Principles - Queensland Health

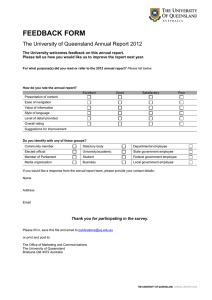

advertisement