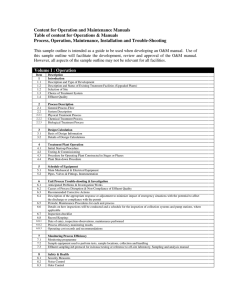

CVNG 3016 DESIGN OF ENVIRONMENTAL ENGINEERING Year 2018/2019 Semester I WASTE WATER TREATMENT PLANT FOR TOWN OF ALEXANDRIA GROUP MEMBERS ID NUMBER DANIELLE BRUCE 815006573 OSAWAI JOHN 815007434 SHIKIEL BRATHWAITE 815008417 MKAMA PETERS 815117301 COURSE COORDINATOR: Dr. Vincent Cooper MODULE LECTURER: Wayne Williams SUBMISSION DATE: 23/11/2018 Table of Contents ABSTRACT .................................................................................................................................... 4 OBJECTIVES ................................................................................................................................. 4 INTRODUCTION .......................................................................................................................... 5 TOWN DESCRIPTION.............................................................................................................. 5 SOIL CONDITIONS &TOPOGRAPHY ............................................................................... 6 CLIMATE ............................................................................................................................... 6 HYDROLOGY ....................................................................................................................... 7 WASTE WATER TREATMENT PLANT DESCRIPTION ..................................................... 7 REASON FOR NEW WASTE WATER TREATMENT PLANT ........................................ 7 DESIGN OF WASTE WATER TREATMENT PLANT ............................................................... 8 RIVER CHANNEL (INLET) ..................................................................................................... 8 CALCULATION: ................................................................................................................... 8 DESIGN CHECK OF CHANNEL: ........................................................................................ 8 PUMPSTATION....................................................................................................................... 10 CALCULATION: ................................................................................................................. 10 RACKS AND SCREENS ......................................................................................................... 14 CALCULATION: ................................................................................................................. 14 GRIT CHAMBER .................................................................................................................... 17 CALCULATION: ................................................................................................................. 17 PRIMARY SEDIMENTATION TANK................................................................................... 18 CALCULATIONS: ............................................................................................................... 18 BIO REACTOR ........................................................................................................................ 20 CALCULATION: ................................................................................................................. 21 CLARIFIER .............................................................................................................................. 25 CALCULATION: ................................................................................................................. 25 GRAVITY THICKENER ......................................................................................................... 28 CALCULATION: ................................................................................................................. 29 AEROBIC DIGESTOR ............................................................................................................ 31 CALCULATION: ................................................................................................................. 31 UV DISINFECTION ................................................................................................................ 34 CALCULATION: ................................................................................................................. 35 SLUDGE DRYING BED ......................................................................................................... 36 CALCULATION: ................................................................................................................. 37 SECURITY ............................................................................................................................... 38 WORKER ACCOMMODATION ............................................................................................ 39 LABORATORY ....................................................................................................................... 40 LAB OCCUPATIONAL HEALTH OF SAFETY ............................................................... 40 TESTS ................................................................................................................................... 42 TREATMENT PROCESSES ....................................................................................................... 46 SCREENING ............................................................................................................................ 46 AERATED GRIT CHAMBER ................................................................................................. 46 PRIMARY TREATMENT ....................................................................................................... 47 PRIMARY SEDIMENTATION TANK............................................................................... 47 SECONDARY TREATMENT ................................................................................................. 47 BIOREACTOR ..................................................................................................................... 47 CLARIFIER .......................................................................................................................... 47 AEROBIC DIGESTER ............................................................................................................. 48 DISINFECTION ....................................................................................................................... 48 SLUDGE DRYING BED ......................................................................................................... 48 LAYOUT OF WWTP ................................................................................................................... 50 CONCLUSION ............................................................................................................................. 51 REFERENCES ............................................................................................................................. 52 APPENDICES .............................................................................................................................. 54 ABSTRACT This report entails the design of a wastewater treatment plant in the town of Alexandria. This treatment facility utilizes the extended aeration for the treatment of wastewater and the design is broken up into each of the unit processes to be carried out at the plant. Within each unit process, step by step design calculations are shown and drawings of the respective tanks are provided. OBJECTIVES 1. To design a waste water treatment facility that is capable of treating waste for an entire town. 2. To be aware and utilize the different standards that exist for designing a waste water treatment facility. 