Maree SAIMM 2011 09 15 C

advertisement

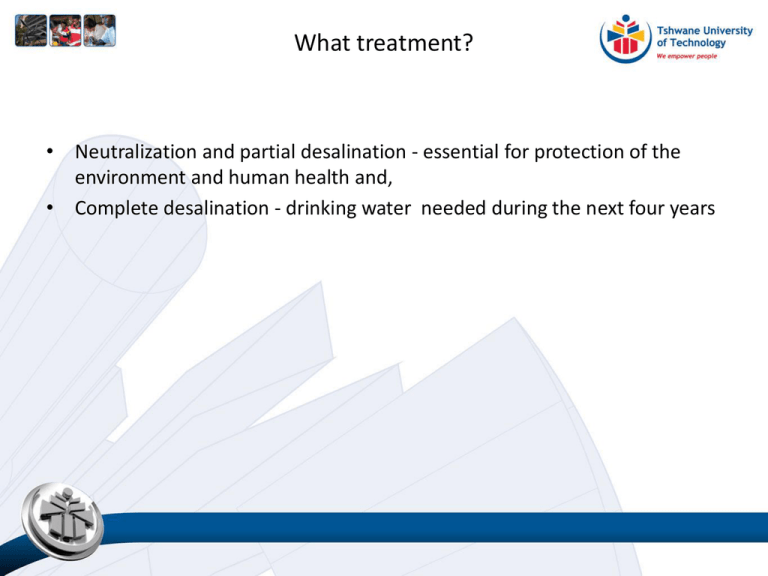

What treatment? • Neutralization and partial desalination - essential for protection of the environment and human health and, • Complete desalination - drinking water needed during the next four years Limestone handling and dosing system Full-scale neutralization plants • Iluka Resources, Hamilton • Namakwa Sands, Lutzville Fe(II)-removal with sequence batch operation Parameter Western Basin Flow (Ml/d) Chemical cost (R/m3) Chemical cost (R/a) Central Basin Flow (Ml/d) Chemical cost (R/m3) Chemical cost (R/a) Total Flow (Ml/d) Chemical cost (R/m3) Chemical cost (R/m3) Chemical cost (R/a) Limestone /lime Only lime 33 33 1.02 3.02 36 300 000 12 300 000 56 56 1.07 3.19 65 200 000 21 900 000 89 89 1.05 3.12 101 500 000 34 200 000 Treatment at Grootvlei water (108 Ml/d) • Grootvlei Mine where contains 100 mg/l iron(II) and 350 mg/l alkalinity. Currently this water is treated at a cost of R3.7 million/month, using lime and oxygen. • 100mg/l need to be oxidised in a more cost-effective way. Desalination • Need 400 Ml/d by 2014 in Gauteng • Coal mining sector already produce 35 Ml/d drinking water from mine water in Mpumalanga CSIR ABC Desalination process (Alkali-Barium-Calcium) • Lime and/or CaS pre-treatment • Barium treatment for SO4 removal • Sludge processing CaCO3 Ca(HS)2 Ca(OH)2 CO2 AMD H2O H2O Coal CaSO4 Mg(OH)2 MS BaCO3 Sludge processing stage CaCO3 Ca(HS)2 Ca(OH)2 CO2 BaSO4 CaCO3 Western Utilities Corporation pilot plant to evaluate ABC process TUT MBO process (magnesium-barium-oxide) • Metal removal with Mg(OH)2 • SO4 and Mg removal with Ba(OH)2 • Sludge processing Mg(OH)2 Ba(OH)2 CO2 AMD Treated H 2O BaSO4 Mg(OH)2 H 2O Fe(OH)3 Al(OH)3 MnO2 H 2O Coal Ash S Ba(OH)2(aq) Mg(OH)2 CaCO3 Soshanguve pilot plant for freeze desalination Ice filter Heat exchangers Refrigeration unit Ice production Official launch – 25 October 2011 at 13:00 as Soshanguve Campus of TUT