ISO 15189:2012

ISO 15189:2012

Medical laboratories-

Requirements for

Quality and competence

นางสุขใจ ผลอ าไพสถิตย ์

30 กรกฎาคม 2557

•

เตรียมความพร้อมในการขอร ับรอง

ISO 15189:2012

ปี 2558

Reference: Gap analysis of ISO 15189:2012 & ver. 2007 (NATA); issued 2013

Summary of changes

• Improved layout & listing of subclauses

• More logical ordering of subclauses

• Two new normative section (5.9 and 5.10)

-5.9 Release of results ( 5.8 split into 5.8 & 5.9)

-5.10 Lab Information Management (New section)

• Additional detail, no change of intent to the requirements

Summary of changes (2)

• Title : Medical laboratories-Requirements for quality and competence

• Definitions

- 19 (2007) and 27 (2012) definitions

- (7) removed: accuracy to measurement , uncertainty etc.

- Additional 15 definitions: alert interval, nonconformity, process etc.

ISO 15189: 2003, 2007, 2012

• ISO 15189:2007

• ข้อก าหนด 4.1-4.15

• ข้อก าหนด 5.1-5.8

•

ISO 15189:2012

• ข้อก าหนด 4.1-4.15

• ข้อก าหนด 5.1-5.10

4.1 Organization and management

Organization and management responsibility

4.1

4.1.1.2 amend

4.1.1.3

Editorial

4.1.1.4 amend

4.1.2.2 new

4.1.2.4 new

Org. and management responsibility

Legal entity can be held legally responsible for its activities

(เรียบเรียงใหม่)

-

Specific responsibilities of lab director/delegates and management responsibilities (ensure the implement of quality policy)

-Meet the needs of lab patients and users

-Measurable quality objective

4.1

4.1.2.5new

4.1.2.6 new

Org and management responsibility

Responsibility ,authorities, interrelationships defined, documented, communicated

Effective communication both within lab and with lab stakeholders

4.1.2.7 amend Responsibilities of QM include the promotion of awareness of users’ needs and requirements throughout the lab

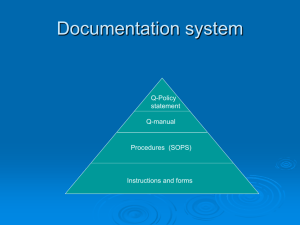

4.2 Quality Management System

4.2

4.2 sig.editorial

4.2.1

4.2.2.1

QMS

4.2.1 General requirements

4.2.2 Document requirements

4.2.2.1 General

4.2.2.2 Quality manual

-Lab establish, document, implement and maintain QMS and continually improve its effectiveness

- Integrate all processes to fulfil its quality policy and objective

QMS documentation: Quality policy & objective/QM/Procedure/record

Copies of regulation, Stds, normative docs

4.2

4.2.2.2

QMS

QM

-Quality policy/ make ref to it

-Description of scope of QMS

-Org and management structure of lab and its place in parent org

-Role and responsibility of lab management/lab director/ quality manager

-Structure of doc & relationships of doc in QMS

-Documented policy and reference to the both activities

All staff access to the use and be instructed on the use of QM and referenced docs

4.3 Document control

4.3

4.2.2.2 amended

Doc con a. all documents/computerized sys. reviewed & approved before issue b. Page 1 of 5 c. Master index/ master list: current editions d. Amendment by hand; marked, initialed, dated and revised issued within specified time

4.4 Review of contracts

Service agreement

4.4

Service agreements

4.4.1 sig editorial c. Lab personnel have the skills and expertise for the examination

4.5 Examination by referral laboratories

4.5

Examination by referral laboratories

4.5.1 amended

4.5.2 amended

Selecting and evaluating referral lab and consultants for complex testing in any discipline not just histopathology, cytology and related disciplines

The report indicate which examinations were performed by a referral lab or consultant

4.6 External services and supplies

4.6

4.6 Sig editorial

External services and supplies

-

Procedure for selecting and purchasing of external service, equipment, reagents, and consumable supplies

-Select and approve suppliers, criteria for

Selection

-List of selected and approved suppliers maintained

4.7 Advisory services

4.8 Resolution of complaints

4.9 Identification and control of nonconformities

4.9

4.9 amended

Identification and control of nonconformities

-The procedure ensure that the immediate actions to be taken are defined

-when NC recur in pre-exam, exam, post

–Exam, corrective action determined

4.10 Corrective action

4.10

4.10 amended

Corrective action

-

Immediate action

-Corrective action to remove the root cause of the problem

4.11 preventive action

4.11

4.11 editorial

Preventive action

review lab data& information if potential NC exist

-determine root cause of potential NC

-Involve analysis of data, trend, risk, external quality assessment.