3. To understand the role of each unit process in the treatment of waste water. INTRODUCTION TOWN DESCRIPTION Alexandria is a town located in North Trinidad and is located near the equator. Figure 2 below shows Alexandria town which houses a population of 35250 persons. The town contains many facilities including, recreational parks and a mall, however there is no airport in this town due to its dense population. Placing an airport in this town will result in many residents being displaced or increase in deforestation to make space for such a structure. Therefore, the airport is located outside the of the town. On the Eastern side of the town there is the Cancun forest which is home to capuchin monkeys and macaws. The Alexandrian mall is also located to the East of the town along with the church, nightclub and the hotel, and facilitates many different of activities, such as shopping and cinema. The town’s water treatment plant is located in the North Eastern side of the town which provides the community with potable water. The hospital, fire services, police station and health care centre are all located in the centre of the town which is the most densely populated area and thus allows for a shorter travel distance to these facilities in the event of an emergency. The schools and elderly home are also located in this region and are near to the different emergency services. The Western side of the town has a less densely populated area and is where the waste water treatment plant is to be located. The selected site of the wastewater treatment plant was downstream of the water treatment facility to ensure that there would be no contamination of the surface water that goes into the water treatment plant. Figure 1 Site Map showing Location of Alexandria in Trinidad Figure 2 Town of Alexandria SOIL CONDITIONS &TOPOGRAPHY Alexandria falls within the Tunapuna/Piarco Regional Corporation. The topography of the land is relatively flat, with elevations ranging from 5 m to 49 m. The land slopes to the Western side of the town. The soil in Alexandria belongs to the group of Terrace soil with restricted internal drainage. The town has a soil composition of fine sandy loam. Sandy loam soils have high concentration of sand within the soil that allows relatively quick drainage of water. The natural land found within the town comprises of recreational grounds that are utilized by members of the Alexandria, community. Around some of the residential developments, there is landscape horticulture to add to the aesthetic appeal of the neighbourhoods as well as foster a green environment. CLIMATE The country of Trinidad is located near to the equator, and thus, the town of Alexandria, experiences a tropical climate which is separated into two (2) distinct seasons. These are the dry season and the wet/rainy season. The dry season begins in the month of January and ends in the month of May. Precipitation does not occur often at that time of the year and the daytime is considerably warm. In the rainy season however, precipitation is more frequent and intense. This season begins in late May and ends in early January. During this season the day time is warmer and more humid than the dry season, however, the nights are very cool compared to the nights in the dry season and have stronger winds. HYDROLOGY The town consists of one (1) river. This is the Alexandrian river which flows from the North Eastern side of the town and ends on the South Western side of the town. Apart from the river, there are also two (2) aquifers. The first aquifer is located near to the water treatment facility while the second aquifer is located nearer to the densely populated areas of the town. These aquifers are used for obtaining potable water for the town when the water level in the river is low. Since the land is sloped to the West, when precipitation occurs, the water flows in the Western direction. The town is not located near the coastline and has a generally low water table, however, as previously mentioned, the land is relatively flat and therefore, there is some risk of flood occurrence on the land near to the river WASTE WATER TREATMENT PLANT DESCRIPTION REASON FOR NEW WASTE WATER TREATMENT PLANT Currently, Alexandria does not have a waste water treatment plant. Instead, each structure has at least one (1) septic tank and soakaway that assists in the treatment of the waste water before it is released into the environment. As previously mentioned, the town does not usually have a high water table, however during the rainy season, excessive rainfall causes an increase in the water table. Recently, the town’s water treatment plant found evidence of coliform in the water and made a report. Upon investigations it was revealed that the waste water released from the soakaway was seeping into the ground water causing contamination of the water source in the densely populated area in the town. There have also been reports concerning the failure of soakaways on the North Western side of the town. For this reason, a new waste water treatment plant is required to prevent further contamination of the water source. DESIGN OF WASTE WATER TREATMENT PLANT RIVER CHANNEL (INLET) CALCULATION: Channel Dimensions: Using Q = 68235 m3/d = 0.79 m3/s and va = 0.7 m/s Q = Ava 𝑄 A=𝑣= 0.79 0.7 A = 1.13 m2 𝐵 Assuming Width to Depth Ratio, 𝐷 = 2 B = 2D A = B x D = 2D x D A = 2D2 2𝐷 2 = 1.13 𝑚2 01.13 D=√ 2 = 0.751 m ∴ B = 2D = 2(0.751) = 1.50 m Using freeboard, f = 0.6 m Dt = 1.351 m DESIGN CHECK OF CHANNEL: Net cross-sectional area: An = B x D = (1.5) x (0.751) An = 1.128 m2 Wetted perimeter: Pw = 2D + B = 2(0.751) + 1.50 Pw = 3 m Hydraulic radius: 𝐴 R = 𝑃𝑛 = 𝑤 1.128 3 R = 0.376 m Slope: 1 S = 1000 S = 0.001 m Flow through velocity: Using roughness coefficient (Concrete lined), n = 0.013 and Manning’s equation 1 v = 𝑛 𝑅32 𝑆21 1 2 1 1 v = ( ) (𝑅 3 𝑆 2 ) = ( 𝑛 2 1 ) ((0.376)3 (0.001)2 ) 0.013 v = 1.266 m/s Since 1.266 ms-1 > 0.7 ms-1, the design is OK! Table 1 River Channel Design RIVER CHANNEL DESIGN Parameter Value Peak flow, Q 68235 Cross-sectional area, A 1.13 Net cross-sectional area, An 1.128 Width of river channel, B 1.5 Depth of river channel, D 0.751 Total depth of channel, Dt 1.351 Wetted perimeter, Pw 3 Hydraulic mean radius, R 0.376 Channel slope, S 0.001 Flow through velocity, v 1.266 Assumed Parameters Assumed velocity, va 0.7 Manning’s coefficient of roughness, n 0.013 Width to depth ratio, B/D 2 Freeboard, f 0.6 Units m3/d m2 m2 m m m m m m m/s m/s m/s m/s PUMPSTATION The well is to be constructed with sulphate resistant reinforced concrete to withstand chemical reactions of the wastewater. Pipes for wastewater should be greater than 4 inch to maintain velocity above 0.6 m/s. Design is to have adequate space for pumps, to facilitate cleaning, and to have sufficient volume. Spacing between pumps should correspond to the diameter of the pumps; the distance of the pumps near walls is to be half the diameter of the pump. Distance from the wall to the centre of the pump impeller should be 1.5 times the pump diameter. The wet well would be designed to have 4 pumps. CALCULATION: Wet Well Active Volume: Using minimum cycle time, T = 10 mins and q = 68235 m3/d = 47.385 m3/min 𝑉𝑤𝑤 = 𝑇𝑞 𝑉𝑤𝑤 = (10)(47.385) Vww = 473.85 m3 Dimensions of wet well: Using Vww = 473.85 m3 and an assumed well depth, Dww = 4.5 m 𝑉 Aww = 𝐷𝑤𝑤 𝑤𝑤 Aww = 473.85 4.5 Aww = 105.3 m2 Conditions of the incoming and discharge sewers: 1. Size of incoming sewer: 609.6 mm (24”) SDR 41 2. Bottom Elevation of incoming sewer= -8.55 m 3. Pressure Pipe Bottom Level= 3 m 4. Size of inner diameter: 577.80 mm (22.748”) 5. Length: 800 m Gravity Flow Pipe: 1. Bottom Level: 3m 2. Diameter: 609.6 mm (24”) Pump Diameter: Pump diameter for pump #1, dp = 14.25 in Pump diameter for pump #2, dp = Water Head: 1. Suction water level = -8.55 m 2. Pressure Pipe Bottom Level = 3 m Discharge Water Level = Pipe Bottom Level + Diameter Discharge Water Level = 3 + 0.578 Discharge Water Level = 3.578 m 3. Actual Head, H = 3.578 – (-8.55) H = 12.13 m 4. Total head loss by pump equipment Table 2 Pump Station Design PUMP STATION DESIGN Parameter Peak flow, Q Pumping rate for a single pump, q Active volume of wetwell, Vww Area of wetwell, Aww Actual head, H Discharge water level Length of wetwell, Lww Width of wetwell, Www Assumed Parameters Minimum cycle time between pump starts, T Design volume of wetwell, Vdes Depth of wetwell, Dww dp (Pump #1) dp (Pump #2) Value 68235 47.385 473.85 105.3 12.13 3.578 11.92 5.52 Units m3/d m3/min m3 m2 m m m m 10 140 4.5 14.25 min m3 m in m Figure 4 Showing Horizontal Section of Wet Well Figure 3 Showing Vertical Section of Wet Well Table 3 Selected Pump Specifications Pump Specifications Flygt N-Technology N 3301 LT 3 phase 8p SmartRun 60hz Pump Pumping Rate (m3/h) 1368 Max Head, h (m) 9.65 Motor Output (kW) 44.7 Efficiency (%) 79.5 Height (m) 1.71 Width (m) 1.44 RACKS AND SCREENS Screening is one of the first operations at the wastewater treatment plant. The screening device’s main function is to remove large object present in the wastewater. The performance of screens depends on the bar