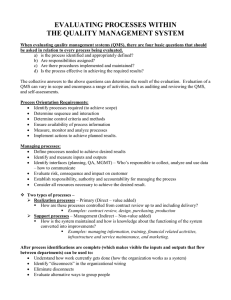

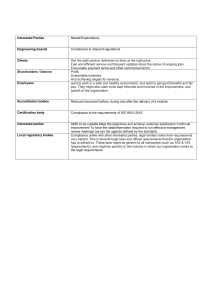

Our Quality Management System is not used! Paper summary • • • It is very difficult to have an efficient and effective Quality Management System (QMS). Creating and maintaining a QMS is for organisations normally not core business. And what if you are a company that wants to start developing and manufacturing for instance medical devices on top of the existing portfolio of non medical systems? How can the QMS help you with serving both product lines? This presentation gives an overview on how to design, deploy and maintain an efficient and effective QMS: 1. 2. 3. 4. 5. 6. • • Requirements for the QMS have to be gathered also taking into account the characteristics of the organisation (size, skill level of people, product portfolio, markets, …) Next a suitable QMS design is to be chosen including how tailor towards projects can be achieved Implementation of the design has to be done resulting in the QMS items like procedures and work instructions. Verification of the implementation by means of document review and validation by piloting in a representative project. Production phase of the QMS introduces the most difficult part of the product creation: deployment. How are the employees trained in such a way that everyone in the organisation is skilled enough to work according to the QMS. While working with the QMS, the end users (employees) will submit change requests. How must an organisation act upon these requests? Deploy, deploy, deploy For all steps mentioned above, hints and tips are given coming from real life examples. Not only what to do but also what NOT to do. Examples shown will be based on the international standard ISO 9001. On top of that, requirements according to the medical device standard ISO 13485 are implemented. © Process Vision – Help! Our QMS is not used Slide 2 of 60 The latest version of this presentation • Is to be found on my website www.processvision.nl © Process Vision – Help! Our QMS is not used Slide 3 of 60 Willem van den Biggelaar • Quality and Medical Regulatory Consultant • Certified DEKRA auditor for ISO 9001 / ISO 13485 • Setup several ISO 9001 / 13485 certified Quality Management Systems (QMS) • Previous jobs • Quality Assurance Officer (5 years) • System Tester (1 year) • Embedded software engineer (7 years) © Process Vision – Help! Our QMS is not used Slide 4 of 60 Content • The 6 steps of developing and maintaining a QMS 1. 2. 3. 4. 5. 6. Define Requirements Design Implement & Verify Validate (piloting) Deploy (initial) Under change control • Treat it like a project • FAQ © Process Vision – Help! Our QMS is not used Slide 5 of 60 Like a V-cycle Stakeholders wishes Project Plan Change Requests Quality Manual - Quality Policy - Management Commitment - Organisation - Scope Define Requirements Quality Manual QMS Index - Processes + owners + interfaces - procedures per process - process owner Validate (pilot run) Procedure A process A --- Template A --- Work instruction A --- Guideline A Procedure B process B -- Template B -- Template C Procedure C process A Procedure D process C -- Guideline B Review Reports Verify Design QMS Procedure interfaces - connecting flow charts input/outputs - defining datastores DPQ-0001a2 2009 Sept 15 Version 01 Status: Approved Product Creation Select, monitor and evaluate a supplier How to accept purchased products Purchased Product Acceptance Supplier Management PP Supplier needed PP Product needs Accepted acceptance Product Design, implement, verify and validate Traceability Matrices Product Creation Plan, Specs, Designs, Reports, Manuals PCP Labeling/Translation Requirements DPQ-0028 Product Security & Privacy Reqs DPQ-0035 PCP Disclaimer Be aware. Only the most obvious interfaces are drawn. In real life much more interfaces exist. Commercial docs Design History File Device Master Record Software Tools Validation & Control Start Clinical Evaluation for IVD MD DPQ-0025 PCP SW tool validation reqs for production (ORP) Plan, TestSpec, Report DPQ-0004 PCP Handle changes on approved items Product Change Control DPQ-0002 PCP DPQ-0032 Q&R Enable recall investigations . Enable tracking towards hospitals Safety/security Modules Templates Guidelines Product Traceability DPQ-0013 Work instructions ORP 510k, PMA, CE Performance Evaluation Start Analyze & report