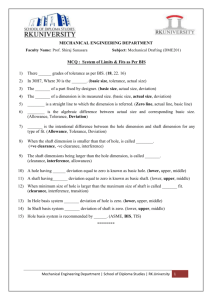

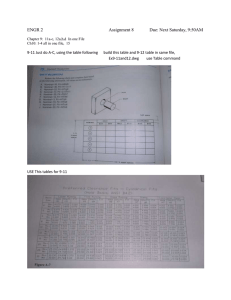

Design of Machine Elements References Machine design? & Objectives Def.:-Machine design is an area of study in which one learns to design machine parts by utilizing its whole knowledge and experience in field of mechanical engineering. OBJECTIVES OF DESIGN DESIGN FOR STRENGTH- safety is first so part to be designed should strong enough to withstand forces in its service. It also required to be resist some probable happening during service due to increased load by some reason. DESIGN FOR FUNCTION- every part in a machine has its own function for which it is applied in machine. designer should ensure that the part to be designed should fulfill its function satisfactory. DESIGN FOR MANUFACTURING PROCESS- Designer have to modify its product in the light of available manufacturing processes and their limitations and strengths. Design of machined part is generally different from that of casting etc. DESIGN FOR SAFETY- designer should ensure that the part he is designing should safe in use and any life or health hazard will not produce from its working. DESIGN FOR LOOK AND COMFORT- It is a secondary priority of designer to make a part with high level of comfort for user and also looks good. Introduction • Design is essentially a decision-making process. If we have a problem, we need to design a solution. • In other words, to design is to formulate a plan to satisfy a particular need and to create something with a physical reality. • Example:- to design of a chair, a number of factors need be considered (a) The purpose for which the chair is to be designed such as whether it is to be used as an comfort chair, an office chair or to accompany a dining table. (b) Whether the chair is to be designed for a senior citizen person or a child. (c) Material for the chair, its strength and cost need to be determined. (d) Finally, the aesthetics of the designed chair. Almost everyone is involved in design, in one way or the other, in our daily lives because problems are posed and they need to be solved. General procedure in machine design omitted Fig.- Stages in design Types of Design 1. 2. 3. Adaptive design (e.g.- Conveyor belts, control system of machines and mechanisms) Development design (e.g.- A new model of a car is a typical example of a developmental design) New/creative design (e.g.- A small vehicle for transportation of men and material on board a ship or in a desert.) Based on methods; a. Rational design b. Empirical design c. Industrial design (These are based on industrial considerations and norms viz. market survey, external look, production facilities, low cost, use of existing standard products. ) d. Optimum design e. CAD etc. Code and Standardization A code is a set of rules that serve as generally accepted guidelines recommended for the industry to follow. They exist for the purpose of safety, quality or other benefit. For example:- Electrical codes exist to ensure system reliability and that building occupants are safe from shock risks. A code is a set of rules and specifications for the correct methods and materials used in a certain product, building or process. Codes can be approved by local, state or federal governments and can carry the force of law. The main purpose of codes is to protect the public by setting up the minimum acceptable level of safety for buildings, products and processes. American National Standards Institute (ANSI) ANSI indexes ANSI, ISO, IEC and ASTM standards A technical standard is an established norm or requirement. It is usually a formal document that establishes uniform engineering or technical criteria, methods, processes and practices. Standards allow for interchangeability of parts, system interoperability, and they ensure quality, reliability and safety. Continued...... Interchangeability Interchangeability (computer science), the ability that an object can be replaced by another object without affecting code using the object. Interchangeable parts, the ability to select components for assembly at random and fit them together within proper tolerances. Why needed? The concept of interchangeability introduced into mass production at the beginning of the 20th century. In mass production, maintaining size of the component within a close degree of accuracy is difficult and timeconsuming. Even though there would be some variation. The reason for this inaccuracy may be due to errors in measuring, poor alignment of work piece, machining error, error due to tool wear, etc. The accuracy of component is important in proper functioning of mechanism, but it is useless to make parts such a precise to meet the practical requirement. Hence in mass production, it is allowed to the components have some variation in its dimension, within a certain limit. Continued...... The recognized variation in dimensions of components promotes the efficiency of manufacturing as well as make random mating parts