Manufacturing Systems

advertisement

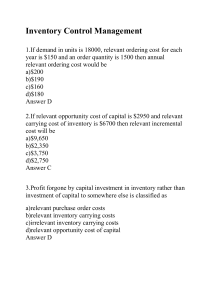

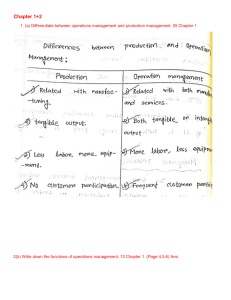

Manufacturing Systems By Dr Mohammed Arif– licensed under the Creative Commons Attribution – Non-Commercial – Share Alike License http://creativecommons.org/licenses/by-nc-sa/2.5/ Manufacturing Systems Integrating Resources to satisfy customers and achieve the strategic goals of the organization Considerations and Constraints • • • • • Product Complexity Construction Systems Delivery Expectations Market Demand Characteristics Physical Considerations Output Measures Input Measures Utilization Peak Capacity Effective Capacity Capacity Cushions Timing and Sizing Expansion Linking Capacity with Other Decisions Estimate Future Capacity Requirements Identify Gaps Develop Alternatives Evaluate Alternatives Dominant factors secondary factors labour climate ability to expand proximity to customers construction costs quality of life for employees proximity to suppliers proximity to parent company’s facility taxes and real estate costs existing transport infrastructure available modes of transportation insurance costs competition for the workforce local zoning and pollution ordinances attitude of community towards their kind of business political stability local laws and regulations cultural factors local taxes and duties connectivity with the outside world weighting the site criteria Break-even analysis Centre of gravity method plan the system plan the use of the system purpose of the forecast time horizon a forecasting technique data Prepare the forecast Monitor the forecast maintain a level of customer satisfaction minimize the cost of storing the inventory (carrying cost) Inventory tracking system Reliable cost information Forecast of demand and lead time Inventory classification system Only one product is considered in the model Demand is reasonably constant Annual demand requirements are known in advance Demand is reasonably constant Lead times are constant Each order is received in single delivery Only one item is considered at a time Annual demand is certain and known The usage rate is constant Usage occurs continuously but the production occurs in batches The production rate is constant Lead time does not vary and is known There are no quantity discounts Total cost = Carrying cost + Ordering cost + Purchasing cost = (Q/2)H + (D/Q)S + PD Test yourself • Manufacturing systems are the glue which holds together the various components which enable an enterprise deliver the end items to its ultimate consumer in a timely manner in conformance with his or her expectation and at reasonable price. (T/F) Ans.T • In Manufacturing Systems each company must consider at least these five factors. (T/F) Ans.T • There are two types of capacity measure, output measures and input measures. (T/F) Ans.T • There are three major capacity strategies. (T/F) Ans.T • Forecasting process can be divided into six major steps. (T/F) Ans.T References • Ferdows, K., (March-April 1997). “Making the Most of Foreign Factories”, Harvard Business Review, 73-88. • Stevenson, W.J., (2004), “Operations Management”, McGraw Hill