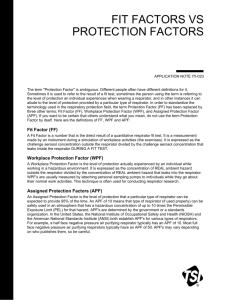

Assigned Protection Factors - define assign -

advertisement

Assigned Protection Factors (APFs) A Need for Harmonization ----Merck’s Experience International Society for Respiratory Protection (ISRP) York, UK - April 11, 2013 Prepared By: Theresa Lane, CIH, CSP, Global Director of IH Erik Kateman, Site IH Oss, NL Presented By: Chris Cooper, Site IH Cramlington, UK 1 AGENDA • • • • • • Background Problem Statement Case Studies Summary Conclusions Recommendations Q & As BACKGROUND – ABOUT MERCK • Merck (MSD) is a global healthcare leader that discovers, manufactures, and supplies innovative human health and animal health medicines, including vaccines • Merck operates in more than 140 countries • Workers must be protected by the hierarchy of IH controls during our development and manufacturing processes BACKGROUND – ABOUT PROTECTION FACTORS • Assigned Protection Factor (APF) - the level of protection that a respirator/class of respirators is expected to provide where an effective respiratory protection program is in place – Established by regulation, consensus groups, and / or suppliers • Nominal Protection Factor (NPF) – minimum level of protection needed to gain “approval” for respirators PROBLEM STATEMENT • NPFs are indicative of laboratory performance; actual performance expected to be less • APFs for same respirator / respirator class are not consistent • Respiratory protection study methods are not consistent, easy to conduct, or transparent – Simulated Workplace Protection Factor Studies (SWPF) – Workplace Protection Factor (WPF) Studies Results in confusion and wasted resources PROBLEMS With CURRENT STUDY PROTOCOLS Determining the “Real” APF • Merck confirms: – Site has implemented an effective Respiratory Protection Program – Respirator’s established APF is founded on scientifically valid and defensible studies • Evaluate SWPF studies against “ORC-like” study protocol sponsored by the pharmaceutical industry • Inconsistencies with study protocols & interpretations • WPF studies extremely difficult to perform within pharmaceutical industry PROBLEMS with Study Design & Data Interpretation Exercises & Equipment Data Evaluation Interpretation EXAMPLES of INCONSISTENCIES Time Sensitivity Type & # of exercises Test subjects Exercises & Equipment Average PF Individual PFs Safety Factors Data Evaluation Interpretations Application of Results Non-detects SWPF WPF Determining the “Real” APF CASE STUDIES - SUMMARY US-OSHA* APF UK-HSE APF Germany APF` Finland APF Manufacturer’s (APF / NPF) Independent (ORC-like - APF) A - PAPR 25/1000* 40 100 200 1000 (APF) 825 B - PAPR 25/1000* 40 100 200 1000 (APF) 715 C - PAPR 25/1000* 40 100 200 1000 (APF) 670 D - SAR 25/1000* - 100 - 1000 (APF) 1000 E - SAR 25/1000* - 100 - 1000 (APF) 1000 F - SAR NA - 100 - 200 (NPF) 1000 G – SAR with blouse NA - 100 - 200 (NPF) 170 Respirator Type *APF of 1000 only where scientifically valid study Same respirator, different protection? Who is to decipher & decide? EMPLOYERS are left trying to define proper protection 9 Establishing APF Values: CONCLUSIONS • Employers must ensure effective RPE program • Regulators & Manufacturers need to identify consistent criteria: – Study type & design • Robust, representative, and transferrable SWPF studies – Data handling & interpretations – Pre-approval / endorsement by regulatory bodies – Management of Change • Users need simplicity and transparency Currently, Employers need to understand how APFs are established to ensure adequate protection Establishing an APF Value: RECOMMENDATIONS • Need consistent, robust and representative criteria – Study design, execution, data evaluation and interpretation – Harmonization – Involvement & approval from regulatory bodies • Need improved transparancy from suppliers • Need easy-to-understand & interpret APFs • Need to identify the “real” APFs Differences in APFs for a given respirator / class, must reflect actual differences in protection and not differences in study protocols or geographical region. Let’s start the dialogue and begin to harmonize! Q&A ACKNOWLEDGMENTS • • • • • Erik Kateman – Oss, NE Chris Cooper – Cramlington, UK Merck’s Independent Testing Lab Respirator manufacturers Merck’s Independent Consultant BACKUP SLIDES 14 References • HSG53 Respiratory protective equipement at work, HSE, 2005. • • Selectie en gebruik van adembeschermingsmiddelen, NVvA, 2001. • NEN-EN 529:2005 Respiratory protective devices –recommandations for selection, use, care and maintanance • • • NEN-EN 14594 • Assigned Protection Factors for the Revised Respiratory Protection standard, OSHA 3352-02 2009. • NIOSH Respirator Selection Logic, N.Bollinger, DHHS Publication No. 2005100 • • • AIHAJ 62:595–604 (2001) Simulated Workplace Protection Factor Study of Powered Air-Purifing and Supplied Air Respirators, AIHAH (62) 2001. Respiratory Protective Equipement, R.M. Howie, OEM 2005 (62) 423-428 Workplace Protection Factors – Supplied Air Hoods, T.J. Nelsen, AIHAJ (62) 2001 Merck-sponsored SWPF studies & consultant reviews Respirator manufacturers’ sponsored SWPF studies