IS365SAPProductionProcess

advertisement

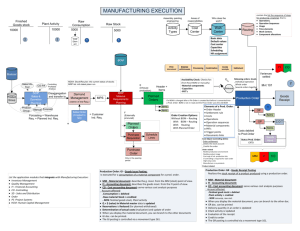

The Production Process Introduction Production is both a SCM function and an accounting function Simply put, the process involves turning raw materials into finished goods YOUR BOOK DOES A VERY GOOD JOB WITH THIS TOPIC Production Steps Types of Production (1) Discrete manufacturing The result is an individual unit (or many of them) such as a bicycle The finished good “could” be decomposed back into its raw materials Production lines are set up and torn down to make batches of different materials Hewlett Packard Types of Production (2) Repetitive manufacturing Similar to discrete manufacturing The same finished good is produced over time on the same production line The production line is not changed to make different products Used when production lines are very expensive Intel (Chips) Seagate (Disks) Types of Production (3) Process manufacturing Products are made by means of a recipe Categories Continuous (flow) Batch Gasoline Soda and beer We will not work with these Means of Production Triggers cause production runs to be executed Make to stock Make a batch resulting from MRP or other production trigger Make to order Make a unit(s) as a result of a customer order Dell Production Master Data Bill of materials (BOM) contains components that make up a product or assembly Work centers are locations within a plant where production operations are performed Product routings list the activities involved in producing the product defined by the BOM Product groups are used in planning to aggregate planning activities Bill of Materials (Overview) In general, the components needed to produce semi-finished goods or finished goods In the case of process manufacturing, we call a BOM a formula or recipe We will focus on discrete manufacturing Bill of Materials (SAP) SAP implements BOM as a flat structure Hierarchical BOMs can be created using “component” materials (assemblies) The BOM structure should mimic the manufacturing process See the BOMs in Figure 6-4 on page 184 Bill of Materials (Organization) A BOM applies to a “plant” Different plants might make the same finished good using a different BOM A material can have “alternate” BOMs These might be used for different processes having different lot sizes This is more common in process manufacturing We will not work with alternate BOMS Bill of Materials (Organization) Header section Applicable to the finished good List the plant and BOM number The purpose of the BOM (production, engineering, plant maintenance) Base quantity Minimum and maximum lot size Bill of Materials (Organization) BOM Header BOM Usage (+must, .can, -cannot) Bill of Materials (Organization) Items section The raw materials that go into making the finished good Item type Item Item quantity Bill of Materials (Organization) Bill of Materials (Organization) Bill of Material (Item Categories) Inventory is maintained for stock items (L) Inventory is not maintained for non-stock items (N) Variable sized items (R) are available in different dimensions (quantities) Lumber, for example Bill of Material (Item Categories) Document items (D) represent applicable documentation Manuals, for example Class Items (K) are used in variant (configurable) BOMs Different paint colors perhaps BOM Complexity A 747-400 contains 6.5 million parts Countless assemblies The process requires that many parts are inspected before, during, and after installation Bill of Materials (Navigation) Logistics / Production / Master Data / Bills of Material / Bill of Material / Material BOM CS01 – Create CS02 – Change CS03 – Display Work Center (Introduction) “A resource used to produce a material” It can be a machine, a group of machines, or an entire production line It can be a person or group of people (labor) Work Center (Introduction) Work centers can be arranged hierarchically Work centers have capacities They can produce finite outputs given a set of constraints People work 8 hours a day Machines can perform at some speed Work Center (Global Bike) We have work centers for Bike Assembly Inspection Packaging Work Center Hiererchy Work Centers (SAP) A work center belongs to a plant Work centers have a category that describes the work center Machine / Labor / Production line / Etc.. A work center has a standard value key These are activities that consume time Setup Processing Teardown Work Center Categories Work Center Standard Value Key Execution time and costs are calculated in operations using formulas and standard values Work Centers (Control Keys) Control keys define how an operation is processed based on a set of indicators Scheduling – Enables scheduling on the operation in Quality Management and Production Planning Capacity – Enables capacity planning for the work center Indicators to print time tickets and shop papers Work Centers (Control Keys) Control keys are managed in the IMG Work Centers (SAP) Default values containing wage data can be associated with a work