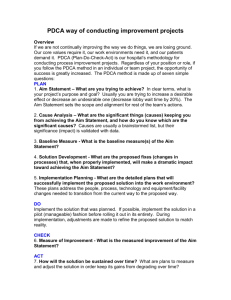

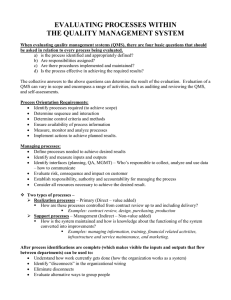

PDCA Cycle (Plan-Do-Check-Act) Plan: • Overall responsibility of top management. • Formulates the quality policy and objectives which describes the intentions and direction of the Management policies as well as its Commitment to Quality. Quality Policy must be communicated within the organization. • In this phase, the organization has to identify the significant processes and prioritize the opportunities for the enhancement of customers’ satisfaction and for the continuous improvement of its operations’ performance. Do: • The stated objectives and processes are now introduced and implemented. • Resources are made available and responsibilities determined. Ensure that employees and other participants are aware of and capable of carrying out their quality management responsibilities. The realization of the quality management system begins. Check: • A QMS requires a process for compliance and valuation of legalrelated regulations. Internal audits can verify that the management system operates properly and generates the planned results. • The processes are monitored with regards to legal, products’ and services’ specifications or other requirements (customer requirements, internal policies) as well as to the objectives of the quality management of the organization. Act: • Top management prepares a evaluation summary based on the internal audit reports called management review. • The results will be evaluated on their performance level and if necessary, corrective or preventive actions can be initiated. • Operations-related processes are optimized and new strategic goals are derived and being set.