Study Question 3: What is a quality-driven

advertisement

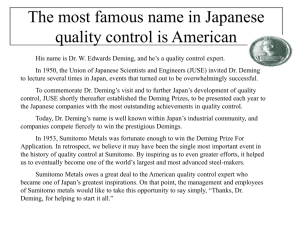

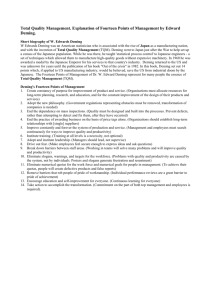

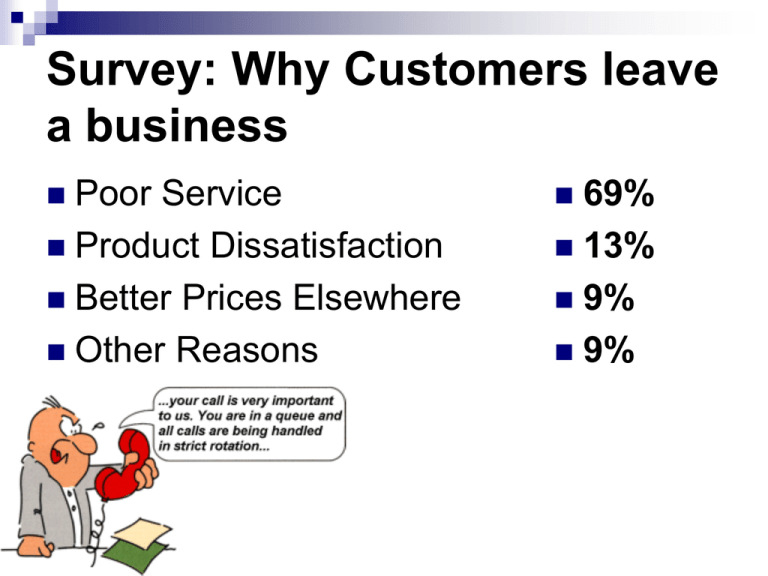

Survey: Why Customers leave a business Poor Service Product Dissatisfaction Better Prices Elsewhere Other Reasons 69% 13% 9% 9% Quality-Driven Organizations Total quality management (TQM): Managing with a commitment to continuous improvement and product quality. Who is Edward Deming Dr. W. Edwards Deming is known as the father of the Japanese post-war industrial revival and was regarded by many as the leading quality guru in the United States. Trained as a statistician, his expertise was used during World War II to assist the United States in its effort to improve the quality of war materials. But then he was invited to Japan at the end of World War II by Japanese industrial leaders and engineers. They asked Dr. Deming how long it would take to shift the perception of the world from the existing paradigm that Japan produced cheap, shoddy imitations to one of producing innovative quality products. Dr. Deming told the group that if they would follow his directions, they could achieve the desired outcome in five years. Few of the leaders believed him. But they were ashamed to say so and would be embarrassed if they failed to follow his suggestions. As Dr. Deming told it, "They surprised me and did it in four years." Deming’s 14 Principles of TQM 1. Constancy of purpose 2. New philosophy 3. Continual improvement, not short-term goals of profitability. Don’t settle for “status quo” Don’t depend on mass inspection Do it right the first time 4. End lowest tender contracts 5. Improve every process Search continually for problems. 6. Use on-the-job training 7. Institute leadership The responsibility of managers must be changed from sheer numbers to quality. 8. Drive out fear 9. Break down barriers 10. No more “smokestacks” Eliminate demand slogans 11. Two way communication Unreasonable demands only create adversarial relationships. Eliminate arbitrary numerical targets Instead look for continual improvement of quality and productivity. 12. Permit pride of workmanship 13. Encourage education 14. Get rid of annual performance ratings of staff that is based purely on numbers. We don’t need just good people; we need people that are improving. Top management commitment and action No hypocrites. TQM Example: Flexible Manufacturing North American vehicle manufacturers have been pursuing and promoting the ability to produce a variable mix of models with the same body shop and assembly line, for example switching between a sedan and an SUV on the fly. Vehicle manufacturers want to avoid repeating Chrysler's situation when they could not produce enough PT Cruisers in Mexico to meet demand, despite having another plant in Illinois that was building the Neon on which the PT Cruiser was based. Instead, vehicle manufacturers want to emulate Toyota, which can produce multiple models and styles from the same plant, or move models to different plants around the world with its Global Body Line (GBL) manufacturing system.