O&M Manual Outline: Treatment Facilities

advertisement

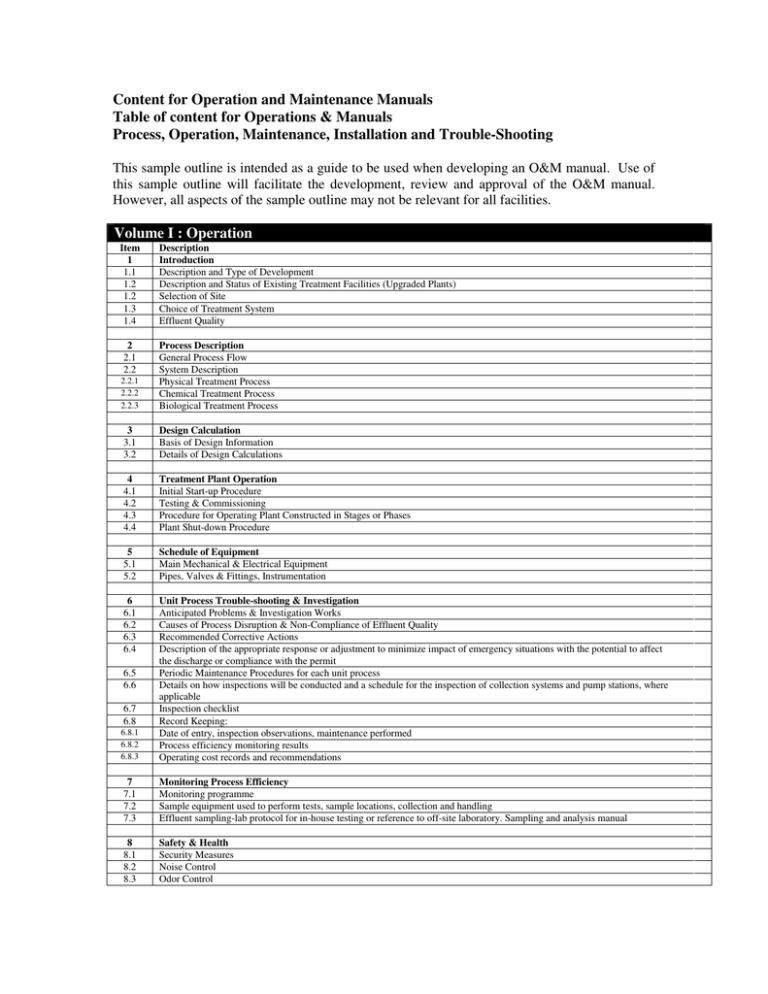

Content for Operation and Maintenance Manuals Table of content for Operations & Manuals Process, Operation, Maintenance, Installation and Trouble-Shooting This sample outline is intended as a guide to be used when developing an O&M manual. Use of this sample outline will facilitate the development, review and approval of the O&M manual. However, all aspects of the sample outline may not be relevant for all facilities. Volume I : Operation Item 1 1.1 1.2 1.2 1.3 1.4 2 2.1 2.2 Description Introduction Description and Type of Development Description and Status of Existing Treatment Facilities (Upgraded Plants) Selection of Site Choice of Treatment System Effluent Quality 2.2.1 2.2.2 2.2.3 Process Description General Process Flow System Description Physical Treatment Process Chemical Treatment Process Biological Treatment Process 3 3.1 3.2 Design Calculation Basis of Design Information Details of Design Calculations 4 4.1 4.2 4.3 4.4 Treatment Plant Operation Initial Start-up Procedure Testing & Commissioning Procedure for Operating Plant Constructed in Stages or Phases Plant Shut-down Procedure 5 5.1 5.2 Schedule of Equipment Main Mechanical & Electrical Equipment Pipes, Valves & Fittings, Instrumentation 6 6.1 6.2 6.3 6.4 6.8.1 6.8.2 6.8.3 Unit Process Trouble-shooting & Investigation Anticipated Problems & Investigation Works Causes of Process Disruption & Non-Compliance of Effluent Quality Recommended Corrective Actions Description of the appropriate response or adjustment to minimize impact of emergency situations with the potential to affect the discharge or compliance with the permit Periodic Maintenance Procedures for each unit process Details on how inspections will be conducted and a schedule for the inspection of collection systems and pump stations, where applicable Inspection checklist Record Keeping: Date of entry, inspection observations, maintenance performed Process efficiency monitoring results Operating cost records and recommendations 7 7.1 7.2 7.3 Monitoring Process Efficiency Monitoring programme Sample equipment used to perform tests, sample locations, collection and handling Effluent sampling-lab protocol for in-house testing or reference to off-site laboratory. Sampling and analysis manual 8 8.1 8.2 8.3 Safety & Health Security Measures Noise Control Odor Control 6.5 6.6 6.7 6.8 Volume I I: Maintenance Item 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 23 25 26 27 28 29 30 31 Description Catalogues, Technical specification, Performance data, Equipment installation, Equipment trouble-shooting, Periodic maintenance procedures, Start-up/shutdown for mechanical & electrical equipment, Spare parts inventory, Certificates of warranty, JPP equipment approval letter, etc. Pump Motor Gearbox Penstock Static Screen Mechanical Screen Screw Conveyor/Compactor Screenings Bin Grit Removal System Grease Removal System Scraper Mechanism Primary Sedimentation Aerators Diffusers Mixers Blowers Main Control Panel Scraper Mechanism Secondary Clarifier Thickeners Dewatering Equipment Disinfection Equipment/Apparatus Measuring Instruments/Devices/Sensors Pipes/Valves/Fittings Lifting Devices Electrical Equipment Diesel Generator Fire-Fighting Equipment Sound-Proof Installations Dryer Odour Control Equipment Progamme Logic Controller Manhole Cover/Grating Volume III : As-Built Drawings Item 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 Description Process, Hydraulic, PID, Layout, Structure, Mechanical, Electrical, Architecture, Schedule, Standard Drawings, etc. Hydraulic profile & Schematic Flow Diagram Schematic Flow Diagram Process & Instrument Diagram (PID) Site Layout Plant Layout Inlet Works (Primary Screen, Wet Well & Dry Well) Secondary Screen & Grit/Grease Chamber Equalisation Tank & Distribution Chamber Aeration Tank Blower House & Control Room Secondary Clarifier Sludge Holding Tank Sludge Digester Sludge Thickener Sludge Dewatering Sludge Drying Bed & Cake Storage Shed Chlorination Plant & Disinfection Tank Effluent Discharge Chamber Perimeter Fencing & Lighting Schematic Line Diagram for Power Supply Instrument Layout of Control Panel Electrical Line Diagram of all Equipment Schedule of Pumps 24 25 26 Item 27 28 29 30 Notes i. ii. Schedule of Other Mechanical Equipment Schedule of Pipes, Valves & Fittings Architectural Drawing of Buildings Description Ladder Diagram for Programmable Logic Controller (PLC) Architectural Drawings Locations of Fire-Fighting Equipment Mass Balance Diagram A draft to be submitted for approval 60 days before date of operation of the facility and if manuals found to be inadequate, the owner is required to make appropriate modifications. A review of the approved manuals one year after initiation of plant operation and subsequent to the review, the manuals shall be revised to reflect actual treatment plant experience.