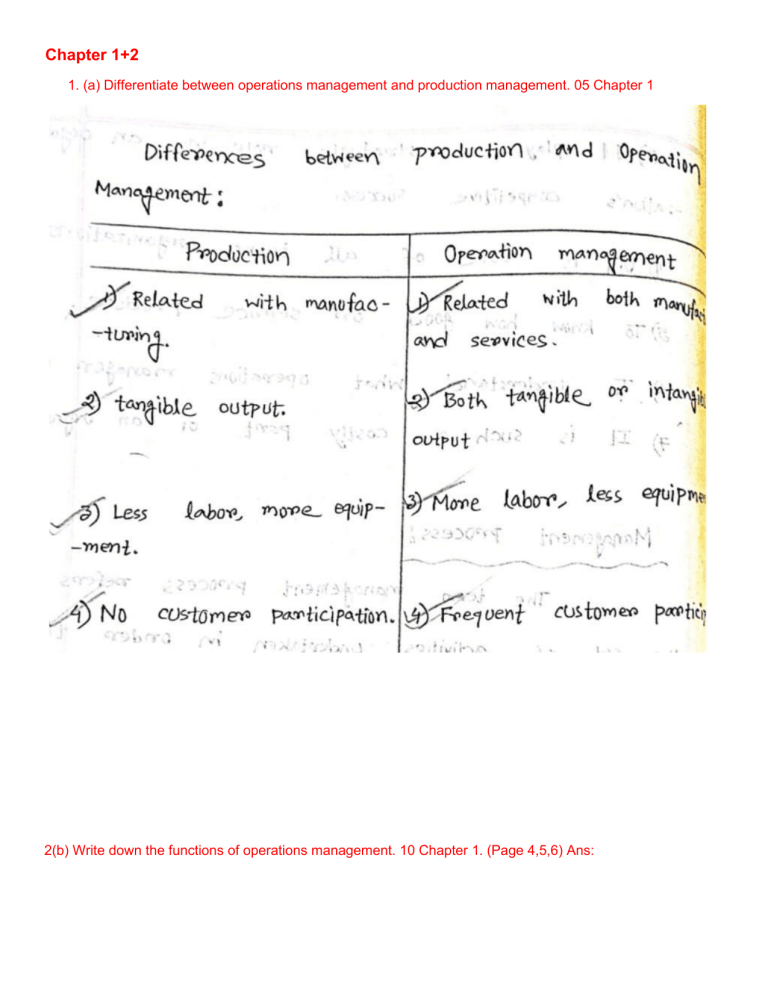

Chapter 1+2 1. (a) Differentiate between operations management and production management. 05 Chapter 1 2(b) Write down the functions of operations management. 10 Chapter 1. (Page 4,5,6) Ans: 3. (c) Discuss different types of production systems. -20 Chapter 1 14. Define Operations Management. -15 Chapter 1 Operations management (OM) is defined as the design, operation, and improvement of the systems that create and deliver the firm’s primary products and services (slide) Operations management is the management of processes or systems that create goods and/or provide services. It encompasses forecasting, capacity planning, scheduling, man aging inventories, assuring quality, motivating employees, deciding where to locate facilities etc. (book) 15. (b) "Production is a value addition process" comment on the statement with an example. 10 27. (b) Clarify the statement, "production is a value addition process". Describe lean production and craft production briefly. (ch-1) 15 Ans lean production System that uses minimal amounts of resources to produce a high volume of high-quality goods with some variety. craft production System is a system in which highly skilled workers use simple, flexible tools to produce small quantities of customized goods 16. (c) What are trade-offs? Why is careful consideration of trade-offs important in decision making? 10 Chapter 1 (pdf Pg 54) Ans: trade-offs A balance achieved between two desirable but incompatible features Operations managers encounter decisions that can be described as trade-off decisions. , the higher the accuracy, the higher the cost, so it is important to weigh cost-accuracy trade-offs carefully. In selecting a piece of equipment, a manager must evaluate the merits of extra features relative to the cost of those extra features. And in the scheduling of overtime to increase output, the manager must weigh the value of the increased output against the higher costs of overtime (e.g., higher labor costs, lower productivity, lower quality, and greater risk of accidents). Careful consideration of trade-offs important in decision making because 26. (a) Describe the nature of the operation manager's job.(ch-1) 10 Ans: The Operations Manager role is mainly to implement the right processes and practices across the organization. The specific duties of an Operations Manager include formulating strategy, improving performance, procuring material and resources and securing compliance Responsibilities • • • • • • • • • • Ensure all operations are carried on in an appropriate, cost-effective way Improve operational management systems, processes and best practices Purchase materials, plan inventory and oversee warehouse efficiency Help the organization’s processes remain legally compliant Formulate strategic and operational objectives Examine financial data and use them to improve profitability Manage budgets and forecasts Perform quality controls and monitor production KPIs Recruit, train and supervise staff Find ways to increase quality of customer service 28. (c) Contrast the terms strategies and tactics. Why is productivity important? (Ch- 2) 10 Ans: Strategies Tactics strategies are the roadmaps for reaching the destinations. Tactics are the methods and actions used to accomplish strategies. Strategies provide focus for decision making. They are more specific than strategies, and they provide guidance and direction for arrying out actual operations, which need the most specific and detailed plans and decision making in an organization strategy is the long-term plan Source: Book Source: Internet Productivity is important because- tactics are the short-term steps that help you hit smaller goals 38. (a) How can you differentiate manufacturing organization from service organization? 