spacing. Screens can be cleaned by removing them manually or by the process of backwashing. It must be noted that the frequency of cleaning of the screens all depends on the quality of wastewater entering the plant. - Coarse Screens - Fine Screens Provide two identical barracks, each capable of handling max flow. One screen chamber could be taken out of service for routine maintenance without interrupting the normal plant operations. CALCULATION: Clear areas through rack opening: Using Q = 68235 m3/d = 0.79 m3/s and va = 0.7 m/s 𝐴𝑐𝑙 = 𝐴𝑐𝑙 = 𝑄 𝑣𝑎 0.79 0.7 𝐴𝑐𝑙 = 0.658 𝑚2 Clear width of opening at rack: 𝑊𝑐𝑙 = 𝑊𝑐𝑙 = 𝐴𝑐𝑙 𝐷 0.658 = 0.876 𝑚 0.751 Number of spacings: Using Wcl = 0.876 m = 876 mm and assuming bar width of 1 cm =10 mm and clear spacing is 2.5 cm = 25 mm 𝑁𝑠 = 𝑊𝑐𝑙 = 35 𝑠𝑝𝑎𝑐𝑖𝑛𝑔𝑠 𝑆𝑐𝑙 𝑁𝑠 = 876 = 35 𝑠𝑝𝑎𝑐𝑖𝑛𝑔𝑠 25 Total number of bars: Nb = Ns – 1 Nb = 35 – 1 = 34 bars Width of chamber: Using bar width, Wb = 10 mm = 0.01 m 𝑊𝑐ℎ = 𝑊𝑐𝑙 + 𝑁𝑠 𝑊𝑏 Wch = (0.876) + (35)(0.01) =1.226 m Bar efficiency: E= E=( 𝑆𝑐𝑙 × 100 𝑊𝑐ℎ 25 × 35 1226 ) × 100 = 71 % Head Loss: Case 1: Bars are unclogged Using va= 0.7 m/s; vb = 1.266 m/s and c1 = 0.7 ℎ𝐿 = ℎ𝐿 = 1 (𝑣𝑏2 −𝑣𝑎2 ) ∗ 𝑐 2𝑔 1 (1.266 2 − 0.7 2 ) [ ] = 0.081 𝑚 0.7 2(9.81) Case 2: Bars are clogged Using v1= 0.7 m/s; v2 = 1.266 m/s and c2 = 0.6 ℎ𝐿 = ℎ𝐿 = 1 (𝑣𝑏2 −𝑣𝑎2 ) ∗ 𝑐 2𝑔 1 (1.266 2 − 0.7 2 ) ∗ = 0.095 𝑚 0.6 2(9.81) Table 4 Racks and Screens Design RACKS AND SCREENS Parameter Value Peak flow, Q 68235 Clear areas through rack space, Acl 0.658 Clear width of opening at rack, Wcl 0.876 Depth of river channel, D 0.751 Number of spacings, Ns 35 Number of bars, Nb 34 Width of chamber, Wch 1.226 Efficiency, E 71 Head loss, hL (Unclogged) 0.081 Head loss, hL (Clogged) 0.095 Assumed Parameters Assumed velocity, va 0.7 Clear spacing, Scl 0.025 Bar width, Wb 0.01 Acceleration due to gravity, g 9.81 Approach velocity, v1 0.7 Velocity through bar openings, v2 1.266 Head loss coefficient, c 0.7 (Unclogged) Head loss coefficient, c (Clogged) 0.6 Units m3/d m2 m m m % m m m/s m m m/s2 m/s m/s - GRIT CHAMBER Providing two identical basins, each capable of handling max flow, one could be taken out of service for routine maintenance without interrupting the normal plant operations. CALCULATION: Volume of aerated grit chamber: Using Q = 68235 m3/d = 0.79 m3/s and DT = 3 min = 180 seconds 𝐷𝑇 𝑉𝑎𝑔 = 𝑄 ( ) 2 Vag = (0.79) ( 180 2 ) Vag = 71.1 m3 Grit Chamber Geometry: Width-depth ratio for aerated grit chambers range from 1:1 to 5:1. Depths range from 2.1 to 4.87 m. Using a width-depth ratio of 1.2 and a depth, Dg = 2.5 m Wg = 1.2Dg Wg =1.2(2.5) = 3 m 𝑉𝑔 Lg = 𝑊 𝑔 𝐷𝑔 𝐿𝑔 = 71.1 = 9.5 𝑚 3 × 2.5 Length check: Assuming a freeboard, f = 0.4 m Length-width ratios range from 3:1 to 5:1. Length to width ratio for the aerated grit chamber sized 9.5 above is: 3 = 3.17:1, which is acceptable. Required air supply: The air supply requirement for an aerated grit chamber ranges from 0.185 to 0.46 m3/min·m. of chamber length. Using 0.35 m3/min·m 𝐴𝑖𝑟 𝑟𝑒𝑞𝑢𝑖𝑟𝑒𝑑 = 𝑎𝑖𝑟 𝑠𝑢𝑝𝑝𝑙𝑦 𝑟𝑒𝑞𝑢𝑖𝑟𝑚𝑒𝑛𝑡 × 𝐿𝑔 Air required = (0.35)(9.5) Air required = 3.33 m3/min Total air supply required = (3.33)(2) Total air supply required = 6.66 m3/min Quantity of grit expected: Using grit collection rate of 0.10x10-3 m3 𝑉𝑔 = 𝑄 × 𝑔𝑟𝑖𝑡 𝑐𝑜𝑙𝑙𝑒𝑐𝑡𝑖𝑜𝑛 𝑟𝑎𝑡𝑒 𝑉𝑔 = (0.79)(0.10 x 10-3) Vg = 7.9 x 10-5 m3/s = 6.83 m3/d PRIMARY SEDIMENTATION TANK CALCULATIONS: Number of tanks = 4 Number of trains = 2 Flow per tank: Using Q = 68235 m3/d and assuming that each train will be able to take the design flow 𝑄𝑡 = 𝑄 𝑚3 /𝑑 𝑁𝑢𝑚𝑏𝑒𝑟 𝑜𝑓 𝑡𝑟𝑎𝑖𝑛𝑠 68235 3 𝑚 /𝑑 2 𝑄𝑡 = Qt = 34118 m3/d Volume of tank: Using an assumed detention time, DT = 2 hours = 0.08 days and Q = 34118𝑚3 /𝑑 V = QtDT V = (0.08)(34118) V = 2843 m3 Area of tank: Assuming a side water depth, Dsw = 4.5 m and freeboard, f = 0.5 m A=𝐷 𝑉 𝑠𝑤 +𝑓 = 2843 4.5+0.5 A = 569 m2 ≈ 570 𝑚2 Tank diameter: 2𝜋𝑟(𝑑𝑐 + 𝑓𝑐 ) + 𝜋𝑟 2 570 = (2)(3.142)𝑟(4.5 + 0.5) + (3.142)𝑟 2 Solving the above equation quadratically r = 9.34 m ≈ 10 𝑚 ∴ 𝑑 = 2𝑟 = 2(10) d = 20 m Surface overflow rate: 𝑆𝑂𝑅 = 𝑄𝑡 34118 = 𝐴 570 SOR = 60 m3/m2/d Recommended overflow rates range from 60 to 120 m3/d/m2 ∴ 60 𝑚3 /𝑚2 /𝑑 is okay Table 5 Primary Sedimentation Tank Design PRIMARY SEDIMENTATION TANK DESIGN Design Parameters Value Units Peak flow rate, Q 68235 m3/d Flow rate per clarifier, Q 34118 m3/d Volume per clarifier, V 2843 m3 Area of clarifier, A 569 m2 3 Surface overflow rate, SOR 60 m / m2/d Assumed Parameters Number of primary clarifiers 4 Number of trains 2 Detention time, DT 2 hours Side water depth D 4.5 m Freeboard, f 0.5 m BIO REACTOR The bio-reactor is also commonly known as the aeration tank and its purpose is to provide the waste water with sufficient oxygen to ensure that aerobic bacteria do not die and cause the water to become septic. There are many different systems that may be used for the aeration process such as the sequence batch reactor, oxidation ditch, rotating biological contactor along with a few others. However, the membrane bio-reactor is the most common system used for aeration purposes. In terms of aeration there are also different methods of introducing oxygen into the tank in the activated sludge process such as diffused air aeration, mechanized aeration and combined aeration. In diffused air aeration there is the option of selecting fine bubble diffuser and coarse bubble diffuser. The fine bubble diffuser operates by introducing air into the tank through pipelines at the base which then go through the water and appear as bubbles on the water surface. It is called the fine bubble diffuser since the bubbles on the surface are very small compared to the coarse bubble diffuser which are larger. In terms of efficiency, fine bubble diffusers are the better selection since it introduces more oxygen into the tank due to slow rising of the air bubbles and the system is easier to maintain than coarse bubble diffusers. Therefore, for the design of the bioreactor for Alexandria a fine bubble diffusion system was selected. The air is pumped into the aeration tank using one or more blowers. The water entering the tank is mixed with sludge that has been taken from the secondary clarifier to be reused. It is important to maintain the required sludge mass in the aeration tank since the sludge helps to remove the bacteria from the water. However, too much sludge in the aeration tank may result in air not being efficiently distributed throughout the water which is extremely important in the aeration process. In Alexandria, the aeration tank is used for the extended aeration treatment process. As, previously mentioned a fine bubble diffuser will be used to supply the wastewater with sufficient air needed for the survival of the aerobic bacteria in the tank. A total of four (4) four tanks were selected to be designed in two (2) trains where each train has the capacity to carry the full flow of the wastewater to ensure that efficiency of the plant is not reduced in the even that one of the trains may need to be shut down and serviced. The following calculations were carried out to produce the final design of the aeration tanks and the selection of a suitable diffuser to be used for aerating the wastewater. CALCULATION: Number of aeration tanks = 8 Number of trains = 2 Number of tanks per train = 4 Design flow per aeration tank: Using a design flow, Q = 68235m3/d 𝑄𝑖 = 𝑄𝑑 68235 = 𝑛𝑢𝑚𝑏𝑒𝑟 𝑜𝑓 𝑡𝑟𝑎𝑖𝑛𝑠 2 Qi = 34118 m3/d = 34118000 L/d Flow per aeration tank: 𝑄𝑡 = 𝑄𝑖 34118 = 4 4 Qt = 8529 m3/d Volume of wastewater per train: Assuming X = 4000 mg/L, BOD5 = 200 mg/L and F/M = 0.10 𝐹 𝑄𝐵𝑂𝐷5 = 𝑀 𝑉𝑡 𝑋 𝑉𝑡 = (34118000)(200) 𝑄𝐵𝑂𝐷5 = 𝐹 (0.10)(4000) (𝑀 ) 𝑋 𝑉𝑡 = 17058750 𝐿 = 17059 𝑚3 Volume of sludge returned to aeration tank: Assuming 25% additional volume due to returned sludge Using 25% = 0.25 Vsr = % returned x Vt = 0.25 x 17059 Vsr = 4265 m3 Total volume of aeration tank: V = Vt +Vsr V = 17059 + 4265 V = 21323 m3 Total volume per tank: 𝑉𝑡𝑎𝑛𝑘 = 𝑉 21323 = 𝑛𝑢𝑚𝑏𝑒𝑟 𝑜𝑓 𝑡𝑎𝑛𝑘𝑠 𝑝𝑒𝑟 𝑡𝑟𝑎𝑖𝑛 4 Vtank = 5331 m3 Hydraulic retention time: 𝜃= 𝑉𝑡𝑎𝑛𝑘 5331 = 𝑄𝑖 34118 θ = 0.16 days Tank dimensions: Assuming a freeboard, f = 0.5 m and depth, d = 4.5 m 𝐴𝑖 = 𝑉𝑡𝑎𝑛𝑘 5331 = 𝑑+𝑓 4.5 + 0.5 Ai = 1066 m2 Using a width to depth ratio of 2.5 W = 2.5dt = (2.5)(5) W = 13 m ∴𝐿= 𝐴𝑖 1066 = 𝑊 13 L = 85 m Air Requirements: Using BOD5 = 200mg/L = 0.2 kg/m3 BOD5 Loading = BOD5Qt = (0.2)(8529) BOD5 Loading = 1705.9 kg/m3 Oxygen transfer rate: Assuming 2kg of oxygen is required to remove 1kg of BOD5 OTR = BOD5 Loading x 2 = 1705.9 x 2 OTR = 