4.12 Continual Improvement

4.12

4.12 new/amended

Continual Improvement

-Improvement activities are to be directed at areas of highest priority based on risk Assessment/NC

-lab management communicate to staff improvement plan and goal

4.13 Control of records

4.13

4.13 new/amended

/ editorial

Control of records

-Record created concurrently with performance of each activity affecting the quality of examination

-Date and time of amendments capture along with identity of personnel making the amendment

-The length of time that records are retain may vary, reported results as long as medically relevant or by regulation

-The records : minute of meetings, staff qualification

Evaluation and audits

4.14

4.14.1

Evaluation and audits

General

Plan and implement the evaluation and IA processes

( demonstrate examinations &supporting processes are being conducted, to conformity to

QMS, continually improve the effectiveness of

QMS)

Result of evaluation and improvement to MR

4.14.2

(5.4.9)

Periodic review of requests, suitability of procedures, sample requirements

-ทบทวนวิธีวิเคราะห์เป็นระยะๆตามก าหนดเวลา

-ทบทวนปริมาณ, preservative, collect device

4.14 IA

4.14.3

4.14.4

4.14.5

Evaluation and audits

Assessment of user feedback

Staff suggestion

ส่งเสริมให ้ staff เสนอการปรับปรุงในการให ้บริการ (lab service) ประเมินข ้อเสนอและน าไปปฏิบัติอย่างเหมาะสม

และตอบกลับผู ้เสนอ

Internal audit

-pre- exam, exam, post-exam, all activities in the

QMS

ต ้องแก ้ไขทันที (correction) และ corrective action

ต ้องแก ้ไขในระยะเวลาที่ไม่ล่าช ้าเกินไป เพื่อรีบจัดการ

แก ้ไขที่สาเหตุ

4.14 IA

4.14.6

Evaluation and audits

Risk management

ประเมินผลกระทบของขั้นตอนการวิเคราะห์และ

ความผิดพลาดที่อาจเกิดขึ้น ต่อผลการวิเคราะห์

ปรับขั้นตอนการวิเคราะห์เพื่อลดความเสี่ยงที่พบ

และจัดการแก ้ไขและบันทึกเก็บไว ้

4.14

4.14.7

(5.8.2)

Evaluation and audits

Quality indicator

มีตัวชี้วัดในการตรวจสอบ (monitor) และประเมินการ

ปฏิบัติงาน กระบวนการวิเคราะห์เช่นจ านวนตยที่ไม่

เหมาะสม จ านวนรายงานผลที่ต ้องแก ้ไข

การจัดเก็บตัวชี้วัด จัดท าเป็นแผน / โครงการ (Plan): objective, methodology, Interpretation, limits, action plan, duration of measurement

ทบทวนตัวชี้วัดตามระยะเวลาที่ก าหนด

ตัวชี้วัดด ้าน non- exam procedure ; completeness of equipment and personal record , effective of doc control system

ตัวชี้วัดด ้าน Exam: TAT

4.14 IA

4.14.8

Evaluation and audits

Reviews by external organizations

เมื่อพบ NC

-Immediate action

-Corrective action, preventive action

4.15 Management review

4.15

4.15.2

Management review

Review input : results of evaluations

User feedback

Staff suggestion

Risk assessment

Use of quality indicator

Recommendation for improvement etc

-Review activities

Analyse the input for causes of NC, trend and pattern that indicate process problems

assessing the opportunities for improvement and changes ; quality policy and quality objectives

4 .15

4.15.2

Management review

Review output

MR recorded with decisions made and action taken related to improvement of the effectiveness of QMS of its processes, services to users, resource needs