Safety & Security aspects Product Risk Management Risk Management File, Risk CR/PRs CR/PRs SW tool validation reqs for development t en st m ue lop req ve De ange Ch Security & Privacy Reqs Safety/security tagged requirements Service docs Transfer DHF / DMR To ORP PCP DPQ-0005 PCP Risk Analysis Needed DPQ-00019 New product Product Labeling Annexes Product Requirements Traceability Traceability needed Products / Services One of the product preservation control measures To where must requirements be traced DPQ-0034 DPQ-0012 Product Creation Process Purchasing Process Regulatory Approval Market Clearance Order Realisation Process DPQ-0031 Customer Service Process Q&R Quality & Regulatory Procedures - scope - input / output / datastores - activity descriptions - responsible roles A input Implement © Process Vision – Help! Our QMS is not used Slide 6 of 60 Deployment / Change Control ;dsa ;lkf asp’;s d fdsafd as fdas A ;dsa ;lkf asp’;s d fdsafd as fdas output A ;dsa ;lkf asp’;s d fdsafd as fdas Training Material What is a Quality Management System? • Describes a set of procedures an organization needs to follow in order to meet its business objectives. • Small organizations: • mostly no official system • just ‘our way of doing things’ • not written down, in the head of the staff. • Organization gets larger • Written instructions about how things are done needed • Assure nothing is left out • Assure everyone knows who needs to do what, when, how. © Process Vision – Help! Our QMS is not used Slide 7 of 60 Why do you need a QMS (stakeholder wish) • Customer demand • E.g. for medical devices, it is essential for a manufacturer that its suppliers are ISO 13485 certified • Organisation communication gets complexer • More people in one discipline, larger projects • Multidisciplinair, e.g. • Designers <-> Testers • Designers <-> Engineers <-> Production • Sales <-> Production <-> Logistics • Improve process / product quality • Standard way of working in order to focus on product © Process Vision – Help! Our QMS is not used Slide 8 of 60 1. Define requirements for a QMS Requirements for the QMS have to be gathered also taking into account the characteristics of the organisation (size, skill level of people, product portfolio, markets, …) © Process Vision – Help! Our QMS is not used Slide 9 of 60 1. Define: Product Market Combination (PMC) • Product examples • Healthcare • Automotive • Machinery • Consumer • Aerospace • Food • Pharmacy • Measurement instruments • Railway • Radio and telecom • Market examples • Europe • USA • Canada • China • Australia • Russia • Asian pacific • Africa • South America Each combination has its own legislation to which you must comply © Process Vision – Help! Our QMS is not used Slide 10 of 60 1. Define: Comply with International standards • Examples of QMS standards ISO 9001 – General standard ISO 13485 – Medical AS 9100 – Aerospace TS 16949 – Automotive TL 9000 – ICT ISO 27001 – IT Security ISO 14001 – Environmental OHSAS 18001 – Occupational health and safety • Which to choose depends on Product Market Combination © Process Vision – Help! Our QMS is not used Slide 11 of 60 1. Define Company Quality Policy © Process Vision – Help! Our QMS is not used Slide 12 of 60 1. Management must show commitment • Let top management have quality on agenda of (yearly) personnel meeting • (Changes to) Quality policy • Metric • Let department managers have quality on (monthly) department meeting agenda • (Changes to) Quality policy • Results internal and external audits • Management must reserve resources for quality • QMS maintenance • Quality Audits © Process Vision – Help! Our QMS is not used Slide 13 of 60 1. Define: Fit to your organisation • Size of organisation • Number and type of departments • Skill and competence level of the employees • Examples Id A B C Product Respiratory medical equipment Printed Circuit Assembly (PCA) Different types of mechatronics products #Staff 10 50 Education Academic, Large experience in product Secondary school 80 Academic Key departments Marketing & sales Development & Engineering Outsourced Production Purchase / Sales Mass production Development & Engineering Prototype production • A: high level procedures leaning on medical standards • B: detailed work instructions for production • C: high level procedures based on different standards © Process Vision – Help! Our