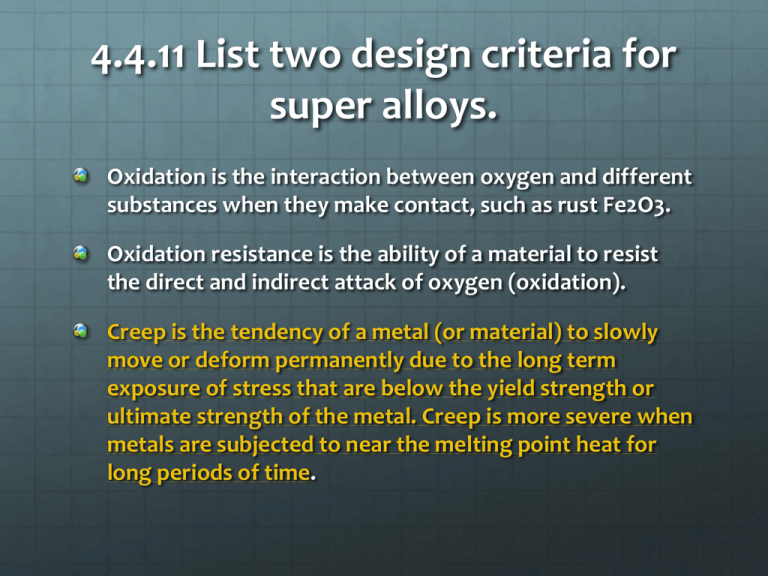

4.4.11 List two design criteria for super alloys.

advertisement

4.4.11 List two design criteria for super alloys. Oxidation is the interaction between oxygen and different substances when they make contact, such as rust Fe2O3. Oxidation resistance is the ability of a material to resist the direct and indirect attack of oxygen (oxidation). Creep is the tendency of a metal (or material) to slowly move or deform permanently due to the long term exposure of stress that are below the yield strength or ultimate strength of the metal. Creep is more severe when metals are subjected to near the melting point heat for long periods of time. CONTINUED CONTINUED 4.4.12 Identify applications for super alloys. Super alloys can be based on iron, cobalt or nickel. Nickel-based super alloys are particularly resistant to temperature and are appropriate materials for use in aircraft engines and other applications that require high performance at high temperatures, for example, rocket engines, chemical plants. Super alloys are used where there is a need for high temperature strength and corrosion/oxidation resistance. CONTINUED Other uses of super alloys are: aircraft and industrial gas turbines, space vehicles, submarines, nuclear reactors, military electric motors and heat exchanger tubing. The space shuttle uses a super alloy for its body and main engine and other parts likely to be exposed to high temperature such as combustion zones also.