the Presentation

advertisement

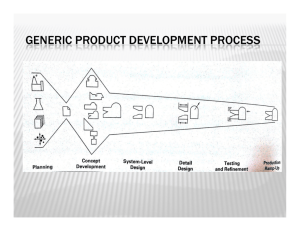

FROM SKETCH TO A PRODUCT TA R I Q A L- M U R B AT I JM COOLERS FA C T O R Y 1- SKETCH, LIST FEATURES AND FUNCTIONS Features define the physical feelings and appearance, while functions describe capabilities. In other words, what does your idea looks like, and what it can do ? 2- PROTOTYPE FUNCTIONALITY Find items at home, hardware stores which have one or more of the functions of the idea. Carefully separate the needed parts and pieces from those items to use in your prototype. This step helps identify the type of materials you may be used during manufacturing 3- ASSEMBLY REQUIRED Use hot glue, staples, tape or anything that get the prototype to be assembled. This step focuses to help functionality. 4- PROTOTYPE FORM The goal of this step is to shape and form the prototype, based on the initial sketch and the functioning prototype. 5- TEST FOR MANUFACTURABILITY The prototype is ready to be tested physically by creating replicas of the part through simple molds. 6- REPEAT AS NEEDED parts which made or used to create the prototype can be re-changed as needed for manufacturability or to minimize the cost. 7- FINAL PRODUCT This is a final stage, the sketch of the prototype is solid. Start contacting supplier & manufacturers to turn the prototype into a mass production. Good luck