QMS is not used Slide 14 of 60 1. What I have seen gone wrong • No or little management commitment, e.g. • “High quality products” is leading in the quality policy but management decides to deliver less quality if that saves money • Not enough resources available for QMS updates / internal audits • People have no idea that what the company quality policy is • Too heavy QMS for an organisation © Process Vision – Help! Our QMS is not used Slide 15 of 60 2. QMS architecture & design Next a suitable QMS design is to be chosen including how tailor towards projects can be achieved © Process Vision – Help! Our QMS is not used Slide 16 of 60 2. Design: Well known QMS architecture Quality Manual QMS scope and requirements Quality Policy Organisational structure Processes including owners Mandatory to follow Procedures Annexes: Workinstructions Templates Guidelines Checklists Quality Records © Process Vision – Help! Our QMS is not used Slide 17 of 60 Annexes: Extra help to be more efficient and effective All documents and records that proof that the QMS is executed conform its requirements 2. Design: Traceability between layers Process To which process & owner does a procedure belong Procedure Which template has this procedure Template From which template is this record derived? Quality Record © Process Vision – Help! Our QMS is not used Slide 18 of 60 2. Design: Traceability between layers Ref 1: Example of a procedure that refers to its process (and owner) Process To which process & owner does a procedure belong Procedure Ref 2: Example of a procedure that refers to its templates, guidelines,..... Which template has this procedure Template From which template is this record derived? Quality Record Ref 3: By using the latest released template (id+version), reference 3 is assured © Process Vision – Help! Our QMS is not used Slide 19 of 60 2. Design: the processes • Divide in main processes and supporting processes • Assign process owners: • Design/Own the process • Deploy/Advocate the process • Measure the process • Maintain/Improve the process • Do NOT make the QA manager owner of everything • Processes ≠ Departments! • A product creation process is a divided responsibility not only owned by the development department • Design the interfaces between the processes © Process Vision – Help! Our QMS is not used Slide 20 of 60 2. Design: process overview in one picture Managing Director Business Strategy Process (BSP) Scope Business Strategy & Planning Feed back Sales Roadmapping Business Plan MT Product Creation Process (PCP) New Product Introduction Product Design Require ments D&E Manager DHF Definition & Quotation Concept Design Proto Pilot Series TPD + PR TPD Order + Forecast Customer Procurement & PO control Purchasing (PUR) Commodity Strategy Purchasing Manager Selection Contrac ting Accept / Process Evaluation MPS DMR MPS Production Planning & WO control Manufacturing Process (MAP) Supplier Shipping Planning / Work Order (WO) Ready Purchase Order (PO) / Forecast Warehouse (Receival) Manufacturing Manager Warehouse (Expedition) Stock Quality Assurance / Production Engineering (QA/PE) Incoming Inspections CTQ/CTS, Non Conforming Goods, SPC, Calibration QA & PE Manager FEBV Support HRM QESH ICT © Process Vision – Help! Our QMS is not used IT Manager Q/HSE HR Manager Manager Slide 21 of 60 Delivery Note (Final) Assembly and testing Handling and Cleaning Parts Supply Chain Manager Logistics (LOG) FInance Facilities Financial Director Financial Director Product DHR 2. Design the procedure interfaces • Allocate to each process the neccessary procedures • Guard the interfaces between the processes • Again, put it all in a picture • Tip: you can use these pictures for training purposes © Process Vision – Help! Our QMS is not used Slide 22 of 60 2. Design: Procedure interface per process © Process Vision – Help! Our QMS is not used Slide 23 of 60 2: Design: Guard the interfaces © Process Vision – Help! Our QMS is not used Slide 24 of 60 2. What I have seen gone wrong • No process owners, QA does all the work • Interfaces between procedures not aligned • No overview of processes or procedures just a bunch of “howto’s”. • No strict division between QMS items (Q manual, procedures and annexes) and Quality Records © Process Vision – Help! Our QMS is not used Slide 25 of 60 3. Implementation & Verification Implementation of