Capability Test For a good analysis capability is necessary to follow

advertisement

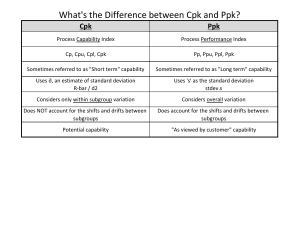

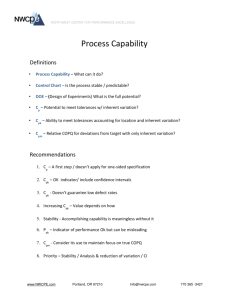

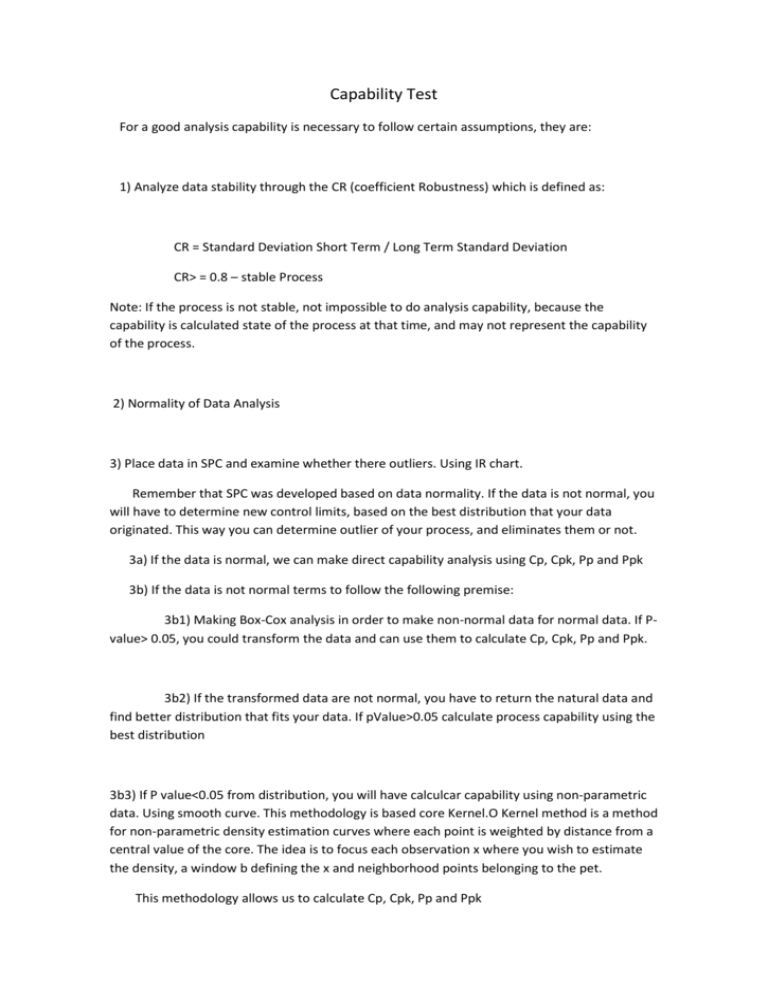

Capability Test For a good analysis capability is necessary to follow certain assumptions, they are: 1) Analyze data stability through the CR (coefficient Robustness) which is defined as: CR = Standard Deviation Short Term / Long Term Standard Deviation CR> = 0.8 – stable Process Note: If the process is not stable, not impossible to do analysis capability, because the capability is calculated state of the process at that time, and may not represent the capability of the process. 2) Normality of Data Analysis 3) Place data in SPC and examine whether there outliers. Using IR chart. Remember that SPC was developed based on data normality. If the data is not normal, you will have to determine new control limits, based on the best distribution that your data originated. This way you can determine outlier of your process, and eliminates them or not. 3a) If the data is normal, we can make direct capability analysis using Cp, Cpk, Pp and Ppk 3b) If the data is not normal terms to follow the following premise: 3b1) Making Box-Cox analysis in order to make non-normal data for normal data. If Pvalue> 0.05, you could transform the data and can use them to calculate Cp, Cpk, Pp and Ppk. 3b2) If the transformed data are not normal, you have to return the natural data and find better distribution that fits your data. If pValue>0.05 calculate process capability using the best distribution 3b3) If P value<0.05 from distribution, you will have calculcar capability using non-parametric data. Using smooth curve. This methodology is based core Kernel.O Kernel method is a method for non-parametric density estimation curves where each point is weighted by distance from a central value of the core. The idea is to focus each observation x where you wish to estimate the density, a window b defining the x and neighborhood points belonging to the pet. This methodology allows us to calculate Cp, Cpk, Pp and Ppk Remember that Cp process capability looking future. Cpk is centralization of the process looking future. Pp is performace of the process looking for today, your current data and Ppk process is centralizing data looking today or current data. - Below show PFM – Capability Analyse… PROCESS FLOW MAP - CAPABILITY ANALYSE START 1 DATA COLLECT STABILITY TEST CR>=0,8 NORMALITY TEST NO NORMAL CURVE ? MAKE BOX-COX TRANSFORMATION YES PUT DATA SPC CHART (IR) AVAILABLE OUTILIER´S SPECIAL CAUSE ? DATA ANALYSE REMOVE DATA ? YES NO NO YES SIM MAKE NORMALITY TEST NORMAL CURVE ? NO MAKE BOX-COX TRANSFORMATION NORMAL CURVE? FIND BEST TRANSFORMATION FOR DATA NO YES YES NO CALCULATE Cp, CpK,SIM Pp, Ppk, DPMO AND SIGMA LEVEL PVALUE>=0,05 ? YES NO PROCESS CAPABLE? YES END USING BRAINSTORM, ISHIKAWA, X.Y MATRIX , FIVE WHY, AND 5W2H IMPROVE PROCESS 1 MAKE ANALYSE NO PARAMETRIC DATA Smooth Curve