06 Ans: We can differentiate them by considering the following points Degree of customer contact. Many services involve a high degree of customer contact then manufacturing. Labor content of jobs. Services often have a higher degree of labor content than manufacturing jobs do Uniformity of inputs. Service operations are often subject to a higher degree of variability of inputs. Measurement of productivity. Measurement of productivity can be more difficult for service jobs due largely to the high variations of inputs Quality assurance. Quality assurance is usually more challenging for services due to the higher variation in input, and because delivery and consumption occur at the same time. Inventory. Many services tend to involve less use of inventory than manufacturing operations, so the costs of having inventory on hand are lower than they are for manufacturing Wages. Manufacturing jobs are often well paid, and have less wage variation than service jobs, which can range from highly paid professional services to minimum-wage workers Ability to patent. Product designs are often easier to patent than service designs, and some services cannot be patented, making them easier for competitors to copy. 39. (b) What are meant by production and productivity? What factors affect productivity? 12 Ans: Production: the production is a value addition process because in the transformation stage value is addedto the input to enhance the quality of the output. Productivity: Productivity is an index that measures output (goods and services) relative to the input (labor, materials, energy, and other resources) used to produce it. It is usually expressed as the ratio of output to input: Productivity=Output/Input Standardizing processes and procedures wherever possible to reduce variability Quality differences may distort productivity measurements. Use of the Internet can lower costs of a wide range of transactions, thereby increasing Productivity Computer viruses can have an immense negative impact on productivity Searching for lost or misplaced items wastes time, hence negatively affecting productivity. Scrap rates have an adverse effect on productivity, signaling inefficient use of resources. New workers tend to have lower productivity than seasoned workers. Safety should be addressed. Accidents can take a toll on productivity. A shortage of information technology workers and other technical workers hampers the ability of companies to update computing resources, generate and sustain growth, and take advantage of new opportunities Layoffs often affect productivity. Labor turnover has a negative effect on productivity; Design of the workspace can impact productivity Incentive plans that reward productivity increases can boost productivity. 40. (c) Can you think of a business that doesn't have operations management? 07 Ans: No, I cannot think of that because operation management is an important part of business organization. Operations management is crucial in a business organization because it helps in efficient management , control and oversee goods, services . Operations is responsible for producing the goods or providing the services offered by the organization. To put this into perspective, if a business organization were a car, operations would be its engine. And just as the engine is the core of what a car does, in a business organization, operations is the core of what the organization does. Operations management is responsible for managing that core. Hence, operations management is the management of systems or processes that create goods and/or provide services. Operations and supply chains are intrinsically linked and no business organization could exist without both. 53. Define 'Operation' Ans: Operations is that part of a business organization that is responsible for producing goods and/ or services. Chapter-3 Solution to Ch-3 6. (c) Suppose a software producer is about to release a new version of its popular software. What information do you think it would take into account in forecasting initial sales? 08 Chapter 3 (Exercise 18, pdf pg 156) Forecasting: It is a method which is used by the analysts to predict the demand It helps the manufacturers to allocate the resources and the costs associated with the product Forecasting can be conducted through qualitative means and by quantitative means Information technology sector is considered as one of the most prominent sector in the service industry. This sector comprises of the products which generally has a very short life span due to continuous innovations Estimating the demand of a product in this sector is very difficult because of the number of alternative availability and piracy But for a new product with no competitor seems favorable for a company to capture the market To estimate the initial sales of a new version of popular software, the company should take into the account of given below information The company should analyze the trends of the sale of the previous version of the software to determine the forecast for the new