Presentation - Mid Pacific Testing & Inspection

advertisement

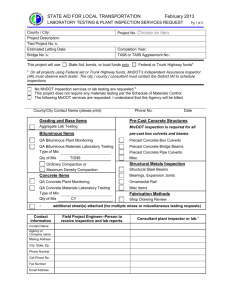

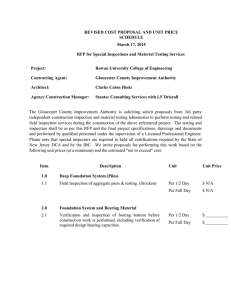

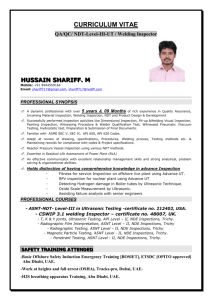

“Assuring Superior Quality” Mid Pacific Testing & Inspection Services, Inc. John Merriman (President) 94-547 Uke`e St., #200 Waipahu, HI 96797 (808 ) 676-2720 www.midpacifictesting.com Who is MPTI? • Established in 1992, Mid Pacific Testing and Inspection (MPTI) is the premiere Quality Control, Quality Assurance, Testing, and Inspection company on the Hawaiian Islands and Western United States. • Registered Professional Engineers and Quality Built Inspections. • Accreditations including: ICC (structural masonry, reinforced concrete, spray applied fireproofing, prestressed concrete, structural steel and welding, soils); ACI (field testing, lab testing); Troxler (hazmat, radiation officer certification, and nuclear density testing); DGI (radioactive materials dangerous goods certification); USACE (construction quality management for contractors); AWS/ASNT, NDT level 3; and AASHTO. If you have a need, more than likely we can fill it. What Makes us Different? • Experience: A combined 75 years in almost every testing, QC, and QA discipline • Focus on Perfection: It’s always our goal to exceed your expectations • Internal Audit Mechanisms: Ensuring superior work and service • Widest Range of Services: Providing your project a one-stop vehicle and one point of contact Services • Quality Assurance: Quality Built (a comprehensive system that provides a “best practices” approach to QA, utilizing a proprietary database that assesses multiple levels of risk throughout a project’s life cycle—from initial plan design compliance to exterior wrap). • Special Inspections/Quality Control Inspections: Reinforcing steel, structural steel welding & bolting, structural masonry, etc. • Quality Control Materials Testing: Concrete, soil, steel, mortar, asphalt, etc. • Specialty Testing: NDT, ultrasound, magnetic particle & dye penetrant, Windsor Probe concrete strength, Schmidt Hammer concrete strength, etc. • Geotechnical Consulting and Engineering Services Risk “Risk comes in two flavors arising out of one failure.” When a system fails there are two things that must be taken into account: • The risk to human life • The cost to repair the failed system In a nutshell, risk is what MPTI helps our clients manage and is ingrained in every aspect of our company. Therefore, utilizing our comprehensive approach to QA, Testing, and Inspection, we help our clients minimize the threat to life safety issues as well as help curtail cost overruns due to expensive reconstruction and repairs. Pricing (Common Items) Laboratory: Field Testing: *Compression Testing: $30/cylinder *Special Inspections: $68/hr *Compression Testing (Flex): $65/beam *Project Manager: $80/hr *Proctor: $200 *Geotechnical Engineer: $155/hr *Sieve (dry): $100 *Concrete Testing & Sampling: $68/hr *Sieve (washed): $320 *Masonry Inspection: $68/hr *CBR: $405 *Welding Inspection: $68/hr *LA Abrasion: $270 *High Strength Bolts Testing: $78/hr *Atterburg Limits: $175 *Asphalt Testing & Sampling: $68/hr *Asphalt Flow & Stability: $150 *Pull Testing: $80/hr *Sand Equivalent: $100 *Epoxy Inspection: $68/hr QA/QC Management: *Is priced on a project-by-project basis. We carefully assess all project documentation in order to ensure our clients that all testing requirements are being met. For a complete listing of prices ask for or download our fee schedule Benefits • Superior Work: Due to our experience, credentials, and continued training • Superior Service: Due to our extensive internal protocols geared specifically for client satisfaction • One Point of Contact: Due to our comprehensive services package •Competitive Pricing: on all services, especially bundled services In short, we will deliver what you need, when you need it. We’re committed to our clients’ long-term success. That’s why at MPTI our goal is to exceed your expectations so that we will be the first and only choice on your next project. “Assuring Superior Quality” We look forward to servicing all your Quality Assurance, Inspection, Geotechnical and Testing needs