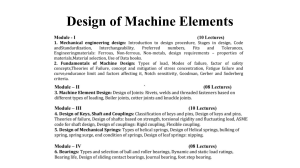

ENGR 2 Assignment 8 Due: Next Saturday, 9:50AM

advertisement

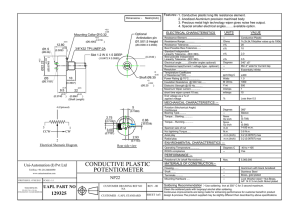

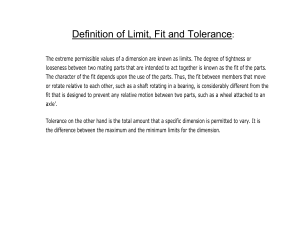

ENGR 2 Assignment 8 Due: Next Saturday, 9:50AM Chapter 9: 11a-c, 12a,b,d In one File Ch10: 1-4 all in one file, 15 9-11 Just do A-C, using the table following USE This tables for 9-11 build this table and 9-12 table in same file, Ex9-11and12.dwg use Table command Partial solution to Ex9-11 Ex 9-12 A, B, D Partial Solution to Ex9-12 Tables for 9-12 (all numbers except nominal size range are in thousandths of an inch) Ex 10-1 thru 10-4 put all in a single file Ex10-1to4.dwg. For 3 and 4 just type in answers in file See pp403-409 the straigtness tolerance is added using QuickLeader on p409 For 10-3 we calculate the maximum shaft size by adding the largest feature tolerance of +.04 with the straightness tolerance 0.003 at MMC This makes a “virtual” shaft diameter of 24.07 (it’s really only 24.004 but it could wobble by 0.003) The smallest hole to fit perfectly would be 24.07. However we want clearance of .02 so minimum size is 24.09. The max size would add the hole tolerance of .6 to that. 10-15 similar to GDT_Demo Right side dimension chopped off is height of 10 Surface 1 label is near crease