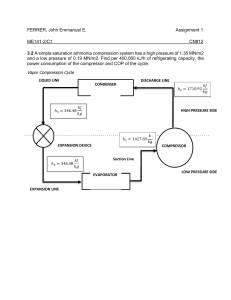

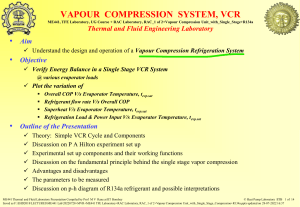

UNIVERSITY OF SOUTH AFRICA SCHOOL OF ENGINEERING CONTINUOUS ASSESSMENT ASSIGNMENT NO: 2 Semester Course SUBJECT CODE: THT3701 SUBJECT NAME: APPLIED THERMODYNAMICS AND HEAT TRANSFER Examiner: Prof CC Enweremadu Moderator: Dr T Sithebe External Moderator: Mr YA Kareem Marks: 50 Weight of Assessment: 5 INSTRUCTIONS TO ALL STUDENTS: 1. Answer all the questions 2. All calculations must be shown 3. All calculations must be rounded off to not more than 3 significant figures 4. You must neither give nor receive aid in the course of writing this assignment. Penalty awaits both givers and receivers. 5. Plagiarism is the act of taking words, ideas and thoughts of others and presenting it as your own. It is a form of theft which involves a number of dishonest academic activities and will be penalised. 6. You must use the unique assignment number 821546 when submitting. 7. You must submit before 23:59 on 2021/08/10 to prevent being timed out. Applicable Graduate Attribute: 7 - Sustainability and impact of engineering activity Demonstrate knowledge and understanding of the impact of engineering activities on society, economy, industrial and physical environment. 1 QUESTION 1 – VAPOUR COMPRESSION CYCLE An ammonia vapor refrigeration cycle operates at an evaporator temperature of –16° C and a condensing temperature of 32 °C. 1.1 (a) Draw the p-h diagram for an ideal saturation cycle and determine the temperature, pressure and enthalpy at all the state points. (7) (b) calculate the coefficient of performance. (2) 1.2 (a) Draw the T-s diagram for wet compression with saturation vapour leaving the compressor and determine the temperature, pressure and enthalpy at all the state points. (7) (b) calculate the coefficient of performance. (2) 1.3 (a) Draw the p-h diagram if the vapour at suction to the compressor is superheated 6 degrees and determine the temperature, pressure and enthalpy at all the state points. (7) (b) calculate the coefficient of performance. (2) [27] QUESTION 2 – VAPOUR COMPRESSION CYCLE A standard vapor compression system produces 70.4 kW of refrigeration using R-12 as a refrigerant while operating between a condenser temperature of 42 °C and an evaporator temperature of –25 °C. 2.1 Draw the p-h diagram of the cycle. (1) 2.2 Determine: (a) the refrigerating effect in kJ/kg, (3) (b) the circulating rate in kg/s, (2) (c) the power supplied, (3) (d) the COP, (2) (e) the heat rejected in kW, and (2) (f) the volume flow rate in m3/s. (3) [16] QUESTION 3 – COMPRESSOR The catalogue for a refrigerant 22, four-cylinder, hermetic compressor operating at 29 r/s. a condensing temperature of 40 °C and an evaporating temperature of -4 °C shows a refrigeration capacity of 96.4 kW. At this operating points the motor (whose efficiency is 90 percent) draws 28.9 kW. The bore of the cylinders is 87 mm and the piston stroke is 70 mm. The performance data are based on 8 °C of subcooling of the liquid leaving the condenser. Compute 3.1 the actual volumetric efficiency and (7) 3.2 the compression efficiency. (5) [12] QUESTION 4 – COMPRESSOR A refrigerant 12 refrigerating system operates with a condensing temperature of 38 °C and an evaporating temperature of –12 °C. The refrigerant leaves the evaporator and enters the compressor at –2 °C. The compressor is a 4-cylinder, V-arrangement 2 single-acting type, direct driven by an electric motor at 875 rpm. The clearance is 5 percent, the capacity is 140.8 kW, bore-to-stroke ratio is 1.25 and the compression is polytropic with n = 1.275 . Evaluate 4.1 the bore and stroke, (13) 4.2 the piston speed, and (2) 4.3 the indicated hp of the compressor. (2) [17] QUESTION 5 – REFRIGERATION LOAD CALCULATION 10 000 kg of dressed poultry are blast frozen on hand trucks each day (24 h) in a freezing tunnel. The poultry is precooled to 7 °C before entering the freezer where it is frozen, and its temperature lowered to –20 °C for storage. The hand trucks carrying the poultry total 700 kg per day and have a specific heat of 0.47 kJ/kg.°C. The specific heat of poultry above and below freezing are 3.18 kJ/kg.°C and 1.55 kJ/kg.°C, respectively, the latent heat is 246 kJ/kg and the freezing temperature is –2.75 °C. Calculate the product load. [8] TOTAL = 3 [80]