Technology Transfer and Commercialization Landscape of the

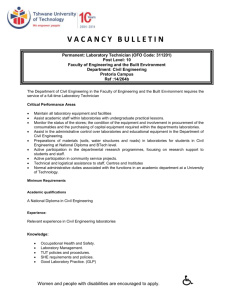

advertisement