center Note that work centers are associated with cost centers. This is how we allocate production costs See Figure 6-7 page 189 Work Center (Navigation) Logistics / Production / Master Data / Work Centers CR01 – Create CR02 – Change CR03 – Display Work Center (Basic Data) Every work center belongs to a work center category (i.e. Labor) And has a standard value key for a dimension (time in this case) Work Center (Basic Data) The Assembly work center has execution time for setup, machine, and labor Work Center (Scheduling) A work center has a capacity category usually to indicate machine or labor capacity Formulas that calculate the setup, processing, and teardown time for the work center Formulas are a subject in themselves Work Center (Scheduling) Formula use “special” variables to calculate the dimensional value (time) Work Center (Costing) Here, we allocate the costs of the work center to a cost center The cost center must exist and belong to the plant’s controlling area All costs from a work center must be applied to the same cost center Costs are allocated based on a formula key Same as scheduling Work Center (Costing) Work Center Costing Routings (Introduction) These are the detailed operations performed by (at) one or more work centers to produce a finished good Routing Sequences Have Think of the detailed operations required for an assembly line to run Operations that get performed Material(s) required Routings apply to a material and plant Routing (Header) Task / Usage (production / plant maintenance / …) Validity information Inspection (QA / QC) information Routing (Sequences) Routing sequences Using sequences, you can create standard and parallel sequences Remember a parallel fork Sequences are performed “in-order” Alternate sequences might be performed in place of standard sequences Different steps based on the number of workers Routing (Sequences) We have only one routing sequence Routing (Operations) The tasks we perform to manufacture Data The time it takes to perform the task How many items are processed per interval of time Setup, labor, machine Steps in a routing operation are performed in a work center Production Routing for (DXTR1000) (Operations) Production Routing (Materials) The materials needed to produce the good This information comes from the BOM Production Routing for (DXTR1000) (Materials) Routing (Navigation Path) Logistics / Production / Master Data / Routings / Routings / Standard Routings CA01 Create / CA02 Change / CA03 Display Production Capacity Production has a capacity that relies on A factory calendar describing workdays and holidays A capacity for people and machines Some number of shifts that workers work Look at page 195 in your text. Production Capacity (Factory Calendar) Multiple calendars describe Public holidays and the current The calendar used by the factory The assignment of a calendar to a plant Production Capacity (Factory Calendar) Holiday calendar Maintaining Capacities Each work center in a plant has a capacity A capacity name (SHIFT for example) A capacity category (machine or person for example) Maintaining Capacities Capacity header describes available capacity Maintaining Capacities Global Bike runs 1 shift with 1 hours of breaks per shift The Production Process (Overview) Request production Authorize production Release production order Goods issue to production order Actual production Production confirmation Goods receipt into inventory Request Production Production is typically requested because of a trigger A customer order (make-to-order) An MRP Manual creation In the end, a production order gets generated Authorize Production This is the actual commitment to produce Production (machine / people) time is allocated for specific dates Authorization might be created from planned or unplanned orders Authorize Production (SAP) Production might be authorized because of Planned production / a sales order / for a material (finished good) We get preliminary estimates of cost Logistics / Production / Shop Floor Control / Order / create C001 Production Order (Illustration) Release Production Order This is where the authorized order is actually released to production Production starts the manufacturing process at a given date and time RTP might happen manually or automatically Shop papers are generated Goods Issue Raw materials are removed from storage triggered by the production order release Material staging takes place Backflushing Goods Issue (2) Raw material inventory is updated Inventory accounts are updated Material costs are added to the production order See the GL transactions on page 208 Actual Production We make the material and record production times Production Confirmation Accounting finalizes the production run Production costs are recorded Here the produced goods are transferred from production to goods storage Goods Receipt Here, the goods are released into inventory Inventory Held for a particular customer Held for QA or other reason Introduction to Planning