NZQA unit standard 8408 version 9

advertisement

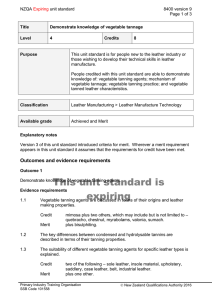

NZQA Expiring unit standard 8408 version 9 Page 1 of 3 Title Demonstrate knowledge of measurements used in leather manufacture Level 3 Purpose Credits 4 This unit standard is for people new to the leather industry or those wishing to develop their technical skills in leather manufacture. People credited with this unit standard are able to demonstrate knowledge of: measurement of hide and skin raw material characteristics; the measurements used for process control in leather manufacturing; and the measurements used to define finished leather properties. Classification Leather Manufacturing > Leather Manufacture Technology Available grade Achieved and Merit Explanatory notes Version 3 of this unit standard introduced criteria for merit. Wherever a merit requirement appears in this unit standard it assumes that the requirements for credit have been met. Outcomes and evidence requirements This unit standard is Demonstrate knowledge of the measurement of hide and skin raw material characteristics. expiring Evidence requirements Outcome 1 1.1 Measurements and units used to define the condition and characteristics of untanned hides and skins are described in relation to specified raw materials. Credit Merit 1.2 three of the following – weight, thickness, area, moisture content, temperature, degree of preservation. plus one other. Instruments for measurement of raw hide and skin characteristics are described in terms of their principle components, operating principles and methods of use. Credit Merit two of the following – area measuring machine, thickness gauge, moisture meter, dipslides. plus one other. New Zealand Industry Training Organisation SSB Code 101541 New Zealand Qualifications Authority 2016 NZQA Expiring unit standard 8408 version 9 Page 2 of 3 Outcome 2 Demonstrate knowledge of the measurements used for process control in leather manufacturing. Evidence requirements 2.1 Measurements used in tannery process control are described with reference to example applications. Credit Merit 2.2 Instruments for leather process control measurement are described in terms of their principle components, operating principles and methods of use. Credit Merit 2.3 four of the following – load weight, float length, pH, temperature, specific gravity, and relative humidity. plus one other. three of the following – load cell, flow meter, pH meter, hydrometer, hygrometer. plus two others. Chemical test indicators are described in relation to their use in leather process control. Credit Merit two of the following – deliming, pickling, neutralisation, syntanning. plus one other. Outcome 3 Demonstrate knowledge of the measurements used to define finished leather properties. This unit standard is expiring Credit three measurements for each of three of the following – upper, Evidence requirements 3.1 Measurements used to define finished leather properties are described for different specified leather types. Merit 3.2 clothing, chamois, sole, woolskin, belt, upholstery. plus one leather type. Instruments for measurement of finished leather properties are described in terms of their principle components, operating principles and methods of use. Credit Merit three of the following – colour computer, tensometer, lastometer, rub tester, soxhlet apparatus, flexometer or any other. plus one other. Replacement information This unit standard has been replaced by unit standard 27897. New Zealand Industry Training Organisation SSB Code 101541 New Zealand Qualifications Authority 2016 NZQA Expiring unit standard 8408 version 9 Page 3 of 3 This unit standard is expiring. Assessment against the standard must take place by the last date for assessment set out below. Status information and last date for assessment for superseded versions Process Version Date Last Date for Assessment Registration 1 24 September 1996 31 December 2015 Revision 2 23 March 1999 31 December 2015 Review 3 27 April 2000 31 December 2015 Revision 4 20 February 2002 31 December 2015 Revision 5 14 October 2004 31 December 2015 Review 6 14 December 2007 31 December 2015 Review 7 21 February 2013 31 December 2015 Rollover 8 20 March 2015 31 December 2017 Rollover 9 17 September 2015 31 December 2018 Consent and Moderation Requirements (CMR) reference 0185 This CMR can be accessed at http://www.nzqa.govt.nz/framework/search/index.do. Please note Providers must be granted consent to assess against standards (accredited) by NZQA, before they can report credits from assessment against unit standards or deliver courses of study leading to that assessment. Industry Training Organisations must be granted consent to assess against standards by NZQA before they can register credits from assessment against unit standards. This unit standard is expiring Requirements for consent to assess and an outline of the moderation system that applies Providers and Industry Training Organisations, which have been granted consent and which are assessing against unit standards must engage with the moderation system that applies to those standards. to this standard are outlined in the Consent and Moderation Requirements (CMR). The CMR also includes useful information about special requirements for organisations wishing to develop education and training programmes, such as minimum qualifications for tutors and assessors, and special resource requirements. New Zealand Industry Training Organisation SSB Code 101541 New Zealand Qualifications Authority 2016