HERE

advertisement

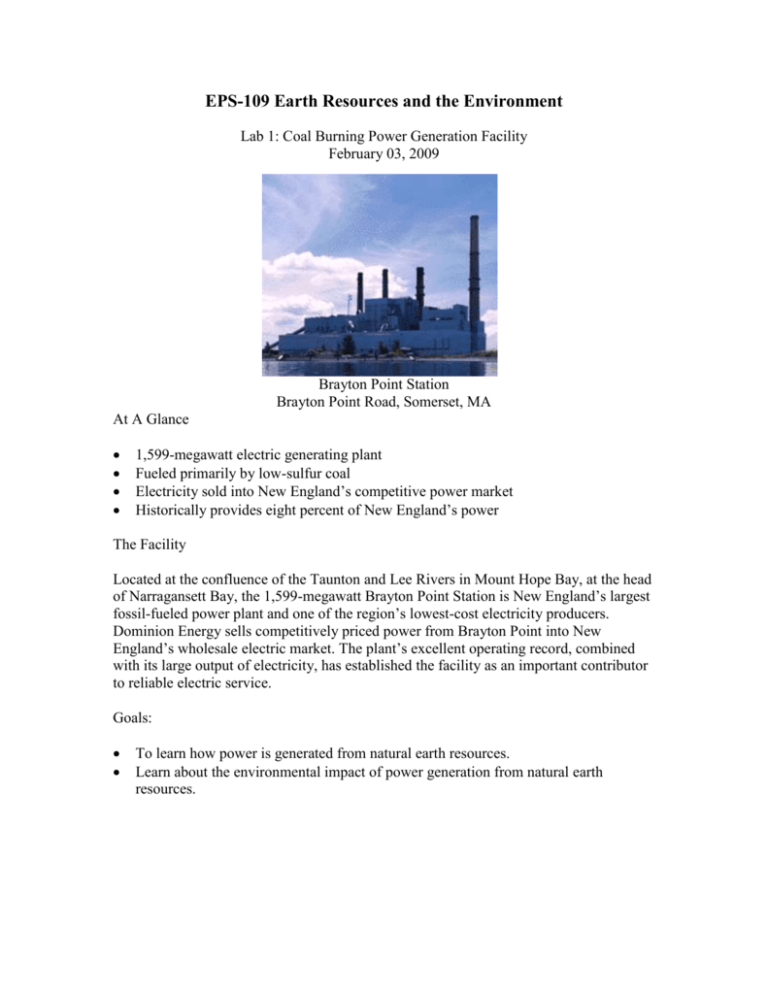

EPS-109 Earth Resources and the Environment Lab 1: Coal Burning Power Generation Facility February 03, 2009 Brayton Point Station Brayton Point Road, Somerset, MA At A Glance 1,599-megawatt electric generating plant Fueled primarily by low-sulfur coal Electricity sold into New England’s competitive power market Historically provides eight percent of New England’s power The Facility Located at the confluence of the Taunton and Lee Rivers in Mount Hope Bay, at the head of Narragansett Bay, the 1,599-megawatt Brayton Point Station is New England’s largest fossil-fueled power plant and one of the region’s lowest-cost electricity producers. Dominion Energy sells competitively priced power from Brayton Point into New England’s wholesale electric market. The plant’s excellent operating record, combined with its large output of electricity, has established the facility as an important contributor to reliable electric service. Goals: To learn how power is generated from natural earth resources. Learn about the environmental impact of power generation from natural earth resources. The production of electricity basically involves heating water to make steam. The steam spins a turbine that drives a generator to produce electricity. This cycle is the same whether a plant gets heat from nuclear energy, or by burning gas, oil or coal. In some parts of the region, 100 percent of electricity is generated by coal. Coal-based electricity is a reliable and low-cost energy source. Coal Storage and Handling Coal is transported to the power plant by truck or rail. It is then stockpiled or put in silos. A coal handling system moves the coal from the storage area into the plant. Coal Pulverizers The coal is taken from the conveyors and crushed in pulverizers into a powder. The Boiler Numerous burners are located inside the boiler. The pulverized coal is blown into the boiler where it ignites spontaneously at temperatures of up to 3,000 degrees Fahrenheit. The purpose of the boiler is to turn water into steam. Air is drawn into the plant by huge force-draft fans. As the air enters the plant it passes through a heat exchanger that transfers heat from outgoing exhaust gases to the incoming air. Approximately half of the heated air is channeled through the coal pulverizers to dry and blow the coal into the boiler. The other half goes directly to the boiler for combustion. The hot gases resulting from combustion are drawn through the boiler and the heat exchanger (where incoming air is warmed). The exhaust gases then travel to the scrubber. The Scrubber In the scrubber, the exhaust gases from the boiler are sprayed with absorbents such as limestone or lime-water to remove sulfur dioxide to comply with environmental regulations. BagHouse The exhaust gases then move from the scrubber to the fabric filter baghouse. The filter process, which operates on the same principle as a vacuum cleaner, removes 99.9% of the ash and other particulates. The baghouse in this schematic contains more than 8,000 bags that are 35 feet tall and one foot in diameter. The Stack Induced-draft fans, located near the stack, pull the exhaust gases through the environmental equipment and send it up the stack. On cold days, the white plume from the stack of this type of plant is actually just water vapor condensing. On hot days, even though the plant is operating, stack emissions are clear. Water Sources and Storage The power plant needs water to create steam. Depending on the location of the power generating facility, water