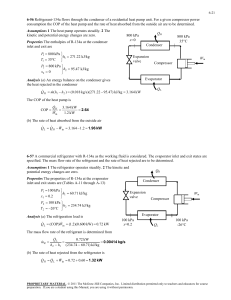

The American University in Cairo MENG 3605 Applied Thermodynamics Lab report #2 Refrigeration & Heat Pump Performance Group members: Enjy Katary 900183501 Mohammed Taha 900183180 Zainab Abdein 900183279 Submitted on 2nd of April Instructor: Dr. Salah El-Haggar TA: Ahmed Sayed 1 Abstract An experiment was conducted on a refrigeration unit to study the cycle and change of states of the refrigeration fluid throughout the cycle. The coefficient of performance varied with the change in the flow rate of the inlet cooling water. The cooled air temperature decreased with the increase in cooling water flow rate and compressor exerted work. 2 Table of Contents List of figures ................................................................................................................................................. 2 List of tables .................................................................................................................................................. 2 Nomenclature ................................................................................................................................................ 3 Introduction ................................................................................................................................................... 4 Objective ....................................................................................................................................................... 5 Theory ........................................................................................................................................................... 7 Description of Experiment & Apparatus ...................................................................................................... 9 Procedure .................................................................................................................................................... 11 Results ......................................................................................................................................................... 12 Discussion: .................................................................................................................................................. 15 Conclusions & Recommendations .............................................................................................................. 17 References ................................................................................................................................................... 18 List of figures Figure 1 TS diagram of ideal refrigeration cycle ........................................................................................... 7 Figure 2 T-s Diagram for first cycle ............................................................................................................. 13 Figure 3 T-s Diagram for second cycle ........................................................................................................ 13 Figure 4 T-s Diagram for third cycle ............................................................................................................ 14 Figure 5 Flow rate vs COP ........................................................................................................................... 14 List of tables Table 1 Experimental Data .......................................................................................................................... 12 Table 2 Experimental Data (2) .................................................................................................................... 12 Table 3 Corresponding Mass flow rate and enthalpy for each point ......................................................... 12 Table 4 Corresponding entropy, power and coefficient of performance ................................................... 12 3 Nomenclature Symbol Units Description H kJ Enthalpy K - Heat capacity ratio 𝒎̇ Kg/s Mass flow rate N rpm Rotational speed P kPa Pressure P W Power Q W Heat transfer T K Temperature U kJ Internal energy V v Voltage W W Work η - Efficiency COP (HP) - Coefficient of performance of heat pump COP (Ref) - Coefficient of performance of refrigerator 4 Introduction The process of heat transfer occurs in nature when there is a difference in temperature between two regions, and the direction of this process is naturally from the higher temperature reservoir to the lower temperature reservoir. In this experiment, the process of heat transfer occurs in the reverse mode from the lower temperature reservoir in a cycle named the refrigeration cycle which needs a power input to operate in contrast to the natural heat transfer process. This cycle takes heat from the lower temperature reservoir, the refrigerator cabinet, to higher temperature reservoir, the room temperature. It is usually found in home fridge that is used to reserve food by keeping it in a low temperature or air conditioners. The working fluid in all previously mentioned refrigerator cycles is the refrigerant which has tabulated properties at different pressures and temperatures. For illustration as shown in figure (1-a), the refrigeration cycle is supplied by 𝑊𝑛𝑒𝑡 to perform its operation which happens as the following: the cycle removes the cooling load 𝑄𝐿 at the lower temperature 𝑇𝐿 and rejects the heating load 𝑄𝐻 is it to the warm environment 𝑇𝐻 . Therefore, it keeps the lower temperature region at a constant low temperature. On the other side of the figure, there is a heat pump which has the opposite objective of keeping the warm