version Through this analysis, the company would able to know. who the potential customers are The company should also look for the altematives of that software available in the market Analysis of the alternatives would provide a clear picture that whether their product would meet the customer's demand or not. After doing the general analysis, the company should determine the purpose of the forecast This would help the company to analyze what is to be required to conduct the forecast The company then should analyze the technique and the budget of the forecast accordingly. Whether a qualitative of a quantitative method would be beneficial to conduct the forecast After deciding the technique and the budget decision, the company then should follow the plan accordingly It should collect all the relevant data required to conduct the forecast At the end, the company then should monitor the progress of the forecast whether the forecast was effective or not Thus the above mentioned steps would help the company to forecast the demand of the software in the market 17. (a) Define forecasting. What are the limitations of quantitative forecasting techniques? 10 Chapter 3 (exercise 1) Pg 156 Similar question: What are the main advantages that quantitative techniques for forecasting have over qualitative techniques? What limitations do quantitative techniques have? Quantitative forecasts are mathematically computed and are based on numerical data. This numerical data could be further used in modelling to enable the future trends to be predicted These models do also account for trends like seasonality as well as various economic and political conditions However there are some very complex models which are difficult for people to understand and hence, they are averse to using them One of the basic conditions of all simple quantitative methods is that they rely on historical data and also on the fact about what happened in the past would continue to happen in the future. Also they rely greatly on the accuracy of the data being used to apply the quantitative method Quantitative methods are of two types, namely: 1) Time-series forecasts These are a simple attempt to project the past experiences into the future As explained earlier, they attempt to use histoncal data with the premise that the future will be the same as the past. In some models there is an attempt to remove random variation by the use of smoothing techniques Others try to identity patterns and apply them without determining the cause of the patterns 2) Associative models These are models where there is a relationship between certain variable and the data. Because of this, these are called associative since the results use certain causal or explanatory variables to generate a forecast. This results in a causal relationship to be established between any occurrence and its effect on the forecast and the resulting demand Quantitative forecasts are usually preferred over qualitative forecasts for the simple reason that they are objective, based on data and facts and are therefore impersonal Qualitative forecasts are usually very personal to the people involved in the forecasting and therefore are very subjective and quite unreliable However, there are circumstances where one does not have an option but to go in for a qualitative forecast. This is when there is a sharp change in the market conditions and there is no time to gather data and analyze the same. In such situation the only option is to rely on experience and the intuitive opinion of the managers. Quantitative methods of forecasting have a major flaw as it assumes that what happened in the past will continue to occur in the future. Hence, by projecting historical data into the future, one is ignoring any rapid economic or political changes that may occur These can only be done by applying qualitative forecasting methods Therefore the best possible alternative is a quantitative forecast that is tempered by an overlay of a qualitative forecast 19. (c) A manager uses this equation to predict demand: y = 10+ st. Over the past eight 17 periods, demand has been as follows: 17 Is the forecast performing adequately? Explain. Chapter 3 (Problem 33 math) pg 164 44. (Solved)(c) Choose the type of forecasting technique (survey, Delphi, averaging, seasonal naïve, trend. or associative) that would be most appropriate for predicting. 