fit properly. Whether the absolute interchangeability applicable or not, depends upon the form of different parts and tolerance adopted. In order to produce universally interchangeable parts, the manufacturing process, the gauges and cutting tools etc. must be standardized (international standards). The standard specification made possible by the development of gauges, measuring tools (e.g. caliper, sine bar), industry standards (e.g. screw threads), jigs and fixtures. Advantages Precise dimension is not essential, produce component within small dimension error limit. Economic oriented. It allows mass production, reduces the production cost. Mating parts can freely replace without custom fittings like fillets. Readily available replacement component in the market. Assembly process requires lesser skill. Reduce cost and labor time by allowing easy maintenance. Easy field repair. Preferred numbers • In industrial design, preferred numbers (also called preferred values or preferred series) are standard guidelines for choosing exact product dimensions within a given set of constraints. Product developers must choose numerous lengths, distances, diameters, volumes, and other characteristic quantities. While all of these choices are constrained by considerations of functionality, usability, compatibility, safety or cost, there usually remains considerable leeway in the exact choice for many dimensions. Preferred numbers serve two purposes: • Using them increases the probability of compatibility between objects designed at different times by different people. In other words, it is one tactic among many in standardization, whether within a company or within an industry, and it is usually desirable in industrial contexts. • They are chosen such that when a product is manufactured in many different sizes, these will end up roughly equally spaced on a logarithmic scale. They therefore help to minimize the number of different sizes that need to be manufactured or kept in stock. Continued...... Why Limit, fit and tolerances??? [Fig.- Aspects considered in design] Limit • The maximum and minimum permissible sizes within which the actual size of a component lies are called limits. • Limits are fixed with reference to the basic size of that dimension. • Upper limit (The high limit) for that dimension is the largest size permitted and the low limit is the smallest size permitted for that dimension. Continued...... [Fig.- Tolerance zones and fundamental deviation] Terminology • • • • • • • • • Zero Line: It is a line along which represents the basic size and zero (or initial point) for measurement of upper or lower deviations. Basic Size: It is the size with reference to which upper or lower limits of size are defined. Hole Designation: By upper case letters from A, B, … Z, Za, Zb, Zc (excluding I, L, O, Q, W and adding Js, Za, Zb, Zc) - 25 nos. Indian Stds. Shaft Designation: By lower case letters from a, b, … z, za, zb, zc (excluding i, l, o, q, w and adding js, za, zb, zc) - 25 nos. Upper Deviation: The algebraic difference between the maximum limit of size (of either hole or shaft) and the corresponding basic size, like ES, es. Lower Deviation: The algebraic difference between the minimum limit of size (of either hole or shaft) and the corresponding basic size, like EI, ei. Fundamental Deviation: It is one of the two deviations which is chosen to define the position of the tolerance zone. Tolerance: The algebraic difference between upper and lower deviations. It is an absolute value. Basic Shaft and Basic hole: The shafts and holes that have zero fundamental deviations. The basic hole has zero lower deviation whereas, the basic shaft has zero upper deviation. Specification of DT Unilateral Tolerance In this system, the dimension of a part is allowed to vary only on one side of the basic size, i.e. tolerance lies wholly on one side of the basic size either above or below it. Bilateral Tolerance In this system, the dimension of the part is allowed to vary on both the sides of the basic size, i.e. the limits of tolerance lie on either side of the basic size. Fit When two parts are to be assembled, the relation resulting from the difference between their sizes before assembly is called a fit. A fit may be defined as the degree of tightness and looseness between two mating parts. Continued...... Numerical Q. For a particular application, an H7 fit has been selected for the hole and a k6 fit for the shaft. The tolerance quoted are 0, +0.025 mm for the hole and +0.012 mm, +0.018 mm for the shaft. Find the upper limit and lower limit for the hole and also for shaft. The basic size of fit is 50 mm. Q. A spindle slides freely in a bush. The basic size of the fit is 50 mm. If the tolerances quoted are 0 ,+0.062 mm for the holes and -0.080 mm, +0.180 mm for the shaft, find the upper limit and lower limit of the shaft and the minimum clearance. Q. A dowel pin is required to be inserted in a base. For this application H 