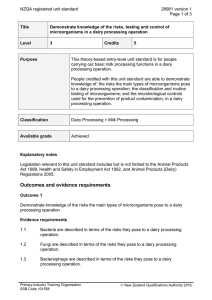

NZQA unit standard 16301 version 5

advertisement

NZQA Expiring unit standard 16301 version 5 Page 1 of 4 Title Explain microbiological sampling, testing methods and prevention of contamination in dairy products Level 4 Credits 4 Purpose People credited with this unit standard are able to explain: inprocess and final product microbiological sampling of dairy products; guidelines for laboratory accreditation for microbiological testing of dairy products; the enumeration of microorganisms; the isolation and identification of microorganisms; the influence of milk quality on product quality; and the prevention of the growth and survival of microorganisms during dairy processing. Classification Dairy Manufacturing > Dairy Product Safety and Risk Management Available grade Achieved Explanatory notes Definition Laboratory accreditation in this unit standard refers to the programme for the accreditation of New Zealand dairy industry and associated testing laboratories that has been developed by Telarc SAI and Ministry of Agriculture and Forestry. Outcomes and evidence requirements Outcome 1 Explain in-process and final product microbiological sampling of dairy products. Evidence requirements 1.1 In-process and final product microbiological sampling of dairy products is explained in terms of controls for aseptic sampling. Range people, environment, sampling equipment, replicate samples, sample protection. 1.2 In-process and final product microbiological sampling of dairy products is explained in terms of requirements for assuring comprehensive results. 1.3 In-process and final product microbiological sampling of dairy products is explained in terms of restrictions on re-sampling and re-testing of final dairy products. Primary Industry Training Organisation SSB Code 101558 New Zealand Qualifications Authority 2016 NZQA Expiring unit standard 16301 version 5 Page 2 of 4 Outcome 2 Explain guidelines for laboratory accreditation for microbiological testing of dairy products. Evidence requirements 2.1 Guidelines for laboratory accreditation for microbiological testing of dairy products are explained in terms of the identification of activities for which registration is granted. 2.2 Guidelines for laboratory accreditation for microbiological testing of dairy products are explained in terms of participation in inter-laboratory comparisons. 2.3 Guidelines for laboratory accreditation for microbiological testing of dairy products are explained in terms of quality controls required for laboratory accreditation. Outcome 3 Explain the enumeration of microorganisms. Evidence requirements 3.1 The enumeration of microorganisms is explained in terms of the production of a homogenous dilution of the product from which the maximum number of microorganisms can be isolated. 3.2 The enumeration of microorganisms is explained in terms of the procedure for plating of microorganisms in, or on, nutrient agar. 3.3 The enumeration of microorganisms is explained in terms of temperature and time requirements for incubation of agar plates. 3.4 The enumeration of microorganisms is explained in terms of requirements for expression and recording of colony counts. Outcome 4 Explain the isolation and identification of microorganisms. Evidence requirements 4.1 The isolation and identification of microorganisms are explained in terms of the use of appropriate media for identification of particular genera and species of microorganisms. 4.2 The isolation and identification of microorganisms are explained in terms of the use of enrichment where there are too few microorganisms to enumerate by plate counting. Primary Industry Training Organisation SSB Code 101558 New Zealand Qualifications Authority 2016 NZQA Expiring unit standard 4.3 16301 version 5 Page 3 of 4 The isolation and identification of microorganisms are explained in terms of tentative identification using the gram stain and catalase test. Outcome 5 Explain the influence of milk quality on product quality. Evidence requirements 5.1 The influence of milk quality on product quality is explained in terms of bacterial count levels that will cause measurable changes in pH. 5.2 The influence of milk quality on product quality is explained in terms of how psychrotrophic microorganisms may influence product quality. 5.3 The influence of milk quality on product quality is explained in terms of how lactic acid bacteria and coliforms may influence the pH of milk. 5.4 The influence of milk quality on product quality is explained in terms of the influence of thermoduric microorganisms on the quality of dairy products. 5.5 The influence of milk quality on product quality is explained in terms of the influence of somatic cells on final product quality. Outcome 6 Explain the prevention of the growth and survival of microorganisms during dairy processing. Evidence requirements 6.1 The prevention of the growth and survival of microorganisms during dairy processing is explained in terms of conditions required for growth and survival of environmental microorganisms. Range 6.2 The prevention of the growth and survival of microorganisms during dairy processing is explained in terms of conditions required for growth and survival of in-process microorganisms. Range 6.3 airborne microorganisms, water borne microorganisms, vermin and faecal carried microorganisms. mesophiles, thermophiles, non-starter lactic acid bacteria. The prevention of the growth and survival of microorganisms during dairy processing is explained in terms of the use of microbiological in-process trend data and process information to prevent and resolve microbiological problems. This unit standard is expiring. Assessment against the standard must take place by the last date for assessment set out below. Primary Industry Training Organisation SSB Code 101558 New Zealand Qualifications Authority 2016 NZQA Expiring unit standard 16301 version 5 Page 4 of 4 Status information and last date for assessment for superseded versions Process Version Date Last Date for Assessment Registration 1 5 July 1999 31 December 2017 Revision 2 13 June 2003 31 December 2017 Rollover and Revision 3 17 July 2009 Review 4 15 October 2015 31 December 2017 Rollover 5 21 January 2016 31 December 2019 31 December 2017 Consent and Moderation Requirements (CMR) reference 0022 This CMR can be accessed at http://www.nzqa.govt.nz/framework/search/index.do. Please note Providers must be granted consent to assess against standards (accredited) by NZQA, before they can report credits from assessment against unit standards or deliver courses of study leading to that assessment. Industry Training Organisations must be granted consent to assess against standards by NZQA before they can register credits from assessment against unit standards. Providers and Industry Training Organisations, which have been granted consent and which are assessing against unit standards must engage with the moderation system that applies to those standards. Requirements for consent to assess and an outline of the moderation system that applies to this standard are outlined in the CMR. The CMR also includes useful information about special requirements for organisations wishing to develop education and training programmes, such as minimum qualifications for tutors and assessors, and special resource requirements. Primary Industry Training Organisation SSB Code 101558 New Zealand Qualifications Authority 2016