Technical Datasheet

advertisement

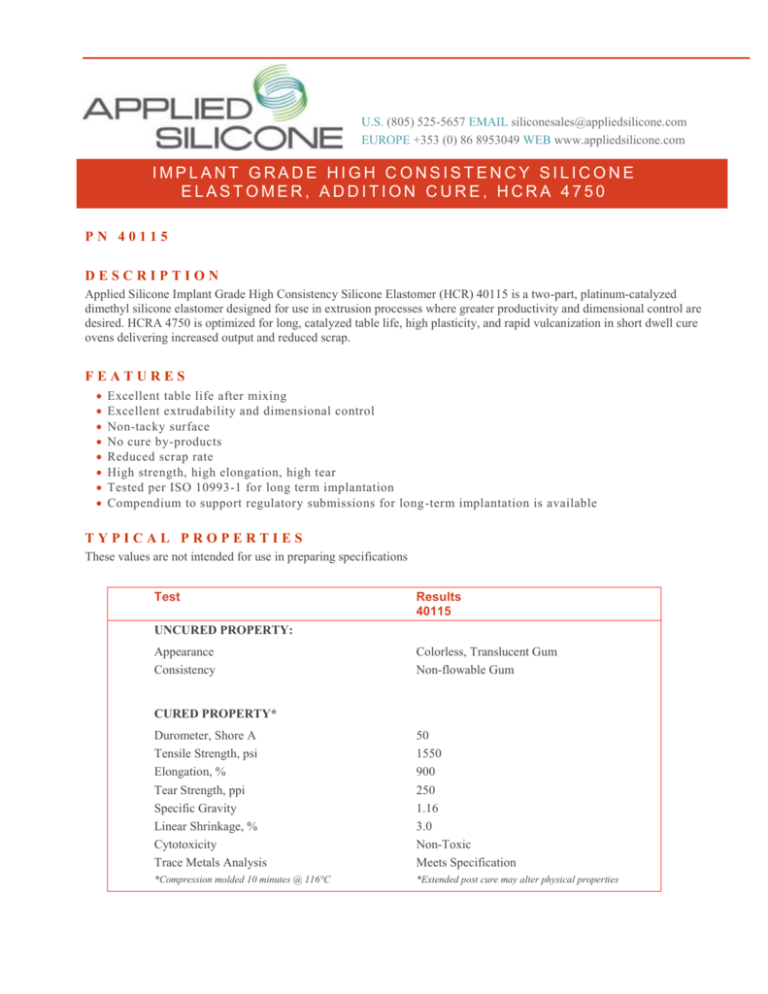

U.S. (805) 525-5657 EMAIL siliconesales@appliedsilicone.com EUROPE +353 (0) 86 8953049 WEB www.appliedsilicone.com IMPLANT GRADE HIGH CONSISTENCY SILICONE ELASTOMER, ADDITION CURE, HCRA 4750 PN 40115 DESCRIPTION Applied Silicone Implant Grade High Consistency Silicone Elastomer (HCR) 40115 is a two-part, platinum-catalyzed dimethyl silicone elastomer designed for use in extrusion processes where greater productivity and dimensional control are desired. HCRA 4750 is optimized for long, catalyzed table life, high plasticity, and rapid vulcanization in short dwell cure ovens delivering increased output and reduced scrap. FEATURES Excellent table life after mixing Excellent extrudability and dimensional control Non-tacky surface No cure by-products Reduced scrap rate High strength, high elongation, high tear Tested per ISO 10993-1 for long term implantation Compendium to support regulatory submissions for long -term implantation is available TYPICAL PROPERTIES These values are not intended for use in preparing specifications Test Results 40115 UNCURED PROPERTY: Appearance Consistency Colorless, Translucent Gum Non-flowable Gum CURED PROPERTY* Durometer, Shore A Tensile Strength, psi Elongation, % Tear Strength, ppi Specific Gravity Linear Shrinkage, % Cytotoxicity Trace Metals Analysis 50 1550 900 250 1.16 3.0 Non-Toxic Meets Specification *Compression molded 10 minutes @ 116°C *Extended post cure may alter physical properties APPLICATIONS Applied Silicone Implant Grade High Consistency Addition Cure HCRA 4750 is mixed in equal parts using standard two-roll mill rubber processing techniques. Care must be taken to work in a clean area with clean equipment. Traces of foreign materials can poison the catalyst and inhibit the cure. For optimum results, freshen both parts separately on a two-roll mill before mixing the components together. Do not allow material temperature to exceed 35°C during the milling. Mixed material should be used within 6-8 hours after mixing to prevent structuring and premature crosslinking. Post cure is recommended to stabilize physical properties. Typical post-cure is 2-4 hours at 175°C. PRECAUTIONS A Material Safety Data Sheet (MSDS) is supplied with each shipment. Accurate measuring and complete mixing are important factors in obtaining consistent results. Contamination by trace amounts of compounds containing sulfur, amines, and organometallic salts can result in an unreliable cure of the material. Organic rubbers and tin catalyzed silicones often contain compounds that can interfere with the cure of this material and should be avoided. Latex gloves should never be used while fabricating or handling products or components utilizing this product. Mix only what is intended for use. Mixed shelf life at room temperature is approximately 6-8 hours. Mixed material can be stored at lower temperatures to extend pot life. To avoid “gels” and imperfections in final product, clean mixing and processing equipment thoroughly of cured residue to avoid becoming incorporated into subsequent batches. Accurate measuring and complete mixing are important factors in obtaining consistent results. Contamination can result in an unreliable cure. Avoid sulfur or amine containing materials that can poison the platinum catalyst. BIOCOMPATIBILITY This material was designed and tested to meet ISO 10993 requirements for long-term implantation. Master Access Files, including formulation, manufacturing methods, testing, and toxicology have been filed with the U.S. Food and Drug Administration. A sample from each manufactured lot is subjected to MEM Tissue Culture testing. A Compendium Summary of physiochemical testing to support regulatory submission for long term implantation is available upon request. TRACE METALS ANALYSIS Trace Metals Analysis Testing meets the following specification criteria of elements set forth in the ISO 14949 STANDARD: Al < 200 ppm Na, Mg, Ca < 100 ppm P, Ti, Fe < 50 ppm Sb, Ge, Mn, Mo, Pb, Sn, Cr, Bi, V, Ag, Co, Ni, Cu, Zr Ba, As, Zn, Se, Cd, Hg, Tl < 10 ppm. This product is neither designed to nor does it comply with the ISO 14949 standard. LOT TESTING Each production lot is certified as having met specifications for durometer, tensile, elongation, tear resistance, specific gravity, trace metals analysis, and Cytotoxicity screening. PACKAGING AND STORAGE Packaging is available in 44-pound (20-kg) kits. This material should be stored under cool and dry conditions. Containers should be sealed to avoid contamination. Material should be stored in original, unopened containers at ambient conditions below 43°C (110°F) to maintain product integrity. Applied silicone does not specify shelf life. Suggested retest date is six months from date of shipment. Retested materials found to conform to quality specifications and user’s retest criteria will be suitable for continued use. DISCLAIMER Applied Silicone Corporation warrants that this product meets applicable descriptions and specifications for a period of six months from shipment. No other warranties, expressed or implied, are intended. This product was designed for sophisticated users. The user must carefully review literature for uses where adverse effects are reported for certain applications of silicone in medical devices. The user of this material must independently determine that any product incorporating this material is safe and effective. The user of this material must thoroughly test any application consistent with industry requirements and/or standards. Applied Silicone Corporation disclaims any expressed or implied warranty against the infringement of any patent. Any suggestion of use by Applied Silicone should not be taken as inducement to infringe on any particular patent. U.S. (805) 525-5657 EMAIL siliconesales@appliedsilicone.com EUROPE +353 (0) 86 8953049 WEB www.appliedsilicone.com