places at a constant high temperature𝑇𝐻 which is used in vapor compression cycles. Figure 1) refrigeration and heat pump cycle 5 Ideal cycle: Ideally the refrigerant enters the compressor as a saturated vapor where it gets compressed isentropic ally at constant entropy and therefore it experiences an increase in its pressure and temperature until it leaves in the superheated region. After leaving the compressor, it goes to the condensation device to leave in a saturated liquid form at the same pressure it entered the condenser with while it loses this heat to the environment𝑄𝐿 . Then in order to make a pressure drop to the refrigerant and make it ready to enter the evaporator, it passes through a throttling valve. In the evaporator it gains heat from the low temperature space and it evaporates to reenter the compressor again. Here where the cycle repeats itself to assure constant low temperature in the refrigerating space as shown in figure (2). Figure 2 ideal cycle Practical cycle: In order to reserve the compressor and avoid its damage, in design it is made sure that the refrigerant enters the compressor in a superheated form and not as a saturated vapor. Considering the losses that happens within the pipes due to fluid friction; therefore a significant heat transfer in the pipes because of irreversibility. Since the compressor also operates at a specific efficiency <%100 , it is not expected to have an ideal isentropic compression as shown in figure (3), note the difference between point 2 and point 2’. Due to irreversibility and shifting from the ideal situation, the required power input for the cycle to operate increases and consequently the costs. Figure 3 actual cycle 6 Objective 1. Sketch the cycle on the T-S diagram for performed refrigeration cycle 2. Analyze the performance of that refrigeration cycle by comparing it to the actual cycle 3. Using the measured properties and collected data, calculate the COP, the coefficient of performance for the refrigerator and the heat pump. 4. Plot the relation between the flow rate, the independent variable, and the coefficient of performance, the dependent variable. 7 Theory The refrigeration cycle undergoes four main processes: 1-2 Isentropic compression 2-3 Heat rejection by the condenser 3-4 throttling by the expansion valve 4-1 heat absorption by evaporator Figure 4 TS diagram of ideal refrigeration cycle The whole process operates under steady-flow fluid. Therefore, energy equation can be used to study the mechanism and calculate the COP of the refrigerator and heat pump: (𝑞𝑖𝑛 − 𝑞𝑜𝑢𝑡 ) − (𝑤𝑖𝑛 − 𝑤𝑜𝑢𝑡 ) = (ℎ𝑒 − ℎ𝑖 ) (1) The heat absorbed by the evaporator through process 4-1 can be determined using the following equation: 𝑞𝐿 = 𝑚̇(ℎ1 − ℎ4 ) (2) The compressor work 1-2 can be determined by the following equation: 𝑤̇𝑐 = 𝑚̇(ℎ2 − ℎ1 ) (3) 8 The heat rejected by the condenser: 𝑞𝐻 = 𝑚̇(ℎ2 − ℎ3 ) (4) The cop of the refrigerator when the desired is 𝑞𝐿 is described as the following: 𝑞 𝐶𝑂𝑃𝑅𝑒𝑓 = 𝑤̇𝐿 𝑐 (5) However, when the desired is 𝑞𝐻 the COP is calculated for the heat pump as the following: 𝐶𝑂𝑃𝐻𝑃 = 𝑞𝐻 𝑤̇𝑐 (6) 9 Description of Experiment & Apparatus In this experiment the apparatus shown in figure (6) is replaced by the apparatus shown in figure (5) because the latter apparatus has recording gauges and thermocouples to be used in collecting the necessary data; however, the first apparatus shown in figure (6) has a better display of the components for a better understanding and illustration. The apparatus setup includes the following: 1. A rotameter and its function is to measure the flow rate. 2. A mechanical arrangement of piston-cylinder device to perform the compressor’s function in the refrigeration cycle. 3. A condenser: for heat rejection and transforming the refrigerant to saturated liquid 4. Expansion valve: used to make pressure drop in the refrigerant before entering the evaporator 5. Power switch: supply required power to the cycle 6. Pressure gauges to the record the maximum and minimum pressure limits which mainly happens respectively before and after the compressor. 7. Temperature recording screen: used for data collection to perform the analysis. 8. Temperature knob: To get the reading of temperature at different points in the cycle. - Between the compressor and the condenser - Between the compressor and the expansion valve - Between the expansion valve and the evaporator - Between the evaporator and the compressor - The inlet temperature of the entering water into condenser - The outlet temperature of the water flowing out of the condenser - The refrigerant space temperature 𝑇𝐿 - The room temperature 𝑇𝐻 10 Figure 5) experiment refrigeration apparatus with recording screens Figure 6 refrigeration original setup 11 Procedure 12345- Connect the unit to the cooling water supply. Switch the unit on. Fix the flow rate of the cooling water. Wait for the temperature readings to stabilize. Record the 8 temperature readings, the cooling water flow rate as well as the minimum and maximum pressures. 6- Repeat the experiment with different cooling water flow rates. 