3412 kg/day Using a specific oxygen transfer efficiency, SOTE = 2 %/m OTE = SOTE x water depth = (2) (4.5) OTE = 9% 𝑂𝑇𝑅 Oxygen required = 𝑂𝑇𝐸 = (3412) ( 9 ) 100 Oxygen required = 37909 kg/day Calculating oxygen transfer correction factor: 𝑋 2 3 2 α = 1 − 0.16 (1000) = 1 − 4000 3 0.16 (1000) α = 0.56 Applying the transfer correction factor for wastewater: Oxygen required for waste = α x oxygen required Oxygen required for waste = (0.56)(37909) kg/day Oxygen required for waste = 21229 kg/day Using percentage of oxygen in the air = 20.95% ≈ 21% 𝑜𝑥𝑦𝑔𝑒𝑛 𝑟𝑒𝑞𝑢𝑖𝑟𝑒𝑑 Air required per tank = 𝑝𝑒𝑟𝑐𝑒𝑛𝑡𝑎𝑔𝑒 𝑜𝑓 𝑜𝑥𝑦𝑔𝑒𝑛 𝑖𝑛 𝑎𝑖𝑟 = (37909) ( 21 ) 100 Air required per tank = 180516 kg/m3 Air to be supplied = 𝐴𝑖𝑟 𝑟𝑒𝑞𝑢𝑖𝑟𝑒𝑑 𝑝𝑒𝑟 𝑡𝑎𝑛𝑘 𝑆𝐺𝑎𝑖𝑟,20 = (180516) 1 Air to be supplied = 180516 m3/ min Table 6 Bio-Reactor Design BIOREACTOR DESIGN Parameter Peak design flow, Q Flow per train, Q Flow per aeration tank, Q Mixed liquor suspended solids, X Volume per train, V Volume of sludeg returned, V Total Volume, V Total volume per tank, V Hydraulic retention time, θ Area of aeration tank, A Width of tank, W Length of tank, L Total depth of tank, d Value 68235 34118 8529 4000 17059 4265 21323 5331 0.16 1066 13 85 5 Units m3/d m3/d m3/d mg/L m3 m3 m3 m3 day m2 m m m BOD Loading Oxygen transfer rate, OTR Oxygen transfer efficiency, OTE 1705.875 3412 9 kg/m3 kg/day % Table 7 Bioreactor Design Cont'd BIOREACTOR DESIGN Parameter Value Oxygen required 37909 Oxygen transfer correction factor, 0.56 Oxygen required for wastewater 21229 Percentage of oxygen in air 21 Air required per tank 180516 Air to be supplied 180516 Assumed Parameters Number of aeration tanks 8 Number of trains 2 Number of aeration tanks per train 4 Food to mass ratio, F/M 0.1 Depth of tank, d 4.5 Freeboard, f 0.5 Width to depth ratio, W/d 2.5 Specific oxygen transfer efficiency, SOTE 2 BOD5 200 Percentage of sludge returned 25 Oxygen required to remove 1kg BOD 2 Specific gravity of air, SG 1 Units kg/day kg/day % kg/m3 m3/min m m %/m mg/L % kg - CLARIFIER The purpose of a clarifier is to effectively separate the solid waste, also know as sludge, from the water so that the water can be further treated and eventually released into the river channel. Circular clarifiers are commonly used in waste water treatment systems; however, they can also be rectangular in shape. Water can enter the clarifier either at the centre or around the periphery of the tank so as to not disturb the sludge that is already settling. The water that has entered the tank is detained for approximately 2 – 3 hours before it is allowed to leave the tank via overflow weirs located along the inside perimeter of the clarifier. This detention time may vary depending on parameters such as type of processes, surface loading rate, side water depth, design flow and recirculation rate. The base of the clarifier has an inverted cone shaped with a sludge hopper to allow the sludge to accumulate in one area where the it can then be easily removed from the tank. Rake arms slowly circulate at the base of the tank guiding the sludge to the hopper. The sludge accumulated at the cone shaped base is periodically emptied to prevent the sludge from floating to the surface due to lack of oxygen supply for extended periods of time. When the sludge is pumped out of the tank, a fraction of the sludge is wasted while the remainder is then reintroduced to the aeration tank. This treatment process minimizes the excess sludge that leaves the treatment facility. The wasted sludge is taken to an aerobic digestor for treatment before it can be removed from the system. In the design of the clarifiers for the town of Alexandria, a circular clarifier was chosen. Circular tanks are favoured because they require less maintenance, the drive bearings are not under wastewater, and the construction cost is generally lower than that for rectangular tanks, hence a circular tank was selected. CALCULATION: Number of clarifiers = 4 Flow into each clarifier: 𝑄𝑐,𝑖 = 𝑄 68235 = # 𝑜𝑓 𝑐𝑙𝑎𝑟𝑖𝑓𝑖𝑒𝑟𝑠 4 Qc,i = 17058.8 m3/d Using a maximum detention time, DTmax = 4 hours and a minimum detention time, DTmin = 2 hours Maximum volume for each clarifier: DTmax = 4 hours = 0.17days 𝑉𝑐,𝑚𝑎𝑥 = 𝐷𝑇𝑚𝑎𝑥 𝑄𝑐,𝑖 = (0.17)(17058.8 ) Vc,max = 2843.1 ≈ 2843 m3 Minimum Volume for each clarifier: DTmin = 2 hours = 0.08 days 𝑉𝑐,𝑚𝑖𝑛 = 𝐷𝑇𝑚𝑖𝑛 𝑄𝑐,𝑖 = (0.08)(68235) Vc,min = 1421.6 ≈ 1422 m3 Total Solids into each Clarifier: Assuming a re-circulation rate of 100% and X = 4000mg/L = 4,000,000 m3 TS = 2𝑄𝑐,𝑖 𝑋 = 2(17058.8)(4000000) TS= 136,470 kg/m3 Minimum Surface Area Required: Using a solid loading rate, SLR = 90kg/m2/d SAmin = 𝑇𝑜𝑡𝑎𝑙 𝑆𝑜𝑙𝑖𝑑𝑠 𝑆𝐿𝑅 = 136470 90 SAmin = 1516.3 ≈ 1517 𝑚2 Checking Discharge Overflow Rate: 𝑄 DOR = 𝑆𝐴 𝑐,𝑖 = 𝑚𝑖𝑛 17058.8 3033 𝑚3 DOR = 11.25 ≈ 11.3 𝑚2 ≤ 16 𝑚3 𝑚2 ∴ Discharge overflow rate okay Clarifier dimensions: Assuming a water depth, dc = 4.5 m and a freeboard, fc = 0.5 m Ac = 𝑉𝑐,𝑚𝑎𝑥 𝑑𝑐 +𝑓𝑐 = 2843 4.5+5 Ac = 568.6 m2 ≈ 570 m2 Ac = 2𝜋𝑟(𝑑𝑐 + 𝑓𝑐 ) + 𝜋𝑟 2 570 = (2)(3.142)𝑟(4.5 + 0.5) + (3.142)𝑟 2 Solving the above equation quadratically r = 9.34 m ≈ 10 𝑚 ∴ 𝑑 = 2𝑟 = 2(10) d = 20 m Table 8 Clarifier Design Parameters CLARIFIER DESIGN Design Parameters Value Peak flow rate, Q 68235 Flow rate per clarifier, Qc,i 17059 Maximum volume per clarifier, Vc,max 2843 Minimum volume per clarifier, Vc,min 1422 Total Solids, TS 136470 Minimum surface area required, SAmin 1517 Discharge overflow rate, DOR 11.3 Area of clarifier, Ac 570 Tank radius, r 10 Tank diameter, d 20 Assumed Parameters Number of clarifiers 4 Maximum detention time, DT 4 Minimum detention time, DT 2 Mixed liquor suspended solids, X 4000 Solid loading rate, SLR 90 Re-circulation rate 100 Water depth, dc 4.5 Freeboard, fc 0.5 Units m3/d m3/d m3 m3 kg/m3 m2 m3/ m2 m2 m m hours hours mg/L kg/m2/d % m m Figure 5 Drawing Showing Section through the Clarifier GRAVITY THICKENER This process applies gravity forces to separate the solids from the sludge, it reduces the sludge volume for handling and also reduces the operating cost of other processes. The sludge is pumped to a circular tank that comprises of a slow rotating rake, that breaks the junction between the sludge particles and increases settling and compaction, once thickened the volume of the sludge is reduced to approximately 90% of the original volume. Alexandria uses a gravity thickener for the volume reduction of sludge since the process consumes little energy and is one of the easiest methods for thickening. CALCULATION: To determine the daily primary solids produced: 𝐴𝑣𝑔. 𝑑𝑎𝑖𝑙𝑦 𝑓𝑙𝑜𝑤 𝑄𝑑 𝑥 𝑃𝑟𝑖𝑚𝑎𝑟𝑦 𝑖𝑛𝑓𝑙𝑢𝑒𝑛𝑡 𝑥 % 𝑜𝑓 𝑇𝑆𝑆 𝑟𝑒𝑚𝑜𝑣𝑒𝑑 22745 ∗ 240 ∗ 0.65 = 𝑔 1000 1000 𝑘𝑔 Ps = 3548.22 kg/d To determine Primary Sludge Volume: 𝑝𝑟𝑖𝑚𝑎𝑟𝑦 𝑠𝑜𝑙𝑖𝑑𝑠 3548.22 = 1000𝑘𝑔 1.01𝑥 0.05 𝑥 1000 𝑆. 𝐺 𝑥 % 𝑠𝑜𝑙𝑖𝑑𝑠 𝑥 𝑚3 Vp = 71 m3/ d To determine Gravity thickener tank volume: 𝑚3 𝑉𝑜𝑙. 𝑠𝑙𝑢𝑑𝑔𝑒 ( ) 𝑥 𝑟𝑒𝑡𝑒𝑛𝑠𝑖𝑜𝑛 𝑡𝑖𝑚𝑒 (ℎ𝑟) 71 𝑥 20 𝑑 = 24ℎ𝑟 𝑥 # 𝑜𝑓 𝑡𝑎𝑛𝑘𝑠 24 𝑥 1 VT = 60 m3 To determine Tank Area: 𝑉𝑜𝑙𝑢𝑚𝑒 (𝑉𝑡) 60 = 𝐻𝑒𝑖𝑔ℎ𝑡 𝑜𝑓 𝑊𝑎𝑡𝑒𝑟 3.5 A = 17m2 To determine Tank Diameter: √ 4 𝑥 𝐴𝑟𝑒𝑎 4 𝑥 17 = 𝜋 3.14 D = 4.64 m Check Retention time: Conditions: Retention time > 18 hrs 𝐷𝑖𝑎𝑚𝑒𝑡𝑒𝑟 2 𝑥 𝜋 𝑥 (𝐷𝑒𝑝𝑡ℎ 𝑜𝑓 𝑤𝑎𝑡𝑒𝑟 𝑥 # 𝑜𝑓 𝑡𝑎𝑛𝑘) 4.642 𝑥 𝜋 𝑥 3.5 = 71 𝑠𝑙𝑢𝑑𝑔𝑒 𝑣𝑜𝑙𝑢𝑚𝑒 (4 )𝑥 4 𝑥 (24) 24ℎ𝑟 R = 20 hrs Conditions Satisfied Gravity Tank Dimensions: 4.64 m Diameter x 4.0 m Depth Table 9 : Gravity Thickener Design GRAVITY THICKENER DESIGN Design Parameter Value Average Daily Flow, (Qd) 22745.10 Primary Influent TSS (Residential) 100 - 350 Primary settling tank % TSS removed 40 – 65 Primary Effluent % of Solids 3–7 Water Depth, (H) 3-4 Freeboard, f 0.5 Retention time, (R) R > 18 Specific Gravity, (S.G) 1.01 – 1.06 Assumed Parameter Primary Influent TSS 250 Primary Settling Tank % TSS removed 65 Primary Effluent % of Solids 5 Water Depth, (H) 3.5 Retention Time, (R) 20 Specific Gravity, (S.G) 1.01 Units m3/d mg/L % % m m Hrs mg/l % % m hrs AEROBIC DIGESTOR The aerobic digester stabilizes the primary and secondary sludge by converting organic sludge to carbon dioxide, ammonia, and water by use of aerobic bacteria. It reduces volatile solid, pathogens and offensive odour in a process called aeration. In the digestion process the contents are well mixed and requires air supply to maintain the dissolved oxygen (DO) surplus in the digester, in the extended aeration the microorganisms enter the endogenous stage which then reduces the biological degradable organic matter, the food supply are then depleted and the microorganisms begin consuming their own protoplasm, this oxidizes it to CO2, H2O and ammonia (NPTEL 2018, 2). As the digestion continues, the ammonia is then converted to nitrates and the bio-solids matter is reduced to organic matter and stable volatile solids. This method of stabilization is used for the Alexandria Wastewater treatment plant, as the aerobic digester can reduce the water content to about 90%. CALCULATION: Waste Activated Sludge (W.A.S) was found to be = 1909kg/d To determine Quantity of Sludge: 𝑊. 