05 chapter-3 page -156 exercise-19 i) Demand for mother's day greeting cards. ii) Popularity of a new television series. iii) Demand for vacation on the moon, iv) The impact a price increase of 10 percent would have on sales of orange marmalade v) Demand for toothpaste in a particular super market. text book publishing company has complied data on total annual sales of its business (d) A text book publishing company has complied data on total annual sales of its business texts for the preceding nine years: 15 chapter-3 page -164 exercise-31 45. . i) Using an appropriate model, forecast textbook sales for each of the next five years ii) Prepare a control chart for the forecast using the original data. Use 2s limits ili) Suppose actual sales for the next five years turn out as follows: Is the forecast performing adequately? Explain. An electrical contractor's records during the last five weeks indicate the number of job requests: 07 chapter-3 page -157 exercise-4 46. Predict the number of requests for week 5, using smoothing constant, a-0.30 and 20 for week 2 forecast. 58. The manager of a travel agency has been using a seasonally adjusted forecast to predict demand for packaged tours. The actual and predicted values are following table: 15 (11th edition, Chapter-3, Page-163, Problem28) i) Compute MAD for the fifth period, then update it period by period using exponential smoothing with x = 0.3. ii) Compute a tracking signal for periods 5 through 14 using the initial and updated MADs. If limits of ±4 are used, what can you conclude? Chapter-11 20. (a) What is meant by aggregate planning? Why is there a need for aggregate planning? Ans: In the spectrum of production planning, aggregate planning is intermediate-range capacity planning that typically covers a time horizon of 2 to 12 months, although in some companies it may extend to as much as 18 months. It is particularly useful for organizations that experience seasonal or other fluctuations in demand or capacity. The goal of aggregate planning is to achieve a production plan that will effectively utilize the organization’s resources to match expected demand. Planners must make decisions on output rates, employment levels and changes, inventory levels and changes, back orders, and subcontracting in or out. Aggregate planning is required to meet the aggregate forecast of demand in the intermediate range. This can be for a period of 3 months to 12 months. In certain cases it can even be as less as one month. Aggregate planning is basically required so deal with variations in the demand over the intermediate range. This can be done by manipulating the employee strength, output principles as well as the inventory policy. All these can be adjusted according to the needs imposed on the system due to the variations as well as the business policies of the firm. Aggregate planning is initially, basically a budgeting exercise which as time progresses, becomes an exercise in trying to keep the business policies intact while trying to satisfy the demand within the restrictive parameters of inventory, back-log and overtime/sub-contracting. Managers usually have to consider numerous strategies before the zero in on the most optimal one for the current scenario. The crucial thing is that these pains have to be updated as and when the situation demands. 21. What are the inputs to master scheduling? What are the outputs? Ans: The master schedule is the heart of production planning and control. It determines the quantities needed to meet demand from all sources, and that governs key decisions and activities throughout the organization. Inputs The master schedule has three inputs: the beginning inventory, which is the actual quantity on hand from the preceding period; forecasts for each period of the schedule; and customer orders, which are quantities already committed to customers. Other factors that might need to be taken into consideration include any hiring or firing restrictions imposed by HR, skill levels, limits on inventory such as available space, whether items are perishable, and whether there are some market lifetime (e.g., seasonal or obsolescence) considerations. Outputs The master scheduling process uses this information on a period-by-period basis to determine the projected inventory, production requirements, and the resulting uncommitted inventory, which is referred to as available-to-promise (ATP) inventory. Knowledge of the uncommitted inventory can enable marketing to make realistic promises to customers about deliveries of new orders. 