the design has to be done resulting in the QMS items like procedures and work instructions. Verification of the implementation by means of document review © Process Vision – Help! Our QMS is not used Slide 26 of 60 3. Write the procedures • Don’t let key users be authors • Most of the time they don’t have the time for it • Most of the time they are not keen on doing it • Most of the time they are not capable of doing it • Let stakeholders review (walkthrough) them: • Process owner (if not author) • Process owners for which their process interface • Key users – can I use it? Is it complete? • Quality Manager – is it compliant with regulatory © Process Vision – Help! Our QMS is not used Slide 27 of 60 3. Tailoring (deviation of) the QMS • Always allow projects to tailor towards own needs • Let tailoring be documented in the project plan • Let tailoring be approved by the QA manager • Tailoring must be compliant with regulations • If much tailoring occurs, its a signal that perhaps the QMS is not suitable to the needs of the organisation © Process Vision – Help! Our QMS is not used Slide 28 of 60 3. Write the templates and forms • Basis for the quality records so be precise • First make mother template(s)/form(s) • Layout • Default content • Next, make templates/forms for all possible document types • Input • Mother template/form • Best practices • Procedures • Again let stakeholders review (walkthrough) them © Process Vision – Help! Our QMS is not used Slide 29 of 60 3. Write the other annexes • If needed, guidelines • If needed, checklists • If needed, work instructions • In native language if users are native speakers only • Again let stakeholders review (walkthrough) them • Checklists can evolve during history of the organisation, if same things go wrong over and over again, put them in checklists © Process Vision – Help! Our QMS is not used Slide 30 of 60 3. Write training material • While writing you already have to replace yourself in the minds of the users of the QMS • And maybe find out • A procedure has become much too complex • A template is not usable • ......... © Process Vision – Help! Our QMS is not used Slide 31 of 60 3. Deal with different regulations • Suppose your organisation makes products for both medical and non medical industry • Either write different procedures for each industry • Or address the difference within the procedures & templates. E.g. © Process Vision – Help! Our QMS is not used Slide 32 of 60 3. What I have seen gone wrong • Local department templates and work instructions not under QMS control • No mother templates so no escape if a template is not available leading to non compliant project documentation • Procedures long (lot of text, no pictures) and tedious © Process Vision – Help! Our QMS is not used Slide 33 of 60 4. Validate the QMS validation by piloting in a representative project. © Process Vision – Help! Our QMS is not used Slide 34 of 60 4. Validate the QMS: choose pilot projects • Try to validate QMS on all its possible intended uses • Choose (if possible) • Different type of projects. E.g: • 1 Medical project • 1 Machinery project • Different size of projects. E.g.: • 1 very small projects (1 – 10 FTE) • 1 very large project ( 50+ FTE) • 1 medium project (10 – 50 FTE) • Choose projects that are just started • Each project leader will have a “reason” not to be chosen • Projects with high time pressure are reluctant to be chosen © Process Vision – Help! Our QMS is not used Slide 35 of 60 4. Validate the QMS: process the results • Let projects log all issues they come across • Implement the issues in the QMS • Review changes with stakeholders © Process Vision – Help! Our QMS is not used Slide 36 of 60 4. What I have seen gone wrong • No piloting at all, simply “dump” the new process into live projects • Only piloting with a small (easy) non typical project © Process Vision – Help! Our QMS is not used Slide 37 of 60 5. Initial deployment Production phase of the QMS introduces the most difficult part of the product creation: deployment. How are the employees trained in such a way that everyone in the organisation is skilled enough to work according to the QMS. © Process Vision – Help! Our QMS is not used Slide 38 of 60 5. Deployment - training • Create training plan: who must be trained in what and when (input is QMS index) • Initial training of people • Re-train