𝐴. 𝑆 1909 = 𝑠. 𝑔 𝑥 % 𝑠𝑜𝑙𝑖𝑑 𝑥 1000 𝑘𝑔/𝑚3 1.02 𝑥 0.025 𝑥 1000 Quantity of sludge = 121.9 m3/d To determine Sludge Age: Winter Conditions/ Rainy season = 900o.d /15oC = 60 days ………………….Controlling Factor Summer Condition/ Dry season = 6000 . d / 300 C = 20 days To determine the Digester volume using Controlling factor (winter): Influent suspended solids concentration (Xi): 1.5 % = 15000 mg/L Digester Suspended Solid concentration (X): Xi/ 0.75 = 15000/ 0.75 = 11250 mg/L Aerobic Tank Volume (V): 𝑉= 𝑄𝑖(𝑋𝑖 + 𝑌𝑆𝑖) 121.19 (11250 + 175) = 1 1 𝑋 (𝐾𝑑𝑃𝑣 + 𝜃𝑐 ) 11250 ((0.05 ∗ 0.8) + θc) V = 2852 m3 Where: Qi – Quantity of Sludge (m3/d) X – Digester SS conc. (mg/L) Xi - influent suspended solids concentration Kd – reaction rate constant (d-1) = 5% (mg/L) Pv – Volatile fraction of digester SS Y – Fraction of influent BOD5 (decimal) (decimal) = 0.8 Si – influent BOD5 (mg/L) θc – Solid retention time (d) = 60d To determine Dimensions for the digester: Number of Aerobic Digester Tank = 2 Volume of Aerobic Digester = 2852 m3 Volume for 1 Tank =2852/ 2 = 1426 m3 per tank Assuming a height of water = 4.5 m Assuming Freeboard = 0.5 m 4 𝑥 𝐴𝑟𝑒𝑎 D =√ 𝜋 = √ 4 𝑥 285.16 𝜋 D = 19.05 m Dimension of Aerobic Digester Tank: 19.05 m Diameter x 5 m Height (x 2 Tanks) Table 10 Aerobic Digestor Design AEROBIC DIGESTER DESIGN Design Parameter Specific Gravity Secondary Sludge Solid Content Volatile Solid Reduction Reaction rate Constant, (Kd) Minimum winter/ rainy temperature Maximum summer/ dry temperature Residence Time (Land Application) 9000 @ Residence Time (Land Application) 6000 @ Volatile Fraction of digester SS, (Pv) Influent Suspended Solid concentration, (Xi) SS concentration in digester % of influent SS Retention Time Value 1.02 – 1.06 0.5 – 2.5 40 – 50 0.5 - 0.14 15 25 15 30 0.8 0.5 - 2 75 40 – 60 Units % % d 0 C 0 C 0 C 0 C % % d Table 11 Aerobic Digestor Design AEROBIC DIGESTER DESIGN Assumed Parameter Specific Gravity Secondary Sludge Solid Content Volatile Solid Reduction Reaction rate Constant, (Kd) Minimum winter/ rainy temperature Maximum summer/ dry temperature Residence Time (Land Application) Residence Time (Land Application) Volatile Fraction of digester SS, (Pv) Influent Solid Concentration 9000 @ 6000 @ Value 1.02 2.5 45 0.5 15 30 15 30 0.8 1.5 Units % % d 0 C 0 C 0 C 0 C % Oxygen and Air requirement: To determine the VSS reduction: Total Mass of VSS: W.A.S x (VSS/TSS) = 1909/0.8 = 1527.02 kg/d VSS reduction: Total Mass of VSS * Volatile Solid reduction = 1909 * 0.8 = 858.95 kg/d To determine the oxygen required: Oxygen required = 2.3 kg O2/kg x VSS reduction = 858.95 x 2.3 Oxygen required = 1975.58 kg/d To determine the Volume of air required under standard condition: 𝑂𝑥𝑦𝑔𝑒𝑛 Volume of Air Required = 𝑀𝑎𝑠𝑠 𝑜𝑓 𝑎𝑖𝑟 𝑥 % 𝑂2 = 1975.58 1.2 𝑥 23.2% Volume of Air Required = 7096.18 m3/d To determine Total air required: Total Air Required = 𝐴𝑖𝑟 𝑟𝑒𝑞𝑢𝑖𝑟𝑒𝑑 𝑜𝑥𝑦𝑔𝑒𝑛 𝑡𝑟𝑎𝑛𝑠𝑓𝑒𝑟 𝑒𝑓𝑓𝑖𝑐𝑖𝑒𝑛𝑐𝑦 = 7096.18 0.06 Total Air Required = 118269.62 m3/d = 82.13 m3 / min To check diffused Air requirement: 𝑇𝑜𝑡𝑎𝑙 𝐴𝑖𝑟 Diffused Air Requirement = 𝑉𝑜𝑙𝑢𝑚𝑒 𝑜𝑓 𝑑𝑖𝑔𝑒𝑠𝑡𝑒𝑟 = 82.13 2851.57 Diffused Air Requirement = 28.8 L/ min. m3 Check regulations requirement: Condition: 25 – 35 L/ min. m3 Condition Satisfied Total Air Required for Digester: 28.8 L/ min. m3 Table 12 Aerobic Digestor Design AEROBIC DIGESTER DESIGN Design Parameter Value VSS/TSS 0.8 Percent of Oxygen 23.2 Mass of Air 1.2 Oxygen Requirement VSS Destroyed 2.3 Diffused Air requirement for W.A.S 23 -35 Assumed Parameter Oxygen Transfer Efficiency 6 Units % Kg/m3 O2/kg L/min. m3 % UV DISINFECTION Disinfection is a process that kills or inactivate pathogenic organisms such as bacteria, protozoans and viruses so that the effluent discharge does not cause harm to public health or the environment (Lin 2001, 688). Chlorine leaves a residual in the effluent after the disinfection process, this residual causes a chemical reactions with organic matter and forms disinfection by products (DBP) such as Trihalomethanes (THMs) which has been proven to be cancer causing agents (Pedersen 1997). Alexandria’s wastewater facility uses ultraviolet light for disinfection. UV has good germicidal qualities and is very effective in destroying microorganisms, the ultraviolet light disinfects water by making the pathogenic organism incapable of reproducing by disrupting the genetic material in the cell (Davis and Cornwell 2011, 304). In the process the effluent is exposed to the UV light for a period of time so that disinfection can occur and the wastewater must contain less than or equal to 30 mg/L of BOD and TSS (Spellman 2003, 615). Design Criteria: 1. Three –Bank System to be operated in series, with a capacity to meet average daily flow. 2. The UV units will be configured such that space for maintenance is adequate. 3. Maintenance Schedule will be implemented to ensure functionality of units 4. UV units will be horizontally configured. 5. Sensors will be installed to monitor the efficiency of the units. 6. Safety control system will be implemented to event of high lamp temperatures. CALCULATION: To determine Flow per channel Qc: Average daily Flow Qd (L/min) 15795.21 = # of channels 2 Qc = 7898 L/min To determine Number of lamps per channel: Number of Lamps = 𝐹𝑙𝑜𝑤 𝑝𝑒𝑟 𝑐ℎ𝑎𝑛𝑛𝑒𝑙 𝑄𝑐 𝑙𝑜𝑎𝑑𝑖𝑛𝑔 𝑟𝑎𝑡𝑒 = 7898 30 Number of Lamps = 263 lamps per channel To determine Number of lamps per bank: 𝑛𝑜.𝑜𝑓 𝑙𝑎𝑚𝑝𝑠 Number of Lamps = 𝑛𝑢𝑚𝑏𝑒𝑟 𝑜𝑓 𝑏𝑎𝑛𝑘𝑠 = 263 3 Number of Lamps = 88 lamps per bank Check for System configuration: Condition: hydraulic loading rate 20 – 80 L/lamp.min 𝐴𝑣𝑒𝑟𝑎𝑔𝑒 𝑑𝑎𝑖𝑙𝑦 𝑓𝑙𝑜𝑤 𝑄𝑑 7898 Hydraulic Loading Rate = 𝑚𝑜𝑑𝑖𝑓𝑖𝑒𝑑 𝑙𝑎𝑚𝑝 𝑥 𝑏𝑎𝑛𝑘 = 96 𝑥 3 Hydraulic Loading Rate = 27 L/ lamp. Min Condition Satisfied Table 13 Disinfection System Design DISINFECTION SYSTEM DESIGN Design Parameter Value Average Daily Flow (Qd) 22745.10 15795.21 Minimum transmittance 55 System head loss coefficient 1.8 Lamp / Sleeve diameter 23 Area of Quartz Sleeve 4.2 x 10-4 Lamp Spacing (center to center) 75 Minimum Design Dose 100 Hydraulic loading rate 20 – 80 Number of banks 3 Acceleration due to gravity 9.81 Assumed Parameter Number of Channels 2 Flow per channel 7898 Number of lamps per channel 263 Minimum number of lamps per bank 88 Lamp per module 16 Number of modules 6 Corrected Lamp per bank 96 Manufacturer check 27 Units m3/d L/min % mm m2 mm mJ/cm2 L/min.lamp Only m/s2 Only L/min Only Only Only Only Only L/lamp.min SLUDGE DRYING BED This uses a method that removes the water from the sludge naturally through percolation, gravity and evaporation, it requires land space and uses less operating energy than mechanical dewatering systems. The dewatering process removes moisture from the sludge after the sludge has been stabilized, it helps to reduce the overall cost of transportation to the disposal site since the dewatered sludge is easier to handle than the thick sludge or liquid sludge (Lin 2001, 786) . Paved decanting drying beds was selected for the Alexandria Town, despite the fact that it requires land space, it is less complex than mechanical systems and produces higher solid cake, and is advantageous in warm climates. The paved bed consists of a concrete or asphalt pavement above porous gravel sub-base with a slope of at least 15%. CALCULATION: Volume of Digested Sludge = 1909 kg/ d To determine Wet bio-solids = 1909 x 365 = 696785 kg/yr To determine Dry Solids = Wet bio-solids x % solid = 696785 x 0.06 = 41807.1 kg/ year Free water pan evaporation Re = 10 x ke x Ep = 10 x 0.6 x 120 = 720 Area: 1.04𝑆 [ 𝐴= 103 𝑘𝑔 1 − 𝑆𝐷 1 − 𝑆𝑒 − ]+( ) 𝑥 (𝑃)(𝐴) 𝑆𝐷 𝑠𝑒 𝑚3 𝑅𝑒 103 𝑘𝑔 1 − 0.08 1 − 0.35 1.04 𝑥 41807 [ 0.08 − ]+( ) 0.35 𝑚3 𝐴= 720 A = 583.70 / (1 – (103 x 0.6)/ 720) A = 3502.20 m3 = 0.35 ha Area of bed = 0.10 ha Number of Bed = 0.35 / 0.10 = 3.5 Number of Sludge Drying bed: 4 (four) Table 14 Sludge Drying Bed Design SLUDGE DRYING BED DESIGN Design Parameter Value Thickened Sludge 1909 Solids 6 Wet Bio-Solids 696785 Dry Bio- Solids 41807.1 Assumed Parameter Dry Solids in applied bio-solid (before decanting) 6 Dry solids in