47. (a) What is disaggregation? Why is it done? Ans: • For the production plan to be translated into meaningful terms of production, it is necessary to disaggregate the aggregate plan. • This means breaking down the aggregate plan into specific product requirements in order to determine labor requirements (skills, size of workforce), materials, and inventory requirements. • To put the aggregate production plan into operation, one must convert, or decompose, those aggregate units into units of actual product or services that are to be produced or offered. • For example, televisions manufacturer may have an aggregate plan that calls for 200 televisions in January, 300 in February, and 400 in March. This company produce 21,26, and 29 inch TVs, therefore the 200, 300, and 400 aggregate TVs that are to be produced during those three months must be translated into specific numbers of TVs of each type prior to actually purchasing the appropriate materials and parts, scheduling operations, and planning inventory requirements. 9. (b) Mention the advantages and disadvantages of chase approach and level approach of aggregate planning Ans: Level capacity strategy Maintaining a steady rate of regular-time output while meeting variations in demand by a combination of options. Capacities (workforce levels, output rates, etc.) are kept constant over the planning horizon. A level strategy works best when inventory carrying costs and backlog costs are relatively low. Advantage: • Stable output rates and workforce levels. Disadvantages: • Greater inventory costs. • Increased overtime and idle time. • Resource utilizations that vary over time. chase demand strategy Matching capacity to demand; the planned output for a period is set at the expected demand for that period. Capacities (workforce levels, output rates, etc.) are adjusted to match demand requirements over the planning horizon. A chase strategy works best when inventory carrying costs are high and costs of changing capacity are low. Advantages: • Investment in inventory is low. • Labor utilization is kept high. Disadvantage: • The cost of adjusting output rates and/or workforce levels. 59. (a) What is meant by aggregate production planning? What are the inputs and outputs of an aggregate production plans? Ans: Aggregate planning is essentially a “big-picture” approach to planning. Aggregate planning begins with a forecast of aggregate demand for the intermediate range.This is followed by a general plan to meet demand requirements by setting output, employment, and finished-goods inventory levels or service capacities. Managers might consider a number of plans, each of which must be examined in light of feasibility and cost. If a plan is reasonably good but has minor difficulties, it may be reworked. Conversely, a poor plan should be discarded and alternative plans considered until an acceptable one is uncovered. The production plan is essentially the output of aggregate planning. Aggregate plans are updated periodically, often monthly, to take into account updated forecasts and other changes. This results in a rolling planning horizon (i.e., the aggregate plan always covers the next 12 to 18 months). Aggregate planning inputsand outputs: 60. (b)Briefly explain the strategies generally followed for aggregate production planning. 10 Ans: Aggregate planning strategies can be described as proactive, reactive, or mixed. Proactive strategies involve demand options: They attempt to alter demand so that it matches capacity. Reactive strategies involve capacity options: They attempt to alter capacity so that it matches demand. Mixed strategies involve an element of each of these approaches. 61 Ans: 34. (c) Prepare a schedule where the forecast is 90 units for each of the first three periods and 70 units for each of the next three periods. The starting inventory is 20 units. The company uses a chase strategy for determining the production lot size, expect there is anupper limit on the lot size of 80 units. Also. The demand safety stock in 10 units. Note: The ATP quantities are based on maximum allowable production and do not include safety stock. Committed orders are as follows: Solution to Ch-11 8. (a) Why is there a need for aggregate planning? 