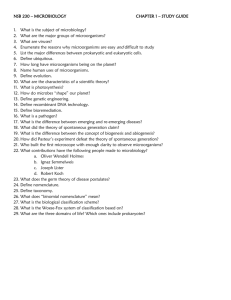

Chapter 4 – Control of Microorganisms MLAB 2434 –MICROBIOLOGY KERI BROPHY-MARTINEZ

advertisement

MLAB 2434 –MICROBIOLOGY KERI BROPHY-MARTINEZ Chapter 4 – Control of Microorganisms Control of Microorganisms (cont’d) Sterilization vs. Disinfectant Sterilization • Removes all forms of life, including spores • “All or nothing” process • Chemical or physical Control of Microorganisms (cont’d) Disinfection • Removes all pathogenic organisms but not necessarily all spores • “Disinfectants” are chemicals applied to inanimate objects • “Antiseptics” are disinfectants applied to living tissue. They do not kill spores. Control of Microorganisms (cont’d) Factors Influencing Degree of Killing Types of organisms - Bacterial spores, mycobacteria, nonlipid viruses, fungi, bacteria, lipid viruses (most resistant to least resistant) Control of Microorganisms (cont’d) Number of organisms – microbial load • The higher the number of organisms, more exposure to the killing agent is required. Concentration of disinfecting agent Presence of organic material • Affects killing activity by inactivating disinfecting agent Nature of the surface to be disinfected Contact time Temperature Control of Microorganisms (cont’d) Methods of Disinfection & Sterilization Physical Methods: mainly for sterilization • Moist Heat – autoclave = 15 psi at 121° C for 15 minutes • Dry Heat- 1.5-3 hours @ 160- 180o • Bacticinerator • Hot air ovens ( glassware) • Boiling & pasteurization • Do NOT sterilize or remove spores Control of Microorganisms (cont’d) • Radiation: used to sterilize disposable medical supplies (catheters, syringes) • Filtration • Liquids: liquid is pulled through cellulose acetate or cellulose nitrate membrane with a vacuum. Used for heat sensitive liquids such as serum, antibiotic solutions, toxic chemicals and vaccines • Air: use high-efficiency-particulate air (HEPA) filters. Designed to remove organisms larger than 0.3 µm from isolation rooms, biological cabinets and respirators Control of Microorganisms Quality control for Sterilization Procedures For each load: • Temperature & duration of cycle should be checked and recorded • Indicator tape is attached to each item Weekly: • Check biological indicators • Bacterial spores are used as indicator of sterilization • Sporestrips are placed in the center of the load to be sterilized. After the cycle, the strips are cultured to demonstrate complete kill. • Spores used • Bacillus stearothermophilusmoist steam • Bacillus subtilis- dry heat Control of Microorganisms Chemical Methods: used in disinfection Control of Microorganisms (cont’d) Microbiology Laboratory Safety Program Address biological hazards Describe safe handling, storage and disposal of biological hazards & chemicals • MSDS: Material Safety Data Sheets • Biohazard bags & sharps containers Correct techniques for lifting and moving heavy objects Procedures in event of fire, natural disasters, and bomb threats • Fires: R= rescue A= alarm C= contain E=extinguish • Electrical: grounded 3-pronged plugs, check for frayed cords Control of Microorganisms (cont’d) Occupational Safety and Health Administration (OSHA) Safety training for potentially exposed employees Goal is to protect workers Control of Microorganisms (cont’d) Exposure Control Plan Required by OSHA • Determine tasks that may result in hazards • A plan to investigate exposure and prevent reoccurrences • Methods of compliance with universal precautions • Engineering and work practice controls • Personal protective equipment (PPE) • Workplace cleanliness • Handling and disposal of waste • Active hazard training programs Control of Microorganisms (cont’d) Universal/standard precautions Developed in 1985, redone in 1996 All blood and body fluids are treated as infectious • Lone exception is sweat Precautions address • Hand washing • Gloves, mask, eye protection • Lab coats • Appropriate sharps disposal • Environmental controls • Employers are required to provide appropriate PPE Control of Microorganisms (cont’d) Engineering controls Controls designed to remove hazards from the workplace • Some examples are eye wash stations, safety showers, eye shields Control of Microorganisms (cont’d) Handling Biological Hazards Two sources of hazards: • Patient specimens • Actively growing cultures of microorganisms Control of Microorganisms (cont’d) Biosafety levels (BSL) BSL-1 • Well classified and not known to cause disease • Standard PPE BSL-2 • Moderate potential hazard • PPE and BSC class I Control of Microorganisms (cont’d) BSL-3 • Potential aerosol transmission • Agents may have serious lethal consequences • PPE, BSC Class II or III, negative-pressure rooms BSL-4 • Dangerous and exotic pathogens • PPE, BSC Class III, negative-pressure rooms • Decontamination of room and personnel after use Control of Microorganisms (cont’d) Safety Cabinets (Hoods) Class I – exhaust fan moves the air inward through the open front. Air passes through HEPA filter. Example = chemical fume hood Class II – air pulled inward and downward and then passes through HEPA filter before reaching work surface. Example = most common microbiology laboratory hood Control of Microorganisms (cont’d) Class III Self-contained, ventilated system for highly infectious microorganisms Provides highest level of personal protection Closed front contains attached gloves for work on bench Safety Cabinets (Hoods) References Engelkirk, P., & Duben-Engelkirk, J. (2008). Laboratory Diagnosis of Infectious Diseases: Essentials of Diagnostic Microbiology . Baltimore, MD: Lippincott Williams and Wilkins. http://www.diytrade.com/china/4/products/3957592/EO_Gas_Indicator_ta pe.html http://www.fishersci.com/ecomm/servlet/fsproductdetail?catalogId=1&productId=664041&langId=1&storeId=10652&distype=2&isChemical=false&fromSearch=0 Mahon, C. R., Lehman, D. C., & Manuselis, G. (2011). Textbook of Diagnostic Microbiology (4th ed.). Maryland Heights, MO: Saunders.