bio-solids (after Decanting) 8 Dry Solids for final disposal 35 Free water pan evaporation, Re 120 ke 0.6 Evaporation rate, Re 720 Area, A 0.35 Number of Beds to be used 4 Units kg/d % kg/yr Kg/yr % % % Cm/yr ha - SECURITY An important element in security systems is the use of closed-circuit television as a tool to assess the alarms triggered by exterior or interior intrusion sensors. CCTV systems can also provide recorded evidence for use in criminal courts or administrative procedures against employees. Closed-circuit television (CCTV) coverage on the area over the intake can help prove or disprove whether anyone attempted to place contaminants at that location. Cameras will be employed at the perimeter, at access control points, at critical operation locations, and on the interior of buildings. The resolution of the camera will dictate the quality of the image captured. The higher the resolution, the clearer the picture and the greater the ability to recognize or identify an intruder as a specific person so the tapes can be reviewed to disprove an allegation of wrong doings on the compound, thus helping to maintain the public's confidence in the utility. The first line of defence for a facility is at the perimeter. Barriers define the utility's borders and create a buffer zone with neighbouring property. The most common perimeter barrier is a chainlink fence. The fence delineates the boundary of the facility and whether it is a water treatment plant, finished water storage tank, or a booster pumping station. However, fences will keep out only the casual passer-by. A sturdy, well-maintained 7- to 8-ft galvanized chain-link fence will serve two purposes. First, a well-maintained, secure fence, topped by three strands of barbwire with at least a 20-ft clear zone on the outside of the fence line, may give an indication of the type of security an adversary may face. (American Water Works Association, 2005) The entrance of the Wastewater Treatment Plant is outfitted with a pedestrian gate to service the pedestrian traffic coming in to the facility; in addition to which there is a double swing gate to allow for vehicular traffic for vehicles as large as backhoes that may enter the compound to conduction maintenance on the facility. WORKER ACCOMMODATION Health, safety and welfare are basic requirements of any work place. Worker accommodation is important to ensure high moral and increase in good working conditions which directly improves productivity. Not providing adequate working conditions/correct health and safety practices is in breach of the General Duty Clause of the OSH Act. Upholding labour rights is not a costly procedure if done correctly from the beginning with sufficient staff time and documentation. However, when labour rights are not upheld the costs for resolving breaches can be considerable in the form of compensation, redoing work, hiring equipment for longer than anticipated, delays in schedule completions, and additional monitoring and due diligence. The workers area is equipped with a bathroom, kitchen, sickbay and a safety equipment storage room. Figure 6 Showing Plan view of Worker Accommodation Area LABORATORY LAB OCCUPATIONAL HEALTH OF SAFETY Adapted from Standard Methods for the Examination of Water and Wastewater Promptly flush eyes with water if chemicals get into them for a minimum of 15 minutes and seek immediate medical attention. Promptly flush affected area with water for approximately 15 minutes and remove any contaminated clothing. If symptoms persist after washing, seek medical attention. Promptly clean up spills, using appropriate protective apparel and equipment and proper disposal procedures. Do not smell or taste chemicals. Vent any apparatus that may discharge toxic chemicals into local exhaust devices. DO NOT eat, drink, smoke, chew gum, or apply cosmetics in areas where laboratory chemicals are present. Always wash hands before conducting these activities. Handle and store laboratory glassware with care to avoid damage. Use equipment for its designed purpose only. Wash areas of exposed skin well before leaving the laboratory. Do not use mouth suction for pipetting or starting a siphon. Remove laboratory coats immediately on significant contamination with hazardous materials. Confine long hair and loose clothing. Wear shoes at all times in the laboratory but do not wear sandals or perforated shoes. Keep work area clean and uncluttered, with chemicals and equipment properly labelled and stored. Clean up work area on completion of an operation or at the end of each day. Wear appropriate eye protection where chemicals are stored or handled. Wear appropriate gloves when the potential for contact with toxic chemicals exists. Inspect gloves before each use, wash them before removal, and replace periodically. Use appropriate respiratory equipment when engineering controls are unable to maintain air contaminant concentrations below the action levels. Water quality is very important as water is needed every day to sustain life as we know it on earth. It is absolutely necessary to study the physical, biological, chemical and microbiological characteristics of water when testing the water quality. It is of utmost importance to test the quality of water at different components of the waste water treatment plant to determine whether the plant is functioning as it should. Table 15 Testing Scheme COMPONENT Influent Effluent PARAMETER TESTED Flow Biochemical Oxygen Demand Total Suspended Solids Biochemical Oxygen Demand Total Suspended Solids Ammonia Phosphorus Dissolved Oxygen pH Faecal and Total Coliform SAMPLING LOCATION At Wet Well FREQUENCY OF MONITORING Daily Daily Daily Daily Daily Daily Daily Daily Daily Weekly Bioreactor Clarifier Backwash Filters Aerobic Digester UV Disinfection Total Suspended Solids Biochemical Oxygen Demand Total Suspended Solids Total Suspended Solids Total Volatile Suspended Solids Settleable Solids Flow Temperature Daily Weekly Daily Daily Daily Daily TESTS Total Suspended Solids (TSS) Total Suspended Solids measures the wastewater treatment plant’s efficiency with respect to effluent quality. Total suspended solids can be referred to as particles that do not dissolve in water and cannot be filtered during the wastewater treatment process. Suspended solids may account for the unpleasant odour as organic solids may be degrading anaerobically and releasing a smell. Table 16 Total Suspended Solids Test EQUIPMENT Analytical Balance Beaker Vacuum Pump Aluminium Dishes Drying Oven Desiccator Filter Paper Pipettes Graduated Cylinders CHEMICALS Distilled Water PROCEDURE 1. Weigh dry filter paper and Aluminium dishes. 2. Place filter disk on filtration apparatus and rinse with distilled water and suction to dryness. 3. Pour sample into beaker and slowly stir with magnetic stirrer. 4. Rinse sides of apparatus with distilled water and suction to dryness. 5. Transfer filter to aluminium dish and dry dish and filter in oven. 6. Remove after 1 hour and put to cool in desiccator for 20 minutes. 7. Record weight of dried filter and sample. Total Volatile Solids (TVS) Total volatile solids normally represents the amount of organic solids in water. It observes the quality of the sludge. Table 17 Total Volatile Solids Test EQUIPMENT Analytical Balance Drying Oven Desiccator Petri Dishes Muffle Furnace CHEMICALS PROCEDURE 1. Place sample and dry dish in the muffle furnace. 2. Burn samples for 1 hour. 3. Cool samples inside furnace until temperature is 100oC. 4. Transfer samples to desiccator and cool. 5.Weigh cooled samples. Settleable Solids (SS) Settleable Solids measures the volume of solids settling from the wastewater for a given time period. It measures the influent quality, show the settling behaviour of the wastewater and allows for estimation of sludge volume accumulation. Settleable solids consist of both organic and inorganic matter. Table 18 Settleable Solids Test EQUIPMENT Stirring Rod Stopwatch Imhoff cone & rack CHEMICALS PROCEDURE 1. Gentle agitate the sample. 2. Fill the Imhoff cone with the sample up to a sufficient mark. 3. Allow the sample to settle for 45mins them agitate by lifting and rotating the Imhoff cone. 4. Allow the sample to settle for a further 15 minutes. 