Piping Design Hydronic Heating Floor Plan r1 f77123adebfc25ef2f18e85bba37cfe0

advertisement

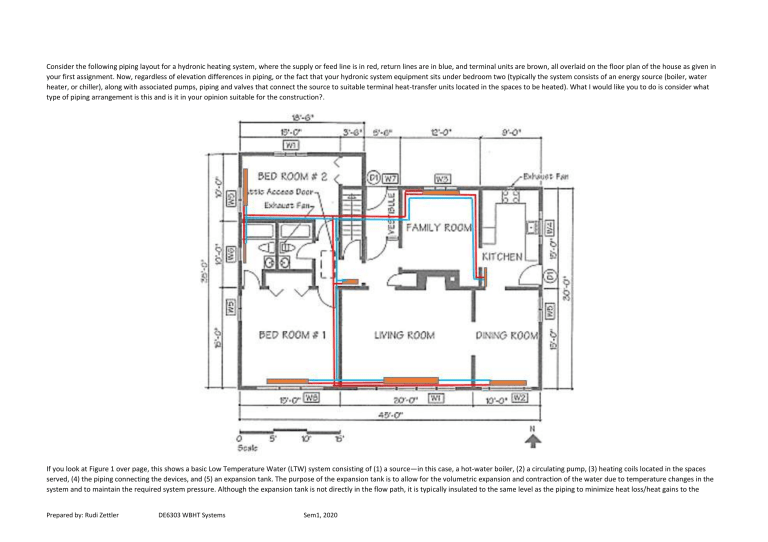

Consider the following piping layout for a hydronic heating system, where the supply or feed line is in red, return lines are in blue, and terminal units are brown, all overlaid on the floor plan of the house as given in your first assignment. Now, regardless of elevation differences in piping, or the fact that your hydronic system equipment sits under bedroom two (typically the system consists of an energy source (boiler, water heater, or chiller), along with associated pumps, piping and valves that connect the source to suitable terminal heat-transfer units located in the spaces to be heated). What I would like you to do is consider what type of piping arrangement is this and is it in your opinion suitable for the construction?. If you look at Figure 1 over page, this shows a basic Low Temperature Water (LTW) system consisting of (1) a source—in this case, a hot-water boiler, (2) a circulating pump, (3) heating coils located in the spaces served, (4) the piping connecting the devices, and (5) an expansion tank. The purpose of the expansion tank is to allow for the volumetric expansion and contraction of the water due to temperature changes in the system and to maintain the required system pressure. Although the expansion tank is not directly in the flow path, it is typically insulated to the same level as the piping to minimize heat loss/heat gains to the Prepared by: Rudi Zettler DE6303 WBHT Systems Sem1, 2020 system. The system in Figure 1 is a direct return system meaning that the first terminal unit to receive heat and return the fluid baring heat, back to the source will be A, and the last to do so will be E. The disadvantage of this direct-return system is that the lengths of the flow paths (and hence the flow resistance) differ for the various terminal units. The flow path through Unit A is significantly shorter than the path through Unit B. The flow rate will be higher through Unit A. The same is true for Units C through E. The flow rates will be different in all the units, and that is undesirable. Balancing valves must be added to allow for balancing the flow after the system is installed. A similar system laid out to Figure 1, but with reverse return is shown in Figure 2 above to the right. The advantage of a reverse-return system is that the flow resistance for each of the individual flow paths is roughly equal, so the system is essentially self-balancing. The reverse-return piping system however is costlier, due to the additional length of return piping required, but is often justified where flow control is critical. Now if we remove the floor plan of the house from our piping layout, as shown in Figure 3 on the right, we can begin to see that what has been proposed looks like a direct return system, which although saving in pipe lenth means there will exist different flow rates in all parts of the system, which will require significan balancing if this systtem is to work. So, the question now is, what can be done in order to better control the flow? One of the possibilities to balance flow has already been demonstrated in Figure 2. However one could also consider an option where the distribution system could be a multiple pipe system for both supply and return. For hydronic systems that provide both heating and cooling, the distribution system may be configured as either a 2-pipe system or a 4-pipe system. Unlike a 2-pipe system, a 4-pipe system gives the operator the ability to circulate both hot water and chilled water during intermediate seasons. Four pipes (2 supply and 2 return) serve separate terminal units. The system is more expensive, since the amount of piping is roughly doubled, but overall occupant comfort is greatly improved. Now over the page is the original line drawing used to produce the piping overlay on the floor plan of the house from assignment 1. Rearrange the pipe layout such that you achieve balance flow throughout the system. Prepared by: Rudi Zettler DE6303 WBHT Systems Sem1, 2020 Figure 3 Boiler Source: http://hohengasser.com/hydronics.php When considering your design use a two pipe system where both pipes ultimately are equal in length and size. In this case the first terminal supplied is the last terminal returned and vise-versa, making it is easy to balance the flow rates. Some ideas for you to consider have been found using the following link: https://www.google.com/search?q=hydronic+piping+design&rlz=1C1CHBF_enNZ885NZ885&tbm=isch&source=iu&ictx=1&fir=w0hdgGKYd8yKnM%253A%252CC6kaoK5966BV1M%252C_&vet=1&usg=AI4_kQifNwZ3uwrBs3ZmfAPrnxVAngPIA&sa=X&ved=2ahUKEwiD_bSx2cboAhWU4zgGHU3uCaEQ9QEwAnoECAMQJQ#imgrc=MQqnL8FhTVwbGM Prepared by: Rudi Zettler DE6303 WBHT Systems Sem1, 2020 Prepared by: Rudi Zettler DE6303 WBHT Systems Sem1, 2020 A Methodology to Follow – Equivalent Pipe Length Methodology An efficient and simple way to calculate the pressure loss in a piping system is to use the "Equivalent Pipe Length Method". Step 1. As you’ve seen me do on the previous page, make a diagram of the piping system and then identify all of the nodes, which make up your system (refer to the link below). These nodes will consist of all the components you use to make up the hydronic heating system e.g. boiler, pump, tees, elbows, expansion tank, valves and terminal units. An example of this and what to do next is given in the following link: https://www.engineeringtoolbox.com/equivalent-pipe-length-method-d_804.html Step 2. Once you’ve identified all the nodes, you then to create a calculation table as shown below. Each section from node to node is calculated by supplying length, volume flow, pipe size, pressure loss from diagrams or tables for the actual pipes and components in the sections and their individual equivalent length substituting the minor loss. You do this by creating or using the spread sheet provided by the link above. Step 3. Add actual pipe sizes and calculate pressure loss, either through the Darcy-Weisbach formula or pressure loss tables for pipes (see also link above) Step 4. Add the equivalent length for all valves, components, fittings and straight pipes in the sections of your table (as above). Step 5. Calculate and summarize the pressure loss in each section. Prepared by: Rudi Zettler DE6303 WBHT Systems Sem1, 2020 Step 6. Finally, summarise the pressure loss in all paths by adding up the pressure loss in all sections of your design that form a unique path. In the example given in the link above there are two unique paths one is section 0 - 2 - 3, the other is section 0 - 2 - 4. Add extra columns for additional paths in more complicated systems, which will be the case for your assignment. Remember the highest pressure loss determines the pump head for which you will then select your circulator/pump. Step 7. Don’t forget to add balancing valves. In the example given in the link Useful references include: https://www.indoorcomfortmarketing.com/how-to-calculate-the-proper-flow-rate-for-anyhydronic-system https://www.centralheating.co.nz/assets/resources/Intro-to-Hydronic-Underfloor-Heating.pdf https://books.google.co.nz/books?id=EgzoB9D4kQC&pg=PA593&lpg=PA593&dq=Example+problem++how+to+calculate+hydronic+heating+equipment+for+typical+house&source=bl&ots=3lpAtHbB6i&s ig=ACfU3U1k5vHzg5SjeyM2xIXZtVToQvT8g&hl=en&sa=X&ved=2ahUKEwiqmaXPn8joAhXJwzgGHaHSA3MQ6AEwDH oECA0QKA#v=onepage&q=Example%20problem%20%20how%20to%20calculate%20hydronic%20heating%20equipment%20for%20typical%20house&f=f alse Prepared by: Rudi Zettler DE6303 WBHT Systems Sem1, 2020 DE 6303 – Water Based Heat Transfer Systems (due on 28th April) Assignment (individual) – Design of a hydronic heating system incorporating domestic hot water supply for a residential building NOTES ON REPORT STRUCTURE 1. Design Specification (5% oa mark) Here you will need to identify the house, the floor plan, the location and what needs to be done i.e. what is the goal of this assignment. 2. Symbols and Equations (5% oa mark) Introduce all symbols and equations used in the document, by name, graphically and stating application. This is typically done in tabular form. 3. Perform Heat Load Calculation (10% oa mark) Here you will tabulate the rooms and allow for estimates of heat load requirements as per the assignment you performed for MG7030. Sum these individual values to determine the total heat load required. 4. Applying the Universal Hydronic Formula (5% oa mark) Once we know the heat load rate (BTU/H) we need to calculate the required flow rate (using the universal hydraulic formula), given inn Gallons Per Minute (GPM). 5. Design Piping Using Equivalent Piping Method (25% oa mark) Conduct steps 1-7 from the “Equivalent Pipe Length Methodology”. In this section you can sketch your design schematic and utilise a table to fill in your Bill of Materials (BoM) and losses (pressure drop) to circulate the necessary GPM. 6. Select Proper Circulator/Burner/Terminal Units/Hot Water Cylinder/Expansion Tank etc. (15% oa mark) Bell & Gossett provided a tool for the hydronics industry called The System Syzer. This tool is very useful in calculating GPM, the proper pipe size to support the GPM and the corresponding pressure drop and velocity for any application. When you Prepared by: Rudi Zettler DE6303 WBHT Systems Sem1, 2020 have checked your calculated pressure drop and the required GPM against the B&G System Syzer, select appropriate components on the internet and tabulate these. 7. Floor Level Schematic c/w Instrumentation Symbols (15% oa mark) Provide a fully instrumented schematic of your design identifying every system component you have used. 8. Appendix (15% oa mark) Here you can provide a spread sheet (if you have used this to perform calculations) or hand worked calculations as evidence. Also include any charts and design specifications (details) of chosen components e.g. Burner, Circulator, Hot Water Cylinder etc. that you have used. Prepared by: Rudi Zettler DE6303 WBHT Systems Sem1, 2020