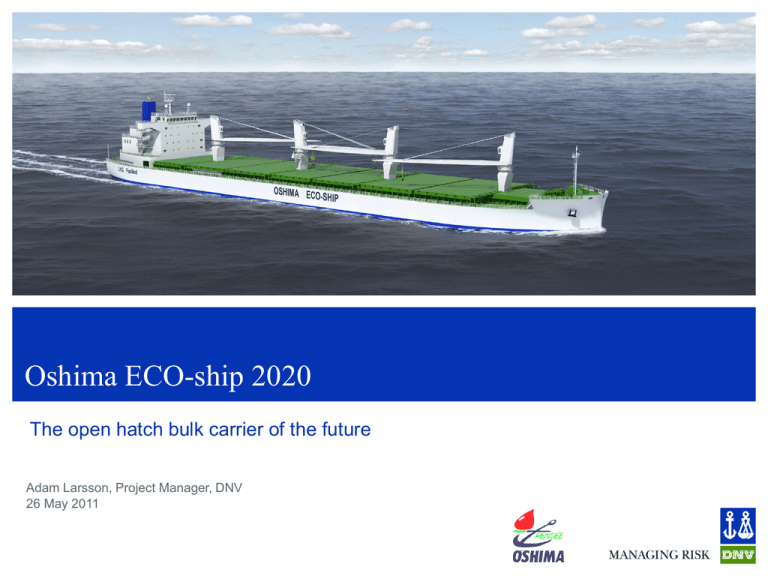

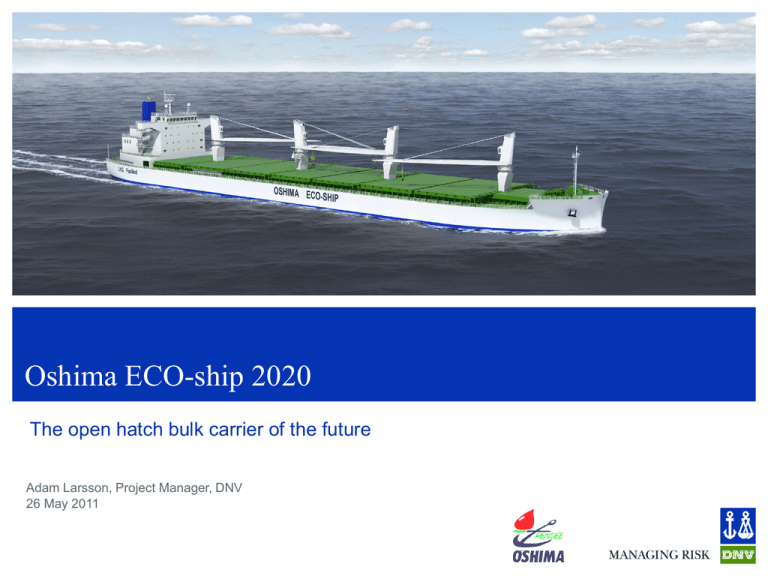

Oshima ECO-ship 2020

The open hatch bulk carrier of the future

Adam Larsson, Project Manager, DNV

26 May 2011

Oshima ECO-ship 2020 - Objectives

Environmental friendly

Energy efficient

Cost-effective

Flexible operations

Oshima ECO-Ship 2020

26 May 2011

© Det Norske Veritas AS. All rights reserved.

2

Design basis

Market and logistics study

- Basis for selection of main particulars and technical solutions

Operational profiles and trading routes identified

- Basis for fuel consumption calculations

Open Hatch Bulk

Carrier segment:

-

Many port calls

Pulp trades

Few ballast voyages

Average load level 77%

Oshima ECO-Ship 2020

26 May 2011

© Det Norske Veritas AS. All rights reserved.

3

Concept overview

Main features:

-

LNG fuelled – LNG as only fuel on board

Wide air lubricated twin skeg hull

Flexible propulsion and power generation systems

Waste heat recovery

Composite hatch covers

Large capacity electric deck cranes

Oshima ECO-Ship 2020

26 May 2011

© Det Norske Veritas AS. All rights reserved.

4

Hull

Optimised to fit operational profile

Wide twin skeg hull

Seaworthy Bow

Air lubrication

Flipper fins

Reduced fuel consumption

Low total resistance

- Calm water

- Waves

High propulsive efficiency

Oshima ECO-Ship 2020

26 May 2011

© Det Norske Veritas AS. All rights reserved.

5

LNG fuelled

LNG only, no fuel oil for propulsion or power generation

Fully compliant with existing and future expected emission requirements

-

ECA and EU port regulations

IMO Tier III regulations

No SOx and particulate emissions

Significant reductions of CO2

Clean working environment

No risk for accidental oil pollution

LNG tank location in aftship

4 C-type pressurised tanks

Total tank capacity 3,000 m3

Oshima ECO-Ship 2020

26 May 2011

© Det Norske Veritas AS. All rights reserved.

6

Machinery and propulsion systems by Rolls-Royce Marine

2 lean-burn 4-stroke medium speed gas engines, 2 x 4,000 kW

1 auxiliary gas engine, 1 x 1,400 kW

Hybrid Shaft Generators, PTI/PTO mode

Frequency converters

Waste heat recovery

PROMAS, integrated propeller and rudder

Low fuel consumption

High energy efficiency

Twin screw redundancy

Flexible propulsion and power generation

Excellent manoeuvrability

Oshima ECO-Ship 2020

26 May 2011

© Det Norske Veritas AS. All rights reserved.

7

Operational solutions

All-electric deck machinery

Composite materials

Large capacity electric jib cranes, 4 x 75t

Hatch covers

High cargo handling efficiency

Reduced energy consumption

Significant weight reduction

Easy handling by deck crane

(no hydraulic systems)

Less maintenance

Oshima ECO-Ship 2020

26 May 2011

© Det Norske Veritas AS. All rights reserved.

8

The ECO-Ship is commercially viable

Compared to a conventional Oshima

OHBC, the ECO-ship requires an

additional investment of about 23

MUSD

This extra investment is expected to

be earned back within 10 years

The ECO-ship improves the

expected net present value before

tax by 38 MUSD over a lifetime of 25

years

Oshima ECO-Ship 2020

26 May 2011

© Det Norske Veritas AS. All rights reserved.

9

Concluding remarks

Environmental friendly

-

-

No emissions of SOx or particulates

90% NOx reductions

CO2 reductions of at least 50%

compared to base case

Energy efficient

-

Cost-effective

Flexible operations

-

LNG fuelled

Waste heat recovery

Electric deck machinery

Oshima ECO-Ship 2020

26 May 2011

© Det Norske Veritas AS. All rights reserved.

10 years pay-back time

Improved lifetime net present value

of 38 MUSD

10

Machinery and propulsion system

Large capacity deck cranes

Composite hatch covers

Safeguarding life, property

and the environment

www.dnv.com

Oshima ECO-Ship 2020

26 May 2011

© Det Norske Veritas AS. All rights reserved.

11