5. Record the volume of solids in the Imhoff cone. Biochemical Oxygen Demand (BOD5) The Biochemical Oxygen Demand (BOD) is an estimate of the strength of industrial or domestic wastes in terms of the oxygen consumed by microorganisms and bacteria to decompose the organic matter present in the waste over a period of time. The BOD test is most commonly used to measure waste loading at treatment plants and in evaluating the efficiency of wastewater treatment. The higher the BOD, the more oxygen will be demanded from the waste to break down the organics. Table 19 Biochemical Oxygen Demand Test EQUIPMENT Pipettes Volumetric Flasks Cylinders Incubator Dissolved oxygen probe & meter Dissolved Oxygen bottles and sealing caps CHEMICALS Dilution Water PROCEDURE 1. Prepare dilution water. 2. Prepare seed source. 3. Add an appropriate volume of sample to the BOD bottle, add seed and fill with dilution water. 4. Measure initial dissolved oxygen. 5. Incubate for 5 days at 20 oC. 6. Measure final dissolved oxygen. Dissolved Oxygen (DO) Dissolved Oxygen (DO) is an indicator for the health of a water body as it measures the amount of dissolved oxygen in water and evaluates pollution concentration. If the temperature is too high, there will not be enough oxygen present in water. Also, excessive amounts of microorganism use dissolve oxygen and deplete it from water starving aquatic animals. Dissolved oxygen levels must be kept above 4.2 mg/L to sustain aquatic life. Table 20 Dissolved Oxygen Test EQUIPMENT Burette Pipettes Beakers Erlenmeyer Flasks BOD Bottles CHEMICALS Manganous Sulphate Alkaline Azide Iodide Starch Solution Sodium Thiosulphate Sulphuric Acid PROCEDURE 1. Fill BOD bottle with sample, remove any air bubbles and rinse bottle. 2. Add Manganous Sulphate to BOD bottle from the pipette. 3. Add Alkaline Azide Iodide to BOD bottle from the pipette. 4. Invert bottle to mix sample and reagents. 5. Allow sample to settle to half the volume, invert sample again and allow to settle again. 6. Add Sulphuric Acid to BOD bottle, cover and invert until floc disappears. 7. Transfer an appropriate amount of sample to a flask. 8. Use Sodium Thiosulphate to titrate the sample until the yellow colour disappears. 9. Add starch solution to sample, mix and continue titrating to colourless endpoint then record final burette volume. Total and Faecal Coliform Total coliforms are bacteria that are usually found in the environment. Faecal coliforms is a subgroup of bacteria of total coliforms that are considered to be present primarily in the intestines and faeces of warm-blooded animals. Origins of faecal coliforms are more identifiable than the origins of total coliform. Faecal coliforms are considered a more accurate indication of animal or human waste than the total coliforms. Faecal coliform colonies tend to be less than total coliform as it is diluted. Table 21 Total and Faecal Coliform Test EQUIPMENT Membrane Filters Pipettes Graduated Cylinders Incubator Forceps Funnels Water Bath Alcohol Burner Petri Dishes Filtration Apparatus Dilution Bottles CHEMICALS Dilution Water PROCEDURE 1. Place membrane filter on suction bed of filter funnel. 2. Add an appropriate volume of sample to measuring cylinder and top up with sterile water. 3. Pour contents into filter funnel to be suctioned. 4. Rinse cylinder and funnel with sterile water. 5. Suction membrane filter until dry. 6. Transfer dry filter to petri dish with forceps. 7. Incubate inverted petri dish for 16-24 hours. pH: pH is a measure of hydrogen ions present in a solution and is expressed as the negative log of H plus ions concentration. The pH scale runs from 1-14. Solutions that have a pH of less than 7 is considered to be acidic. Solutions that have a pH greater than 7 is considered to be alkaline. Solutions that have a pH of 7 is considered to be neutral. Table 22 pH Test EQUIPMENT pH metre with electrodes pH paper Beakers Thermometer Magnet CHEMICALS PROCEDURE Method 1 (Visual using pH paper): 1. Immerse pH paper into sample. 2. Match colour on paper to with scale of colours provided. 3. Record matched pH value. Distilled Water Method 2 (Electrometric using pH meter): 1. Rinse electrodes with distilled water. 2. Rinse beaker with some of sample and fill to a suitable volume. 3. Immerse electrode into sample. 4. Use magnet to slowly agitate sample and record pH after 5 minutes. Ammonia-Nitrogen In wastewater, phosphorous removal and nitrogen removal do not occur simultaneously. Nitrates appears to interfere with phosphorous uptake, and phosphorus will not be removed until the nitrate is gone. Table 23 Ammonia-Nitrogen Test EQUIPMENT CHEMICALS Pipettes Retort Stand Volumetric Flasks Sodium Hydroxide Sulphuric Acid PROCEDURE 1. Pour sample into Volumetric flask and dilute if necessary. 2. Add borate buffer to sample. 3. Adjust pH by adding sodium hydroxide. 4. Attach flask to distillation apparatus and distil. 5. Collect distillate in sulphuric acid. Phosphorus Phosphate present in water at a wastewater treatment plant is responsible for the growth of algae. The source of phosphates is detergents and excessive agricultural application of fertilizers. Phosphate removal requires true anaerobic conditions, which occur only when there is no other oxygen donor. Table 24 Phosphorus Test EQUIPMENT Spectrophotometer Filter photometer Acid-washed glassware CHEMICALS Sulphuric Acid Potassium antimonyl tartrate solution Ammonium molybdate solution Ascorbic acid Stock phosphate solution Standard phosphate solution Phenolphthalein indicator PROCEDURE 1. Pipet sample into volumetric flask. 2. Add combination of potassium antimonyl tartrate solution, ammonium molybdate solution, and ascorbic acid and mix thoroughly. 3. Measure absorbance after 30 min, using reagent blank as reference sample. TREATMENT PROCESSES Figure 7 Flow Chart Showing Wastewater Treatment Process SCREENING Screening is one of the first operations at the wastewater treatment plant. The screening device’s main function is to remove large object present in the wastewater. The performance of screens depends on the bar spacing. Screens can be cleaned by removing them manually or by the process of backwashing. It must be noted that the frequency of cleaning of the screens all depends on the quality of wastewater entering the plant. The screeners can be classified as follows: - Coarse Screens - Medium Screens - Fine Screens AERATED GRIT CHAMBER Grit Chamber is the next stage of the treatment process, this also forms the preliminary stage of treatment, it removes heavy inorganic material with specific gravity of 2.4 -2.7 such as sand, this process depends on gravity for sedimentation to occur. This stage of the treatment process is important as it prevents damage to the pumps and prevent inorganic particles from accumulating in the sludge digester. The aerated grit chamber consists of a spiral flow aeration tank, the grit settles to the bottom of the tank and the lighter organic particles are carried with the roll of the spiral motion (NPTEL 2018). PRIMARY TREATMENT PRIMARY SEDIMENTATION TANK This is the only primary treatment stage in the treatment process. The water is usually introduced peripherally into the tank. This stage involves the removal of particles from the water by means of settlement. The water in this stage may be detained for about 2 – 3 hours before it is taken to the secondary treatment process. SECONDARY TREATMENT BIOREACTOR This is the beginning of the secondary treatment process and is where aeration takes place. The water is pumped into the bioreactor/aeration tank where air is forced into the system through different aeration methods. In extended aeration treatment, sludge is measured, and a fraction is pumped back into the aeration tank to be reused in the treatment. The water in the tank may stay approximately 6 – 8 hours in the conventional treatment plant, but in the extended aeration process the water may stay in the tank at least 24 hours before it is then taken to the clarifier for sludge separation. CLARIFIER Water enters the secondary clarifier after it leaves the aeration tank so that the sludge can be separated from the water which is then further treated before it is discharged into the river channel. The clarifier mainly consists of a hopper, inlet, rake arm, skimming arm and effluent weir. The hopper is located to the base of the clarifier and is where the sludge is collected so that it can either be removed from the system or returned to the aeration tank for reuse. The inlet is located usually located to the centre of the clarifier so that the influent does not disturb the sludge that is already settling in