is pumped through underground pipes to storage ponds from a variety of sources, such as reservoirs, lakes or rivers. Water Treatment The water then flows through a treatment process to purify it for steam generation. Water in the boiler cannot contain minerals or particles that might collect as deposits inside the boiler tubes or damage the turbine blades. Creating Steam As water (light gray) enters the boiler, it is preheated by hot gases leaving the boiler. The water then enters the steam drum where it is pressurized and turns to steam (light line). That steam is "superheated" (dark gray line) and sent to the turbines. Water that is not converted to steam goes down to the bottom of the boiler and is pumped through the walls of the boiler and directed to the steam drum. Turbines Steam heated in the boiler first enters the high-pressure turbine at about 2,400 pounds per square inch and 1,005 degrees Fahrenheit. As it passes through the high-pressure turbine, the steam cools to about 600 degrees Fahrenheit and flows back to the boiler where it is reheated to 1,005 degrees. The reheated steam passes through the intermediate and low pressure stages of the turbine and exhausts to the condenser. This pressurized steam causes the blades of the turbine to rotate similar to the action of wind on a windmill. A continuous shaft connects the turbine to the generator. Cooling the Water for Reuse The condenser consists of several thousand cold water pipes underneath and parallel to the low-pressure turbines. As steam contacts these pipes, it condenses to water, creating a vacuum that draws steam through the turbine. The water is pumped back into the boiler, repeating the cycle. Cold water traveling through the condenser picks up heat from the steam as it condenses to water. The steam and cooling water do not come into direct contact during the heat-exchange process. The hot water is pumped from the condenser to the top of the cooling tower. It cascades to the bottom against cool air being forced up by two dozen 22-foot diameter fans at the base of the cooling tower. Cooling takes place by evaporating thousands of gallons of water per minute from each tower. Not all plants use cooling towers; some pump water from a lake or river and return it. Cooled water returns to the condenser, repeating the cycle. Electricity is Made The pressurized steam from the boiler causes the blades of the turbine to rotate. A continuous shaft connects the turbine to the generator. The generator consists of a rotor and a stator. The rotor spins inside the stator at 3,600 revolutions per minute, setting electrons into motion and creating a flow of electricity. As the electricity exits the generator at approximately 22,000 volts, it passes through the generator step-up transformer where voltage is increased to 345,000 volts. Power then flows through a switchyard and along a network of high voltage transmission lines to delivery points where the voltage is reduced several times for use in homes, farms and businesses. Questions to think about: 1. Why was Brayton Point selected as the site of this power station? 2. What methods are used to minimize the release of SO2 and NOx to the atmosphere? 3. Approximately what fractions of the total S, N, As, and Hg released by the combustion of fossil fuel are incorporated into concrete, disposed of as solid waste, and released to the atmosphere respectively? 4. What changes in operations are made to meet large increases in the demand for electric power? Do these changes affect the characteristics of the produced fly ash?