Aggregate Planning & Master Scheduling in Production

advertisement

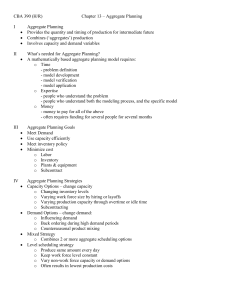

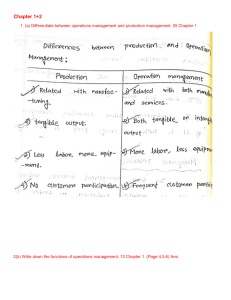

Aggregate planning and master scheduling are critical components of production planning and control. Aggregate planning is a process of determining the overall production levels, inventory levels, and workforce requirements based on the demand forecast. The primary goal of aggregate planning is to balance the demand and supply while minimizing the overall costs associated with production, labor, and inventory holding. Aggregate planning is a long-term planning process that spans six to eight months. Master scheduling, on the other hand, is a short-term planning process that takes the output of the aggregate planning process as its input and considers the capacity constraints to produce a detailed production schedule. The goal of master scheduling is to ensure that the production plan is translated into an achievable plan with specific timelines and quantities. Master scheduling typically covers a shorter span, usually four to twelve weeks, and provides greater accuracy and detail while ensuring that the organization meets its production and delivery goals. In this module, I learned that one of the critical factors in aggregate planning and master scheduling is accurate forecasting. Forecasting techniques like time series analysis, causal models, and regression analysis are used to estimate demand, which is the starting point for all the planning processes. An accurate forecast helps organizations make informed decisions around capacity planning, inventory management, and labor allocation. Furthermore, it also helps organizations meet customer demand while optimizing the use of resources. Another significant factor in aggregate planning and master scheduling is the level of detail and accuracy required at each stage. A high level of detail is required during the master scheduling stage, while a lower level of detail is sufficient during the aggregate planning stage. Organizations must also be flexible in adapting to changes in demand, capacity, or resources, which may require them to revisit and refine their plans. Finally, it is essential to recognize the importance of real-time data and analytics in production planning and control. Real-time data can support organizations in making informed decisions by providing them with accurate information on inventory levels, production rates, and capacity utilization. Analytical tools and technology can further enhance the accuracy and efficiency of the planning and control processes, thereby improving overall organizational performance. In conclusion, aggregate planning and master scheduling are critical components of production planning and control. They provide organizations with a roadmap to effectively manage their resources, meet customer demands, and achieve their financial goals. To ensure success, organizations must be flexible, and adaptable, and leverage real-time data and analytics to optimize their production processes continuously.