operated “one-handed”, while a Flip function allows use by left- or right-handed operators. Their Li-ion battery has an operating life of up to eight hours and can be recharged on- or off-board. The instruments’ large, 800x480 pixel display screen can be adjusted to provide optimum visibility in various ambient light situations and portrait or landscape views can be shown. All DMS Go instruments feature a high capacity on-board data recorder and data transfer to a PC by an SD card or a USB port. Data can be moved in various file formats to allow easy integration with third party data management, as well as Reliability Based Mechanical Integrity (RBMI) software and data that is compatible with GE’s UltraMate data management programs, providing comprehensive data analysis and documentation. The DMS Go+ series is supported globally by GE, with comprehensive after-sales service and training. About GE GE (NYSE: GE) imagines things others don’t, builds things others can’t and delivers outcomes that make the world work better. GE brings together the physical and digital worlds in ways no Page - 1 - of 2 GE Measurement& Control other company can. In its labs and factories and on the ground with customers, GE is inventing the next industrial era to move, power, build and cure the world. www.ge.com About GE Measurement & Control GE Measurement & Control is a leading innovator in advanced software and services; sensorbased measurement; non-destructive testing and inspection; flow and process control; turbine, generator and plant controls; and condition monitoring. Providing for the industrial health of our customers’ most critical assets, we deliver accuracy, productivity, predictive maintenance and safety to a wide range of industries, including oil & gas, power generation, aerospace, metals and transportation. Through our advanced approach to connecting intelligent machines, big data and analytics, we help our customers navigate complex operations, tighter regulations and a growing skills gap; while improving asset and operational performance – ultimately driving better business outcomes. Headquartered in Boston, USA, Measurement & Control has more than 40 facilities in 25 countries and is part of GE Oil & Gas. For further information, visit www.gemeasurement.com. About GE Oil & Gas GE Oil & Gas works on the things that matter in the oil and gas industry. In collaboration with our customers, we push the boundaries of technology to bring energy to the world. From extraction to transportation to end use, we address today's toughest challenges in order to fuel the future. Follow GE Oil & Gas on Twitter @GE_OilandGas. For more information, contact: Chris Janssens T: + 32 34562851 E: chris.janssens@ge.com Page - 2 - of 2 GE Measurement & Control