people pro-active (regular basis) or re-active (if needed) • Don’t forget training program for new employees • Let QA officer / Process Owner check by • Sanity checks (coffee corner, project meetings) • Official audits © Process Vision – Help! Our QMS is not used Slide 39 of 60 5. Deployment – explain via wall posters • Use posters on walls, coffee corners, team rooms, etcetera • Also put in FAQ’s, contact persons • Explain them to the team • If changes are due, hang new posters • And re-explain • The team can never say again “we didn’t know” © Process Vision – Help! Our QMS is not used Slide 40 of 60 An example Master Integration Plan Hardware release cycle not included Red Sticker Not standalone testable subsystem A & B Both released by preSIT owner (IM) SRT PDC 30.xx Subproj TM: timing + Q Test team: execution ART/SAT SW TL: timing + Q Dev team: execution Subpro IM: releases SW TL: timing+Q PUBLISHED ACQ 1.3 Pub DB 2.5 Pub HOST 2.6 Pub Infra 4.5 Rel RELEASED Subsys A+B Subsystem A SSAT preSIT Synch Bom Bom Subsystem A internally built & tested PUBLISHED System projects Warroom: accept / reject deliveries ACQ 1.7 Rel DB 2.8 Rel HOST 2.8 Rel GEO 3.1 Rel Infra 4.5 Rel FATs SYSTEM_ INTEGRATED Subsystem B SSAT Bom Bom Subsystem B internally built & tested ACQ 1.3 Pub DB 2.6 Pub HOST 2.6 Pub Infra 4.4 Rel RELEASED Rocket B1 Test dependencies SW TL: identifies & signals conflicts & takes action Subsystem architect PDC 30.xx Existing functionality Rebuild + Regression test with merged BOM Conflicting BOMs Synch System IM: identifies & signals conflicts Subprojects: take action System Regression Test New functionality Test PUBLISHED SSAT PUBLISHED Subsystem D internally built & tested preSIT Synch Subsystem D SSAT ACQ 1.0 Rel DB 1.9 Rel HOST 2.4 Rel GEO 3.5 Rel Infra 4.5 Rel SRT SRS ART/SAT Supply chain subsystem chain per subproject FRS PDC 30.yy ACQ 1.0 Rel DB 1.9 Rel HOST 2.4 Rel Infra 4.5 Rel FAT SDS SIT preSIT Existing functionality MiscSys Viewing PandA Geometry Q: What if a subsystem must deliver at the same time different functionality to 2 or more customers? A: That subsystem can only release if the last customer has released Q: What if a delivery is not on the MIP but is already needed by a customer e.g. due to incompatible interfaces? A: Either change the MIP or deliver that subpart as published to the customer. database ID system warroom - 4 subprojects Production requirements RELEASED Subsys C & D GEO 3.1 Rel Bom New function ality Subsystem C Bom Subsystem C internally built & tested PRS (CIS only) SSIS FAQ Host Blueprint Development chain Scenario 2 UI FSSys Acquisition SIT Standalone testable subsystem C & D Independent released by both subproject IMs SYSTEM_ INTEGRATED Integration dependencies ACQ 1.0 Rel DB 1.9 Rel HOST 2.4 Rel GEO 3.0 Rel Infra 4.5 Rel Bom Other subsystem needed for test new MIP delivery Acquisition B Nijhuis All except Panda, MiscSys, UI modules Database K Oberzynski None FS Sys J Smans Geometry FSFW P Dingemans None Geometry E Suijs None Host F Jacobs None ID P Meuleman ? Infra P Dingemans Yes: IP E Oerlemans Viewing Mercury P Meuleman ? Misc System A v Beurden None Panda A Oberzynska Yes: UI L Berek Viewing, Panda, Geo, Acq, UI modules, Misc Sys UI modules M Boumans None Viewing G Hamerslag IP VxWorks I Canjels ? Subsystems with FSC need FSFW SYSTEM_ INTEGRATED Bom Subsystem System projects Warroom: accept / reject deliveries PDC 30.zz GEO 3.1 Rel Bom SSAT Bom Subsystem C fRole system SCM all functionality mapped on subprojects (Phobos, Acquisition, Eagle, Movement) PDC 30.xx Integrated environment Action points: Zonnetjesplaat Bom System IM: responsible + author New function ality SYSTEM_ RELEASED PDC 30.xx SW TL: timing+ Q Test/Dev team:execution UI modules IP System project Sub(system) project Green Sticker SYSTEM_ TESTED Below two possible scenarios (1 & 2) are given to deliver to the system PDC Pizza items mapped to in-between deliveries based on time Deviations to these scenarios are only allowed if they still comply to the PUBLISHED and RELEASED definitions. target system resources technical dependencies between subsystems (architecture) Scenario 1 Red Color Blue Color Bom SDT: responsible SWAT: author Id: XDB040-043084 Author: W vd Biggelaar Version : 12 Status: Proposal Date: 6 Oct 2004 System Development Cycle Bom Allocation table Pizza items mapped on