The Products and Our Big Company in China

INTRODUCTION TO

TA YANG GROUP

March. 2010

1

Presentation Outline

Mission Statement

Development Milestones

Existing Products and Customers

Our Strengths

2

Mission Statement

3

Our Mission

We offer our customers:

The best quality

Reliable and punctual delivery

Competitive price

Meanwhile, we care for both environmental protection and safety requirements

Based on shipping quantity, Ta Yang is the world’s largest silicone keypad supplier, accounting for 9.9% and 14.6% of the world’s and China’s supply, respectively.

4

Development Milestones

5

Development Milestones

Establishment of Taipei Headquarter, Hong Kong

Sales Office and

Dongguan Ta Yang Silicone Rubber Industrial Co. Ltd

Establishment of Dongguan Silicone

Chemical Material Plant

Establishment of the U.S. Sales Office (TSAC)

1991 1995 1997 2001 2003

Establishment of German Subsidiary (SiTY) and Huzhou Ta Yang Electronic

Technology Company Limited (SAM, Membrane)

Establishment of Dongguan Tay Yang Rubber Plastic Industrial Company

Limited (Silicone Tube)

Set up of P+R Production Line

6

Development Milestones

Establishment of Japan Sales Office (Link – Tayang)

Establishment of Dongguan Tai Yang Rubber Plastic

Industrial Company Limited (P+R)

Establishment of plastic molding division

2007 2008 2004

Completion of new plant in Wuzhou

2005 2006

The Group successfully listed on the HK Main Board

Establishment of brand development

Division - Sipals

7

Offices Worldwide

8

Dongguan Ta Yang Silicone Rubber

Industrial Co., Ltd

Design and manufacturing of Silicone injection molding silicone toolings Printing, spraying, laser marking

Silicone compression molding

9

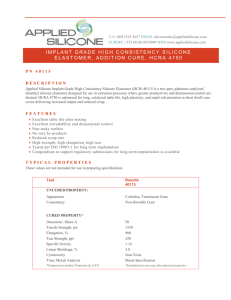

Silicone Chemical Plant

Production of silicone chemicals

HTV/RTV, production of liquid silicone

Production of colored rubber and ink

10

Dongguan Tay Yang Rubber Plastic

Industrial Co., Ltd

Manufacturing of silicone heat sheet

Manufacturing of silicone tube

Manufacturing of silicone cap

11

Huzhou Ta Yang Electronic Technology

Co., Ltd

Silicone compression molding

Silicone injection molding

Design and manufacturing of silicone toolings

Printing, spraying, laser marking

Design and manufacturing of membrane switch layout

12

Dongguan Tai Yang Rubber Plastic

Industrial Co., Ltd

Design and manufacturing of silicone toolings

Silicone injection molding

Silicone compression molding

Printing, spraying, laser marking

Production of PET Emboss, FPC

13

Brand Development Division - Sipals

Make use of the characteristics of silicone to develop branded products: http://www.sipals.com

14

Existing Products and Customers

15

Our Existing Products

Our product categories and major customers:

Keypads for consumer electronic devices: Casio, Philips, SMK,

Funai;

Keypads for mobile phones: Motorola, Nokia;

Keypads for computers: Darfon, Chicony;

Automotive peripherals: Lear, Fujitsu Ten.

Food-grade,Medical-grade daily life products : Le creuset, ABB,

Lifescan, Disney

16

The chart of revenue to major

classified product

17

Products-Consumer Electronic Devices

Keypads for remote controls

18

Products-Consumer Electronic Devices

Keypads for calculators

19

Products-Consumer Electronic Devices

DICTIONARIES

20

Products-Consumer Electronic Devices

Printers

21

Products-Consumer Electronic Devices

Printers

22

Products-Consumer Electronic Devices

Cameras

23

Products-Consumer Electronic Devices

Phone

CCT

24

Products-Consumer Electronic Devices

25

Products- cellphone keypad

26

Products- cellphone keypad

27

Products-Keypads for Computers

28

Products-Automotive Peripherals

29

Products-Automotive Peripherals

30

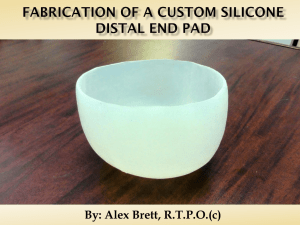

Products-

Food-grade , Medical-grade daily life products

31

Our Strengths

32

Why Choose Ta Yang?

1

20-year professional experience

2

Internal R&D on raw materials & integrated service

6

Sound financial position & improving corporate culture

5

OUR

STRENGTHENS

3

Solid customer base & certification by leading international manufacturers

4

Strong technology partners

Sufficient capacity & quality accreditation

33

20-Year Professional Experience

Manufacturing of moulds

Production of silicone raw materials

Manufacturing of plastic moulds

Strategic investment partners

1991 1992 1994 1996 1998 2000 2002 2004 2006 2007 2008

1

34

Internal R&D on Raw Materials &

Integrated Service

DMC

R&D

Silicone raw materials

Colored rubber & ink

Ta Yang Group

Design Molding Sampling Production

Competitors

Finished products

Ta Yang Group

Competitors

35

2

Sufficient Facilities & Production Capacity

Our Existing Facilities:

452 compression molding machines

40 injection molding machines

41 plastic injection machines

26 automatic spraying lines

28 CNC (includes 4 Mori Seiki Machine Tools)

20 EDM

36

4

Sufficient Facilities & Production Capacity

2008 Capex rose 18% over 2007;

2008 acquired a land parcel in Guangdong for plant expansion;

Completion of Huzhou new plant.

37

4

Pass Through Comprehensive Quality

Accreditation

TS 16949 Funai Philips

ISO9001

ISO 14001

CASIO

Asia Productivity

Specialist

KTS

Nintendo Green

BOSE

38

4

Strong Strategic Partners

Japan’s largest corporation World leading supplier of keypads for mobile phones

Sales Production R&D

5

39

Sound Financial Position

We have sound and healthy financial policies:

Sufficient liquidity, expected to improve continuously;

Low financial leverage, no long-term liabilities;

Our sales grew steadily year-on-year.

6

40

Long-term Gearing at Low Level

0.35

0.3

0.25

0.2

0.15

0.1

0.05

0

29.9%

2006

5.25%

2007

0

2008

0

2009

6

41

Sales Grew Steadily YOY

800

700

600

500

400

300

200

100

409

0

HK$ million

2004

524

580

630

745

621

2005 2006 2007 2008 2009

6

42

Continuous R&D For Upgrading

Our Technology Capacity

We constantly conduct various research and development activities:

26 approved application for patents in total;

14 pending application for patents in total.

6

43

Ta Yang is your reliable, long-term and stable partner

44