05 Chapter 11 32 (a) What is agreement (Aggregate) planning? What is its purpose? pg-537 05 (ch -11) 10. (c) Manager TC Downs of plum engines, a procedure of lawn mowers and leaf blowers, must 18 develop an aggregate plan given the forecast for engine demand shown in the table. The department has a normal capacity of 130 engines per month. Normal output has a cost of 560 per engine. The beginning inventory is zero engine. Overtime has a cost of $90 per engine. Develop a chase plan that matches the forecast and compute the total cost of your plan 18 Chapter 11 (exercise 5, page 503) 22. (c) Wormwood limited, produces a variety of furniture products. The planning committee wants to prepare an aggregate plan for the next six months using following information: Subcontracting can handle a maximum of 10 units per month. Beginning inventory is zero. Develop a plan that minimizes total cost. No back orders are allowed. Chapter 11 (Problem 9 math) NOT SURE! 33. (b) Manager T.C Downs of plum engines, a procedure of lawn mowers and leaf blowers, must develop an aggregate plan given the forecast for engine demand shown in the table. The department has a normal capacity of 130 engines per month. Normal output has a cost of $60 per engine. The beginning inventory is zero engine. Overtime has a cost of $ 90 per engine. (ch- 11, exercise 5, page 503) 20 Similar math solution for question 34. 34. (c) Prepare a schedule where the forecast is 90 units for each of the first three periods and 70 units for each of the next three periods. The starting inventory is 20 units. The company uses a chase strategy for determining the production lot size, expect there is anupper limit on the lot size of 80 units. Also. The demand safety stock in 10 units. Note: The ATP quantities are based on maximum allowable production and do not include safety stock. Committed orders are as follows: (ch- 11, similar of exercise 22, page 541) 10 48.Solution 49. Michigan Manufacturing produces a product that has a 6-month demand cycle. Each unit requires 10 worker-hours to produce, at a labor cost of $6 per hour regular rate (or $9 per hour over time). The total cost per unit is estimated at $200, units can be subcontracted at a cost of $208 per unit. There are currently 20 workers employed in the subject department, and hiring and training costs for additional workers are $300 per person, where layoff costs are $400 per person. Company policy is to retain a safety stock equal to 20 percent of the monthly forecast, and each month’s safety stock becomes the beginning inventory for the next month. There are currently 50 units in stock carried at a cost of $2 per unit-month. Unit shortage, or stock outs has been assigned a cost of $20 per unit month. Three aggregate plans are proposed. Plan 1: Vary work force size to accommodate demand. Plan 2: Maintain constant workforce of 20, and use over time and idle time to meet demand. Plan 3: Maintain constant workforce of 20, and build inventory or incur stock out cost. The firm must begin January with the 50-unit inventory on hand. Compare the costs of the three plans in table form. P.T.O Chapter-16 11. (a) Briefly describe the following priority rules (0) FCFS (0) SPT () EDD (iv) 50 (v) Rush First come, first served (FCFS): Jobs are processed in the order in which they arrive at a machine or work center. Shortest processing time (SPT): Jobs are processed according to processing time at a machine or work center, shortest job first. Earliest due date (EDD): Jobs are processed according to due date, earliest due date first. Critical ratio (CR): Jobs are processed according to smallest ratio of time remaining until due date to processing time remaining. Slack per operation (S/O): Jobs are processed according to average slack time (time until due date minus remaining time to process). Compute by dividing slack time by number of remaining operations, including the current one. Rush: Emergency or preferred customers first 23. (a) What is meant by job shop scheduling? Job-shop scheduling Scheduling for low-volume systems with many variations in requirements. The characteristics of low-volume systems (job shops) are considerably different from those of high- and intermediate-volume systems. Products are made to order, and orders usually differ considerably in terms of processing requirements, materials needed, processing time, and processing sequence and setups. Because of these circumstances, job-shop scheduling is usually fairly complex. This is compounded by the impossibility of