subsystems C/V PUBLISHED subsystem guarantee and support depends on agreement between involved parties. changes via CR/PR’s after agreement between involved parties on scope (which WIP parts) previously PUBLISHED or higher functionality keeps working: regression tests succeeded agreed new functionality (delivery of MIP) is (partly) implemented dependent on change impact one or more non-official MTs and/or UATs succeeded No part of PDC unless war room decides otherwise C/V RELEASED subsystem official supported release (fixes will be made when users can not wait until the next RELEASED baseline) release note (at least: new functionality; known bugs; solved PRs on previous RELEASED; tests executed & passed) changes via CR/PR’s on those parts that are released (MIP delivery) previous PUBLISHED or higher functionality keeps working: regression tests succeeded agreed new functionality (delivery of MIP) works correctly with its other MIT deliveries official MTs, UATs, SSAT & preSIT succeeded for implemented part as indicated in release note will be part of PDC after acceptance by preSIT owner (see MIP) & system war room War room decides on all conflicting situations Note: CIS delivers PUBLISHED subsystems to C/V. They RELEASE their subsystems at C/V’s SYSTEM_RELEASED SSAT Architecture units per subsystem URS / UDS UAT MRS / MDS MT Code infra © Process Vision – Help! Our QMS is not used Slide 41 of 60 5. Deployment – How to find the QMS • Make several search possibilities • On terms, e.g. via google like search • On lists, e.g via the QMS index list • On pictures – e.g. via a clickable process • Via different views © Process Vision – Help! Our QMS is not used Slide 42 of 60 5. Find the QMS – via clickable process ALL PROCESSES Managing Director Business Strategy Process (BSP) Scope Business Strategy & Planning Feed back Sales Roadmapping Business Plan MT Product Creation Process (PCP) New Product Introduction Product Design Require ments D&E Manager DHF Definition & Quotation Concept Design Proto Pilot Series TPD + PR TPD Order + Forecast Procurement & PO control Purchasing (PUR) Commodity Strategy Purchasing Manager Selection Contrac ting Accept / Process Evaluation MPS DMR MPS Production Planning & WO control Manufacturing Process (MAP) Warehouse (Receival) Delivery Note Manufacturing Manager (Final) Assembly and testing Handling and Cleaning Parts ONE PROCES Shipping Planning / Work Order (WO) Ready Purchase Order (PO) / Forecast Supplier Supply Chain Manager Logistics (LOG) Customer Warehouse (Expedition) Stock Quality Assurance / Production Engineering (QA/PE) Incoming Inspections CTQ/CTS, Non Conforming Goods, SPC, Calibration QA & PE Manager Product DHR FEBV Support HRM QESH ICT FInance Facilities HR Manager Q/HSE Manager IT Manager Financial Director Financial Director ONE PROCEDURE ONE TEMPLATE © Process Vision – Help! Our QMS is not used Slide 43 of 60 5. Find the QMS – template one click away © Process Vision – Help! Our QMS is not used Slide 44 of 60 5. Find the QMS – clickable with different views © Process Vision – Help! Our QMS is not used Slide 45 of 60 5. What I have seen gone wrong • No deployment at all, just issue changes, nobody knows or notices it • Deployment by saying ”Everybody can read the procedure“ • Deployment by going through the procedure step by step in a detailled manner • People have no clue where to find the QMS • And if they have found it, you cannot find what you search for © Process Vision – Help! Our QMS is not used Slide 46 of 60 6. Change Control While working with the QMS, the end users (employees) will submit change requests. How must an organisation act upon these requests? Deploy, deploy, deploy © Process Vision – Help! Our QMS is not used Slide 47 of 60 6. Change Management • Setup a change request tool • Let users submit change requests in a easy way • Form a Change Control Board • Process the change requests on weekly basis • If backlog occurs, you will loose user commitment • Change QMS according to previous mentioned steps • Release on regular basis, e.g. Quarterly and keep deploying • In the end, users must “own” the QMS not QA manager or process owner © Process Vision – Help! Our QMS is not used Slide 48 of 60 6. What I have seen gone wrong • No change control / configuration management / version control leading to • draft procedures being published • Templates