Book chapters

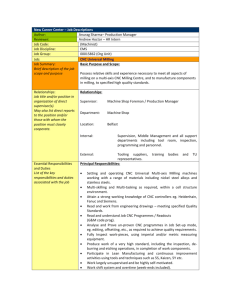

advertisement

Área Científica de Tecnologia Mecânica e Gestão Industrial Equipments of the Industrial Machine Tools Training Laboratory EMCO – CNC milling machine Model: Concept Mill 55 Controllers: Fanuc, Siemens Working area: 190x140x260 mm Maximum table load: 10kg Number of tool stations: 8 Main drive power: 0.75 kW Tool clamping: automatic Speed range: 150-3 500 r.p.m. Speed with high speed spindle: 14 000 r.p.m. 3phase motor in XYZ with resolution: 0.00015 mm Feed rate and rapid traverse in XYZ: 2 m/min EMCO – CNC lathe Model: Concept Turn 55 Controllers: Fanuc, Heidenhain Swing over bed: 130 mm Max. machining diameter: 52 mm Distance between centers: 335 mm Traverse path X/Z: 48/236 mm Rapid traverse: 2 m/min Main drive power: 0.75 kW Speed range: 120-4000 r.p.m. Number of tool stations: 8 DENFORD machine TRIAC – CNC milling Model: CNC Denford Triac 2½ axis Working area: 290x170x235 mm Spindle speed: 150 – 2500 r.p.m. Feed rate: 0 – 1000 mm/min Mechanical resolution: 0.01 mm Circular interpolation: on X and Y planes Equipments of the Industrial Machine Tools Training Laboratory 1 of 3 Área Científica de Tecnologia Mecânica e Gestão Industrial Charmilles / D10 - Isocut Pulse 80 Sinker top EDM machining Power supply: Isopulse 80 – (215 Amp power generator) Table dimensions (w d): 350 230 mm (with 3 “t” slots) Tank dimensions (w d h): 520 x 350 x 200 mm Table longitudinal / cross travel (x / yaxis): 200, 120 mm Quill vertical / Backslide travel (z-axis): 98 / 178 mm Max. platen to table-top / dielectric level: 375 / 178 mm Dielectric / Working capacity: 80 / 30 L Machine / Hydraulic weight, approximately: 318 / 120 kg Max. load: 100 kg Electrical system (volts, phases, amperes): 220/3/60 Machine includes: Systems 3-r rotary head, Super finishing circuit “MicroFin S”, Remote control box Kindly offered by Legrand Eléctrica, S.A. Basic training machines Conventional turning machine Conventional milling machine Signal monitoring and acquisition Piezoelectric transducers are available for the measurement of the three basic physical values; time, displacement and forces in the different metal cutting processes. The DAQ system used for signal acquisition is based in a PC, a DAQ card and other components, such as cables for connection, a terminal block and a signal generator. Equipments of the Industrial Machine Tools Training Laboratory 2 of 3 Área Científica de Tecnologia Mecânica e Gestão Industrial The facility have 8 training stations and multimedia capabilities (16 people) CAD/CAM – training software MasterCAM X2, ESPRIT, WinCAM i-cut 2d Machining simulation: I-Cut 2d industrial cutting technologies Equipments of the Industrial Machine Tools Training Laboratory 3 of 3