the tank. The rake arm assists in guiding the sludge to the sludge hopper to be removed and the skimming arm removes sludge from the water surface. The effluent weir allows the treated water to be removed front the tank so that it can be further treated before discharge into the environment. AEROBIC DIGESTER This is the first stage of the secondary treatment process. The aerobic digester main purpose is to produce stable end product suitable for disposal, the process converts organic sludge solids to carbon dioxide, ammonia, and water by aerobic bacteria. In this process the sludge is introduced to the digester on a batch, semi batch or continuous basis, the design standard varies based on the sludge characteristics and method of disposal. The sludge is usually thickened before this process to aid in volume reduction of water content. DISINFECTION Disinfection is last process in wastewater treatment. Disinfection of water is done to kill any disease causing organisms present in the water after it undergoes primary and secondary treatment. Outbreaks that can occur as a result of untreated water are acute gastroenteritis, hepatitis shigellosis, ciardiasis, chemical poisoning, typhoid fever, and salmonellosis (Cheresmisinoff, 2002, 446). The use of ultraviolet light disinfects effluent by instantaneously neutralizing microorganism as they pass the submerged UV light, when microorganism are exposed to germicidal wavelengths the are rendered incapable of reproducing. This disinfection process is considered safer than the use of chlorination, it is cost effective and does not react with organic matter to form carcinogenic by products due to the by-products that are produced from chemical reactions with organic matter. UV is one of the safest cost effective method that does not react to form carcinogenic by-products (Trojan Technologies 2018). SLUDGE DRYING BED Sludge drying beds are used for sludge dewatering; sludge dewatering is separation of liquid and sludge solids. Sludge drying beds can be of two type, either open or covered. The Wastewater Treatment Plant of Alexandria Town utilizes the open sludge drying bed approach. Sludge from the wastewater treatment process is removed and spread as evenly as possible on the drying beds. The sludge is allowed to dry by a combination of evaporation and gravity filtration through the layered sand on which the sludge rests. The sludge beds consist of a bottom layer of graded gravel integrated with perforated pipes which supports a layer of coarse sand. The sludge takes 8-21 days to dry, this can vary with climatic conditions. Sludge that has been dried appears on the bed surface as cracked, it is bagged to be transported and sold as fertilizer for crops. Using dried sludge for agricultural purposes can be deem as recycling, therefore it is sustainable as it prevents pollution and generates funds that can do toward maintenance of the plant and facilities. LAYOUT OF WWTP Figure 8: Layout of WWTP for Alexandria CONCLUSION The wastewater treatment plant of Alexandria Town has proven to be successful as it allows disease-causing bacteria and viruses to be destroy, allowing the population of Alexandria Town to remain healthy citizens of Trinidad. The wastewater treatment plant is sustainable as it reduces pollutants from being emitted into the environment, and it is easier to maintain than conventional septic tanks systems as well as drainage field systems. The design wastewater treatment plant operates at a 90% efficiency and would continue to do so as the employees of the Alexandria Town operate with a strategic PLAN, DO, CHECK AND ACT action plan. REFERENCES Davis, Mackenzie L., and David A. Cornwell. 2011. Introduction to Environmental Engineering United States of America The McGraw- Hill Companies Dokuz University. 2018. “Wastewater Engineering”. Accessed November 18, 2018. http://web.deu.edu.tr/atiksu/ana52/abdtre08.html “CVNG 3007: Environmental Engineering I Laboratory Manual-The Analysis of Water and Wastewater.” Accessed October 26, 2018. http://myelearning.sta.uwi.edu/pluginfile.php/406452/mod_resource/content/1/Envi%20L aboratory%20Manual%2017-18.pdf Lagoon Online. 2015. “Fine Bubble Aeration”. Accessed November 21, 2018. http://www.lagoonsonline.com/fine.htm Lin, Shun Dar. 2001. Water and Wastewater Calculations Manual Edited by C.C Lee, Handbook of Environmental Engineering Calculations United States of America McGraw-Hill Meteorological Office of Trinidad and Tobago. 2018. “Climate”. Accessed November 20, 2018. https://www.metoffice.gov.tt/Climate NPTEL. 2018. "Sludge Management ". NPTEL IIT Kharagpur accessed November 20, 2018. https://nptel.ac.in/courses/105105048/M22L37.pdf. Pedersen, T.L. 1997. "The Effects of Chlorination and Chlorine on Drinking Water ", accessed November 21, 2018. http://extoxnet.orst.edu/faqs/safedrink/chlor.htm Qasim, Syed R., Wastewater Treatment Plant: Planning, Design and Operation. 2nd ed. USA: CRS Press, 1999. Red Valve Company. 2002. “Aeration System design for loading peak loadings” Accessed November 23, 2018. http://web.deu.edu.tr/atiksu/ana52/redvalve.pdf Rice, E.W., R.B. Baird, A.D. Eaton, L.S. Clesceri, “Standard Methods for the Examination of Water and Wastewater”. 22nd ed. USA: American Public Health Association, American Water Works Association, Water Environment Federation, 2012. Spellman, Frank R. 2003. Handbook of Water & Wastewater Treatment Plant Operations. United States of America Lewis Publishers Water Quality Solution. 2018. “Fine Bubble vs Coarse Bubble Diffusion”. Accessed November 22, 2018. https://waterqualitysolutions.com.au/fine-bubble-vscoarse-bubble-diffusion/ APPENDICES Table 25 Average Domestic Dry Weather Flows for Alexandria DOMESTIC FLOWS Facility Residential Houses Apartments No. of Facilities Description No. of Person per Facility Consumption (lpd) Total Consumption (lpd) Average Flow (m3/d) Domestic Population 4000 Persons 4 280 4480000 4480 16000 1800 Persons 4 280 2016000 2016 7200 6496 23200 Total Table 26 Average Commercial Dry Weather Flows for Alexandria COMMERCIAL FLOWS Facility Hotel Mall Theatre Post Office Supermarket Elderly Home Guest House Coffee Shop Gas Station Bank Restaurant Bar Total No. of Facilities Description No. of Person per facility Consumption (lpd) Total Consumption (lpd) Average Flow (m3/d) Commercial Population 2 2 2 Guest Employee Parking Spaces 200 450 300 190 4 4 76000 3600 2400 76 3.6 2.4 400 900 600 2 Employees 300 40 24000 24 600 2 2 Toilet Room Seat 20 200 2000 12 80000 4800 80 4.8 40 400 1 2 2 Employee Toilet Room Employee 60 20 10 55 2000 40 3300 80000 800 3.3 80 0.8 60 40 20 2 Resident 55 421 46310 46.31 110 2 4 Employee Person 70 120 48 200 6720 96000 6.72 96 140 480 2 2 2 2 3 6 4 Customer Employee Vehicles Served Employee Employee Meal Customer 100 15 300 20 100 150 50 24 48 40 50 55 10 8 4800 1440 24000 2000 16500 9000 1600 4.8 1.44 24 2 16.5 9 1.6 200 30 600 40 300 900 200 4 Employee 20 50 4000 4 80 487.27 6140 Table 27 Average Institutional Dry Weather Flows for Alexandria INSTITUTIONAL FLOWS Facility No. of Facilities Description No. of Person per facility Consumption (lpd) Total Consumption (lpd) Average Flow (m3/d) Institutional Population 2 2 2 2 3 3 Students Employees Student Employees Student Employees 200 275 250 60 600 100 72 55 72 55 96 55 28800 30250 36000 6600 172800 16500 28.8 30.25 36 6.6 172.8 16.5 400 550 500 120 1800 300 2 2 1 1 2 2 Employees Employees Bed Employee Employee Seats 25 25 300 250 25 45 55 55 78.2 48 48 50 2750 2750 23460 12000 2400 4500 2.75 2.75 23.46 12 2.4 4.5 50 50 300 250 50 90 3 Seats 150 42 18900 18.9 450 2 Persons 500 144 144000 144 1000 501.71 5910 ECC Primary School Secondary School Police Station Fire Station Hospital Health Centre Church Recreational Area Total Table 28 Projected Design Flows for Alexandria Town for 2018 - 2038 PROJECTED FLOWS Year Dry Weather Flow (m3/d) Wet Weather Flow (m3/d) Total Average Flow (m3/d) Total Peak Flow (m3/d) 2018 2023 2028 7485 7859 8252 11227 11789 12378 18712 19648 20630 56137 58944 61891 2033 8665 12997 21662 64986 2038 9098 13647 22745 68235 1.5 Growth Factor Table 29 Population Distribution Percentage Table 30 Population Growth for Year 2038 FLOW CATEGORY POPULATION NUMBER Domestic 23200 POPULATION (%) 66 Commercial 6140 17 Institutional 5910 17 Total Population 35250 100 FUTURE POPULATION Parameter Value Units P 35250 - r 5 % t 20 years Pi 89075 - Figure 9: Water pollution rules parameters