being deleted by personell • Large backlog on change requests leading to unmotivated personell to issue new requests © Process Vision – Help! Our QMS is not used Slide 49 of 60 Putting it all together Start a project if you want to create/maintain the QMS © Process Vision – Help! Our QMS is not used Slide 50 of 60 Putting it all together – start a project! • Updating or making a QMS is a normal project • Appoint a project leader • Create a project plan and track progress • Have regular meetings with stakeholders © Process Vision – Help! Our QMS is not used Slide 51 of 60 Example of QMS development plan ISO 13485 project Way of Working and Global Plan Tracking QMS publication board For pilot project(s) Procedures Progress 50 45 40 Axis Title 35 30 walkthroughed 25 proposal 20 QMS publication board For pilot project(s) not existing 15 10 5 0 Stage 1 Training Done Management Review done Process audits done Start Project 01-2010 04-2010 Week 18 Define - Q Manual - Q Index - Pilot project(s) te P r w ub al lish kt hr ou gh Electronic Reviews (no meetings): should only reveal minor issues. Af Walkthroughs of flow charts and proc interfaces at weekly progress meeting leading to informal updates (invite key users) Official e-reviews Q Manual & procedures 08-2010 Week 35 Walkthroughs Process Owners: Write (buddy with WBig) Q Manual / Index - Parts of Procedure Interfaces walkthroughed - Flow charts Pilot projects WBig defined - Total procedure interfaces - Design webinterface All red and orange procedures synchronised with each other (proposal) - Write annexes, check with 1 peer and publish - Xtra text flowcharts (front, back) - connecting flow charts input/outputs - defining datastores Select, monitor and evaluate a supplier PP Supplier needed Product Requirements Traceability Traceability needed Traceability Matrices Product Creation DPQ-0035 PCP Safety/security tagged requirements Commercial docs Design History File Product Risk Management Risk Management File, Risk CR/PRs DPQ-0004 PCP Service docs Device Master Record Software Tools Validation & Control Plan, TestSpec, Report Start Clinical Evaluation for IVD MD DPQ-0025 PCP SW tool validation reqs for production (ORP) Handle changes on approved items CR/PRs SW tool validation reqs for development Analyze & report Safety & Security aspects Product Change Control DPQ-0002 PCP Product Traceability DPQ-0013 DPQ-0032 Q&R input 1 A4 Hints: - merge sequential activities same owner - activities in imperative sense Priorties: Red = High (ISO, needed for project)) Orange = Medium (ISO) Green = Low (non ISO, CCM wish) © Process Vision – Help! Our QMS is not used Slide 52 of 60 ORP 510k, PMA, CE Performance Evaluation Start Enable recall investigations . Enable tracking towards hospitals Safety/security Modules nt st me ue lop req ve De ange Ch Product Security & Privacy Reqs Disclaimer Be aware. Only the most obvious interfaces are drawn. In real life much more interfaces exist. Quality Manual Index File - procedures per process - process owner Plan, Specs, Designs, Reports, Manuals PCP Labeling/Translation Requirements Transfer DHF / DMR To ORP Security & Privacy Reqs DPQ-0005 PCP Risk Analysis Needed DPQ-00019 New product DPQ-0028 PCP Procedure A process A --- Template A --- Work instruction A --- Guideline A Procedure B process B -- Template B -- Template C Procedure C process A Procedure D process C -- Guideline B PP Product needs Accepted acceptance Product Products / Services Design, implement, verify and validate Product Labeling Work instructions To where must requirements be traced DPQ-0034 DPQ-0012 Abbreviation & Definitions file How to accept purchased products Purchased Product Acceptance Supplier Management Guidelines DPQ-0001a2 2009 Sept 15 Version 01 Status: Approved Product Creation One of the product preservation control measures Write / Executing Training. At least: Quality Policy End Q4 2010 - default English - in Dutch if users are Dutch speakers only Procedure interfaces Update of A&D file by all owners QMS approved Annexes Templates Quality Manual - Quality Policy - Organisation - Scope - Processes - Process descriptions - Process Onwers A P Or fter ubl an E-r ish ne ev x w iew rit s te n 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 Product Creation Process Purchasing Process Regulatory Approval Market Clearance Order Realisation Process