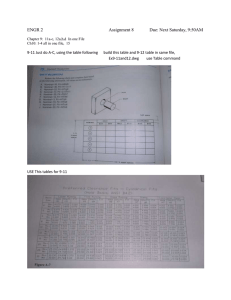

Limits, FITS AND TOLERANCES Due to the inevitable inaccuracy of manufacturing methods, a part cannot be made precisely to a given dimension. The permissible variation on the size is called tolerance. The two extreme permissible sizes on the actual size are called limits. When two parts are to be assembled, the relation resulting from the difference between their sizes before assembly is called a fit. 1 FIT - Condition of looseness or tightness between two mating parts being assembled together. 2 HOLE SHAFT Max Hole size – Basic Size = Upper Deviation Min Hole size – Basic Size = Lower Deviation Max shaft size – Basic Size = Upper Deviation Min shaft size – Basic Size = Lower Deviation CLEARANCE FIT Maximum shaft dimension < Minimum hole dimension INTERFERANCE FIT Maximum Hole size < Minimum Shaft size 5 TRANSITION FIT Obtained by overlapping of tolerance zones of shaft and hole …… Does not guarantee neither clearance nor interference fit. To obtain different types of fits, it is practice to vary tolerance zone of one of the mating parts HOLE BASED SYSTEM Size of hole is kept constant, shaft size is varied to get different fits. SHAFT BASED SYSTEM Size of shaft is kept constant, hole size is varied to get different fits. 7 Representation of Fit A fit is indicated by the basic size common to both components, followed by symbol corresponding to each component, the hole being quoted first. E.g. 45 H8/g7 8 9 10 Fundamental Deviations on Shaft Size 11 12 The selection of letter freezes one limit of hole / shaft Representation of Tolerance 1) Letter Symbol H : lower deviation of hole is zero h : upper deviation of shaft is zero 13 2) Number or Grade (ITG) = IT01, IT0, IT1,….IT16 gives the tolerance value (T). Units in μm 14 i = 15 The selection of Tolerance grade number freezes the other limit of hole / shaft Representation of Tolerance 1) Letter Symbol H : lower deviation of hole is zero h : upper deviation of shaft is zero 16 Representation of Fit Together (Letter & Grade) on both mating components decide quality of fit 0.021 INTERFERENCE FIT 0.022 0.013 Φ30.021 Φ30.035 Φ30.022 Φ30.000 H7 : Tol Grade 7 mean 21μ variation (H means upper deviation zero) p6 : Tol Grade 6 means 13μ variation (p means upper deviation is 22 μ) 17 FITS APPLICATIONS 19 20 Unilateral and Bilateral Tolerances 21 Compound Tolerance 60 ± 0.02 40 ± ??? 0.08 100 ± 0.06 22 Accumulation of Tolerances 23 Progressive Dimensioning 24 Limit Gauges The term ‘limit gauges’ signifies the use of gauges for checking the limits of the components. GO gauge checks Maximum Material Limit (MML) GO and NOT GO limits of plug gauge 25 26 Limit gauges ensure that the components lie within the permissible limits, but they do not determine the actual size or dimensions. GO and NOT GO limits of snap gauge 27 28 Taylor’s Principle Taylor’s principle states that the GO gauge is designed to check maximum metal conditions, that is, LLH and HLS. GO gauge can be designed to check more than one dimension at a time. NOT GO gauge is designed to check minimum metal conditions, that is, HLH and LLS. NOT GO gauge should check only one dimension at a time. 29 Gauge Tolerance: Normal practice is to take gauge tolerance as 10% of the work tolerance. Component that is manufactured outside the limits should not be accepted by gauges. Component rejected by the GO gauge can be reworked to maintain the limits because GO gauge checks maximum material limit. Component rejected by the NOT GO gauge is permanently rejected because NOT GO gauge checks minimum material limit. Hence close gauge tolerances will be provided on NOT GO gauges. 30