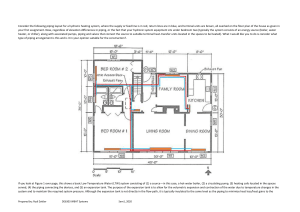

Venturi-tube Lo-Loss Installation

advertisement

Badger Meter Europa GmbH Nürtinger Str. 76 72639 Neuffen (Germany) Tel. +49-7025-9208-0 Fax +49-7025-9208-15 www.badgermeter.de badger@badgermeter.de Venturi-tube Lo-Loss Installation Pressure connections ¼“ NPT. Flange bolt holes must straddle horizontal and vertical centerlines. Badger venturi flow tubes of the insert type must be handled on the outside surface only. If a sling is required, use hemp rope. Bevore installing the primary element, make certain the arrow on the tube is pointed in the direction of flow. Then center the tube into the flow line and clamp between flanges. Suitable gaskets must be installed so they do not protrude inside the pipeline. A straight length of pipe, equivalent to at least eight pipe diameters, should be provided immediately upstream from the tube. Adverse flow conditions will require a greater length of straight piping. Pressure taps on insert tubes are stamped „H“ for high pressure and „L“ for low pressure. These taps are located on opposite sides of the tube and should be placed on the horizontal axis. For liquids, the small bypass hole should be located at the top of the pipe. For stream or gases, the bypass hole should be at the bottom of the pipe. The nameplate designating the top of the flow tube is installed on the mounting flange. A gate valve must be provided near each pressure connection, and all pressure piping should be installed with a minimum one way slope of ¼“ per foot to remote instruments. Wherever possible, avoid sudden changes in pipe direction. If abrupt changes are necessary, use plugged crosses so the pipe can be easily flushed or rodded. Be sure all joints are pressure tight. When making installations of this type, you should carefully observe the grade requirements of horizontal piping, as well as the valve and fitting requirements of the piping layout. Strap the two runs of pressure piping together throughout as much of the run as possible. Ream the ends of the pipe to eliminate inward flares. Do not make connections to any remote instrument until you have flushed out the pressure piping and carefully read the instruction manual for the instrument to be used. VT_BTV_IA_02_0901.doc Reprint of texts or text extracts requires prior written authorization of Badger Meter Europa GmbH. Misuse of texts, pictures or company logo will be prosecuted.