Guidance for the Implementation of a Quality Management System

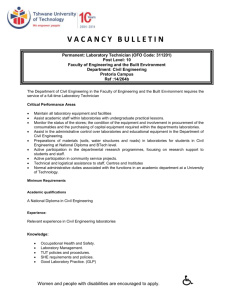

advertisement