establishing firm sched ules prior to receiving the actual job orders. Job-shop processing gives rise to two basic issues for schedulers: how to distribute the workload among work centers and what job processing sequence to use. 12. (b) Differentiate between job-shop scheduling and flow-shop scheduling Why scheduling is fairly complex for job shops systemis? A group of five jobs us to be processed through a two-machine how shop Use Johnson's rule to obtain the optimum sequence that will mununize the total completion time for thes group of jobs Also draw the Giant chart for this sequence and calculate percentage of idle time for each machine arrival. ii) For each of the methods in part (i), determine, the average job flow time, the average tardiness iii) Is one method and the superior number of to jobs the others? at the work Explain. center. The following table contains information concerning four jobs that are awaiting 37 79 24 processing at a work center. i) Sequence the jobs using FCFS, SPT, EDD andCR. Assume the list is by order of 1 24 24 6 2.27 37 work centers. ii) Construct a chart of the activities at the two centers and determine each one's idle time, assuming no other activities are involved. Given the operation times provided: i) Develop a job sequence that minimizes idle time at the two Consider the following 3 machines and 5 jobs flow shop problem. Check whether Johnson’s rule can be extended to this problem. If so, what is the schedule and the corresponding makespan? 16 (1) 5 5 52 The following table contains order-dependent setup times for four-jobs. For safety reasons, Job C cannot follow job A, nor can job A follow job C. Determine the processing sequence that will minimize the total setup time A-D-B-C A-B-D-C 2+4+3+3 = 12 2+5+2+6 = 15 processing. sequence. using i) ·FCFS ii) SPT and iii) EQD. For each method find the average job flow time and the 'average job tardiness. . Given the following information on job times and due dates, determine the optimal Solution to Ch-16 24. (b) What are the Gantt charts? How are they used in scheduling? 16 (exercise 3) Pg 740,741 10 Chapter 23. a) What are the basic assumptions of the assignment method of linear programming? 10 11. (a) Why are priority rules needed? 25. (c) The times required to complete each of eight jobs in a two-machine flow shop are shown in the following table. Each job must follow the same sequence beginning with machine A and moving to machine B. 15 Chapter 16 (Problem 10 math) (i) Determine a sequence that will minimize make span time. (ii) Construct a chart of the resulting sequence, and find machine B's idle time. 63. A group six jobs is to be processed through a two-machine flow shop, The first operation involves cleaning and 'the second involving painting. Determine a sequence that will minimize the total completion time for this group of jobs, idle time for each work center. Processing times arc as follows: (11th edition, Chapter-16, Page-754, Example-04) - 36 37 51sim 52 64 12. Why scheduling is fairly complex for job shops systemis? 10 50. What are the main decision areas of job-shop scheduling? Job-shop processing consists of 2 main decision areas for schedulers: how to distribute the workload among work centers and what job processing sequence to use. Loading: Loading refers to the assignment of jobs to processing (work) centers. Loading decisions involve assigning specific jobs to work centers and to various machines in the work centers. Sequencing Determining the order in which jobs at a work center will be processed 45. (d) A text book publishing company has complied data on total annual sales of its business texts for the preceding nine years: 15 . i) Using an appropriate model, forecast textbook sales for each of the next five years ii) Prepare a control chart for the forecast using the original data. Use 2s limits ili) Suppose actual sales for the next five years turn out as follows: Is the forecast performing adequately? Explain. = 9×2756.1−45×503 = 9∗285−45×45 =4.01 503 − 4.01 × 45 = 35.833 9 The equation: 𝑦 = 𝑎 + 𝑏𝑥 𝑦 = 35.833 + 4.01𝑥 Here, x = number of years, so forecast for next five years is – Period Forecast(𝒚 = 𝟑𝟓. 𝟖𝟑𝟑 + 𝟒. 𝟎𝟏𝒙) 10 75.98 11 79.99 12 84.02 13 88.04 14 92.05 Formulase = Demand - Forecast |e| = Absolute error e2 = e*e MSE (F1) = Total of e2 / (Total time period-1) = 15.1665 / (9-1) = 1.89 s = √1.89 = 1.376 Control limits are : 0± 2(1.376) = 0 ± 2.75