DPQ-0031 Customer Service Process Q&R Quality & Regulatory A ;dsa ;lkf asp’;sd fdsafda s fdas Flow charts (incl. blue italic) - scope - input / output / datastores - activity descriptions - responsible roles output A ;dsa ;lkf asp’;sd fdsafda s fdas A ;dsa ;lkf asp’;sd fdsafda s fdas A ;dsa ;lkf asp’;sd fdsafda s fdas Stage 2 Certification Gather evidence In pilot Project(s) End Q1 2011 Summary • Did this help to answer the question “What to do if our QMS is not used?” • In short • Treat the QMS as a normal product to be developed, implemented, verified and validated, released, put under change control / version control / configuration management • Treat the way you develop the QMS as a normal project • Deploy, deploy, deploy • The users must feel they “own” the QMS © Process Vision – Help! Our QMS is not used Slide 53 of 60 © Process Vision – Help! Our QMS is not used Slide 54 of 60 • InfoQ did and interview with Willem about the benefits of having a QMS, dealing with multiple regulations, assuring adherence to a QMS, how a QMS can support agility and deploying a QMS in an agile way • A summary is to be found in the upcoming sheets. • The complete interview can be found on http://www.infoq.com/news/2014/10/getting-QMS-used © Process Vision – Help! Our QMS is not used Slide 55 of 60 • In your view what is a QMS? What are the benefits of having one? • A QMS is the documented set of agreements about the way of working within a company • Without this agreement each design project and/or production team works according its own insights which can lead to a wide variation in the quality of products and inefficient work • Can you name some of things that often go wrong when organizations are deploying a QMS? • Problems that I often see in organizations with Quality Management Systems are: • The idea that writing it down is enough • Only performing initial deployment • All deployment by the quality person feeding the idea that the QMS is his/hers responsibility © Process Vision – Help! Our QMS is not used Slide 56 of 60 • From a governance point of view a QMS must assure that applicable regulations are being met. Do you have good practices when dealing with multiple overlapping or conflicting regulations or regulations from different standardization bodies? • You can make a cross matrix to check if all regulations are “in” • I always try not to split up (make separate) procedures but sometimes it can be more convenient: an example is a work instruction to bring a medical device to the market and a work instruction to bring a machinery to the market. • I have not seen any conflicting regulations yet as in principal they all want the same: are you in control © Process Vision – Help! Our QMS is not used Slide 57 of 60 • What can you do to assure that a QMS is followed and adhered to in an organization? • First you need to do proper deployment • Next, check if QMS is followed by official audits and non official “audits” (like listening to people talking in the coffee corner) • You need to re-deploy if issues are found • How can you validate a QMS to see if it supports an organization in reaching it's goals? • You can’t by validating as I described it (piloting) but you can by measuring on the processes. E.g. By means of GQM (Goal Question Metric) method © Process Vision – Help! Our QMS is not used Slide 58 of 60 • If an organization is adopting agile or lean processes would they still need a QMS? • Yes! You always have output so you need templates. You always want a common way of working so you need procedures or work instructions • What kind of changes are needed to a QMS to support agility? • Agility is just a way of working, so write down how you do it and put it in your QMS. I have seen organizations who keep agile development outside their QMS. It became a work instruction in each of their projects. That is not needed and can be ineffective. • Could you develop and implement a QMS using an agile approach, e.g. in iterations in stead of a big bang deployment? • Of course, certainly if you don’t know the exact requirements at the start. You could also develop it while the first project is already running, e.g. the first increment should deliver the requirements and the project management processes © Process Vision – Help! Our QMS is not used Slide 59 of 60 © Process Vision – Help! Our QMS is not used Slide 60 of 60