7 fit for hole and a p 6 fit for the shaft are chosen. The tolerance quoted is 0, +0.025 mm for the hole and +0.026 mm, +0.042 mm for the shaft. Find the upper and lower limits of the hole and also dowel pin, and the maximum interference between dowel pin and the hole. The basic size of the fit is 50 mm. Systems of fits A fit system is the systems of standard allowance to suit specific range of basic size. If these standard allowances are selected properly and assigned in mating parts ensures specific classes of fit. There are two systems of fit for obtaining clearance, interference or transition fit. These are: a. Hole basis system b. Shaft basis system Hole Basis System In the hole basis system, the size of the hole is kept constant and shaft sizes are varied to obtain various types of fits. In this system, lower deviation of hole is zero, i.e. the low limit of hole is same as basic size. The high limit of the hole and the two limits of size for the shaft are then varied to give desired type of fit. The hole basis system is commonly used because it is more convenient to make correct holes of fixed sizes, since the standard drills, taps, reamers and branches etc. are available for producing holes and their sizes are not adjustable. On the other hand, size of the shaft produced by turning, grinding, etc. can be very easily varied. Shaft Basis System In the shaft basis system, the size of the shaft is kept constant and different fits are obtained by varying the size of the hole. Shaft basis system is used when the ground bars or drawn bars are readily available. These bars do not require further machining and fits are obtained by varying the sizes of the hole. In this system, the upper deviation (fundamental deviation) of shaft is zero, i.e. the high limit of the shaft is same as basic size and the various fits are obtained by varying the low limit of shaft and both the limits of the hole. What do you mean by 25 H7 f6 or 25H7/f6 32 H7 j6 or 32 H7/j6 40 H7 n6 or 40 H7/n6 ? Continued….. Tolerance grade Grade of Tolerance: It is an indication of the level of accuracy. There are 18 grades of tolerances – IT01, IT0, IT1 to IT16 IT01 to IT4 - For production of gauges, plug gauges, measuring instruments IT5 to IT 7 - For fits in precision engineering applications IT8 to IT11 – For General Engineering IT12 to IT14 – For Sheet metal working or press working IT15 to IT16 – For processes like casting, general cutting work Continued….. **Ref.- machine drawing by K.L Narayana Continued….. Continued….. Numerical Q. Evaluate limits and fits for a pair of Diameter 6 H7/g6. Continued….. Assignment-1 Q1. Evaluate the limits, type of fit and fit parameters for ϕ 20 P7/h6. Show the limits for shaft and hole in the diagram. Q2. Calculate the fundamental deviation, tolerances and limits for the system 50 H7 f7. Show the limits for shaft and hole in the diagram. Q3. Describe about the different mechanical properties and technological properties of engineering materials in detail? Q4. Explain in detail about types of steel and write about the effects of 5 alloying element on steel? Q5. Describe about non-metal (e.g.- plastic) and its types in detail? Q6. Total Strain Energy theory or HAIGH’S THEORY Q7. Maximum Principal Strain theory also known as St. VENANT’S THEORY Types of load The manner of computing the design stress depends on the manner of loading and on the type of material. „ Stress variations are characterized by four key values: – Maximum stress- max ,Minimum stress- min ,Mean (average) stress- m , Alternating stress- a (stress amplitude) Continued….. Continued….. The maximum and minimum stresses are usually computed from known information by stress analysis or finite element methods, or they are measured using experimental stress analysis techniques. „ Then the mean and alternating stresses can be computed from: m max min a max min v var iable stress 2 2 Because of different loading conditions, stress developed in the machine member are; *Tensile stress, *compressive stress, *bending stress, *direct shear stress, *torsional shear stress, *bearing pressure, *crushing stress, *contact stress. Continued….. In machine design, an element is said to have failed if it ceases to perform its function. There are basically two types of mechanical failure: (a) Yielding- This is due to excessive inelastic deformation rendering the machine part unsuitable to perform its function. This mostly occurs in ductile materials. (b) Fracture- in this case the component tears apart in two or more parts. This mostly occurs in brittle materials. There is no sharp line of demarcation between ductile and brittle materials. However a rough guideline is that if percentage elongation is less than 5% then the material may be treated as brittle and if it is more than 5% then the material is ductile. However, there are many instances when a ductile material may fail by fracture. Modes of failure In plane shear Out plane shear Factor of safety