7- Ensure the unit is turned off after use. 12 Results Table 1 Experimental Data Volume t1 (°C) t2 (°C) t3 (°C) t4 (°C) t5 (°C) t6 (°C) t7 (°C) t8 (°C) P min flow (gauge) rate (bar) (lit./hr.) 30 45 33 -6 19 21 35 10 20 1.8 50 44 31 -6 21 22 32 10 22 1.8 80 52 31 -3 20 23 31 10 23 2 P max (abs.) (kg/cm^ 2) 9.5 9 8.5 Table 2 Experimental Data (2) Volume t1 (°C) t2 (°C) t3 (°C) t4 (°C) t5 (°C) t6 (°C) t7 (°C) t8 (°C) P min P max flow rate (abs.) (abs.) (m^3/s) (kPa) (kPa) 0.0005 45 33 -6 19 21 35 10 20 280 931.95 0.000833 44 31 -6 21 22 32 10 22 280 882.9 0.001333 52 31 -3 20 23 31 10 23 300 833.85 Table 3 Corresponding Mass flow rate and enthalpy for each point Mass Flow Rate (Water) (kg/s) 0.5 0.833333 1.333333 Mass Flow Rate (R-12) (kg/s) 0.207683 0.243711 0.298479 h1 (kJ/kg) h2 (kJ/kg) h3 (kJ/kg) h4 (kJ/kg) 373.147 232.0735 194.4205 365.1948 373.1747 230.0575 194.4205 366.4537 379.6303 230.0541 197.2038 365.5389 h5 (kJ/kg) h6 (kJ/kg) 87.8955 146.4925 92.081 133.936 96.2665 129.7505 h7 (kJ/kg) 2.87 2.87 2.87 h8 (kJ/kg) 5.74 6.314 6.601 Table 4 Corresponding entropy, power and coefficient of performance s1 s2 s3 s4 Qh (kW) (kJ/kg.K) (kJ/kg.K) (kJ/kg.K) (kJ/kg.K) 1.5614 1.5646 1.588 1.1092 1.1027 1.1028 0.9794 0.9794 0.9897 Ql (kW) Win COP COP (refrigerator) (heat pump) 1.6094 29.2985 35.46684 1.651533 21.4751 17.74019 1.6137 34.87917 41.9263 1.637978 25.59637 21.29403 1.6061 44.64533 50.24447 4.205985 11.94595 10.61472 13 Figure 7 T-s Diagram for first cycle Figure 8 T-s Diagram for second cycle 14 Figure 9 T-s Diagram for third cycle Figure 10 Flow rate vs COP 15 Discussion: The first step in the refrigeration cycle is the compressor. Before and after the compressor, the temperature was recorded for different mass flow rates. The main function of the compressor is to increase the pressure of the refrigerant since the refrigerant enters with low-pressure and low temperature and leaves with higher values. As shown in table 1, adjusting the mass flow rate to 30 l/hr, the pressure increased from 1.8 to 9.5 using the compressor. After that, the condenser removes heat from the refrigerant to condense the water to be in the saturated liquid state. As shown in table 4, the heat rejected increases as the mass flow rate increases. The value increased from 29.2 to 44.6. This can be illustrated using equation (4) since the amount of heat rejected depends mainly on the mass flow rate and temperature change. However, there is an error due to the difference between the temperature at point 3 and the saturation temperate of the measured pressure, which was not equal to zero. This means there is a deviation between the actual temperature and the theoretical one, resulting in inaccurate plotting of the T-S diagram for the three mass flow rates. Then comes the throttling valve, which creates a pressure drop in the refrigerant after it leaves the condenser to help the evaporator perform its function. As shown in table 1, the pressure decreased from 9.5 kPag to 1.8 kPag for the first mass flow rate. The final step is the evaporator which exchanges heat between the cycle and the ambient. It absorbs heat from the ambient following equation 2. As shown in table 4, the value of heat absorbed increased from 35.56 to 50.2 as the flow rate increased. This increase in the values is 16 illustrated using equation (2) which shows a direct relationship between the mass flow rate and the amount of heat absorbed into the system. The COP for the refrigerant and the heat pump was calculated based on three flow rates, as shown in figure (5). COP of the heat pump depends on the amount of heat rejected and the amount of work supplied by the compressor, based on equation (6). Therefore, when the mass flow rate results in a higher difference between enthalpy 2 and 3 than the difference between enthalpy 2 and 1, the COP of the heat pump increases, and vice versa. In this case, it increased from 17.7 to 21.29. The same applies to the COP of refrigeration, and it grew from 21.4 to 25.9, as shown in the plot. This can be described theoretically in terms of temperature and heat transfer. When the flow rate increases, the temperature becomes unstable to adjust to the new change, and then the COP and evaporation temperature decrease. If the heat exchange is assumed to be constant, the amount of work needed to compress the refrigerate is higher. Therefore, the COP decreases. However, the plot didn’t follow this trend due to errors. Sources of error: 1- Inaccurate measurements 2- The device is not calibrated before using 3- The compressor is assumed to be isentropic without heat loses 4- The T taken at the sections was not following the theoretical ones according to the saturation temperatures. 17 Conclusions & Recommendations A direct relation between the mass flow rate flowing in the condenser and the coefficient of performance, The COP, of the cycle was deduced from the findings of this experiment as for the refrigerator and the heat pump cycle. The results showed how the mass flow rate affect the amount of heat rejection at the condenser in case of a heat pump or the amount of heat absorbed by the evaporator. The increase of the entering mass flow rate affects the COP negatively since it increases the amount of power needed for the cycle to operate. Because of human error and irreversibility in the process, the resulted cycle wasn’t ideal and it included some discrepancies, and the value of actual entropy deviated from the ideal expected value. Any point that was plotted on the T-S outside its expected region was neglected and replaced with its theoretical values to perform later calculation and analysis. A possible recommendation to reduce the error in this case is to insulate the compressor to avoid unaccounted and unnecessary heat rejection. 18 References Çengel Yunus A. and M. A. Boles, Thermodynamics: An engineering approach. 8th edition, Singapore: McGraw-Hill Education, 2020. “Thermodynamics & Transport Properties Calculation-refrigerant: Enthalpy: Water&steam: Air,” Thermodynamics & Transport Properties Calculation-Refrigerant | enthalpy | Water&Steam| air. [Online]. Available: http://www.ethermo.us/. [Accessed: 02-Apr-2022].